Question: Please help me to do this problem in Process Cost Estimation. Problem 1 A continuous evaporator is used to concentrate a sodium sulfate solution. Over

Please help me to do this problem in Process Cost Estimation.

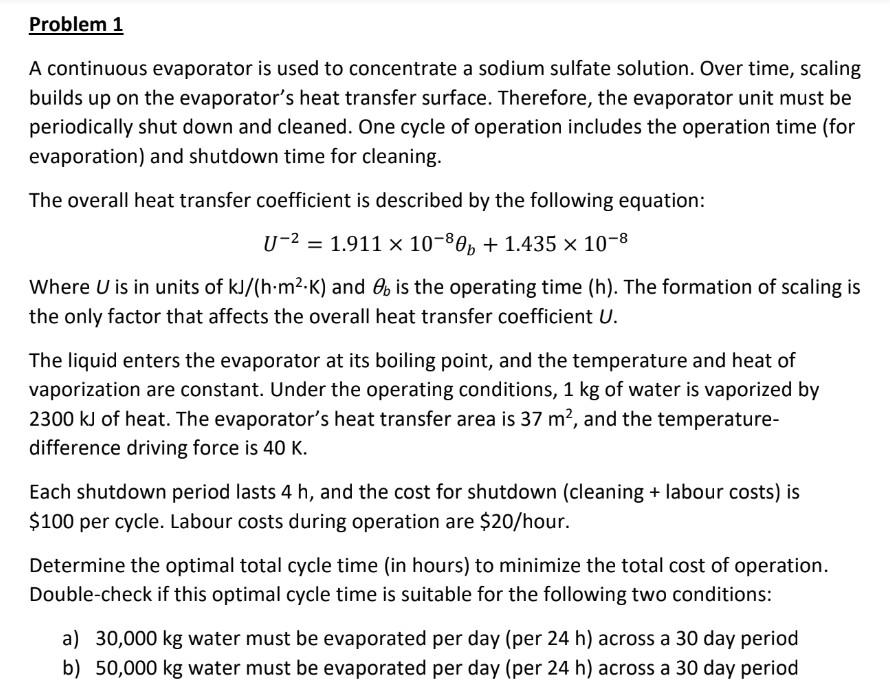

Problem 1 A continuous evaporator is used to concentrate a sodium sulfate solution. Over time, scaling builds up on the evaporator's heat transfer surface. Therefore, the evaporator unit must be periodically shut down and cleaned. One cycle of operation includes the operation time (for evaporation) and shutdown time for cleaning. The overall heat transfer coefficient is described by the following equation: U2=1.911108b+1.435108 Where U is in units of kJ/(hm2K) and b is the operating time (h). The formation of scaling is the only factor that affects the overall heat transfer coefficient U. The liquid enters the evaporator at its boiling point, and the temperature and heat of vaporization are constant. Under the operating conditions, 1kg of water is vaporized by 2300kJ of heat. The evaporator's heat transfer area is 37m2, and the temperaturedifference driving force is 40K. Each shutdown period lasts 4h, and the cost for shutdown (cleaning + labour costs) is $100 per cycle. Labour costs during operation are $20/ hour. Determine the optimal total cycle time (in hours) to minimize the total cost of operation. Double-check if this optimal cycle time is suitable for the following two conditions: a) 30,000kg water must be evaporated per day (per 24h ) across a 30 day period b) 50,000kg water must be evaporated per day (per 24h ) across a 30 day period

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts