Question: Please help me with this question! Clear answers Suppose a certain manufacturing company produces connecting rods for 4- and 6 -cylinder automobile engines using the

Please help me with this question! Clear answers

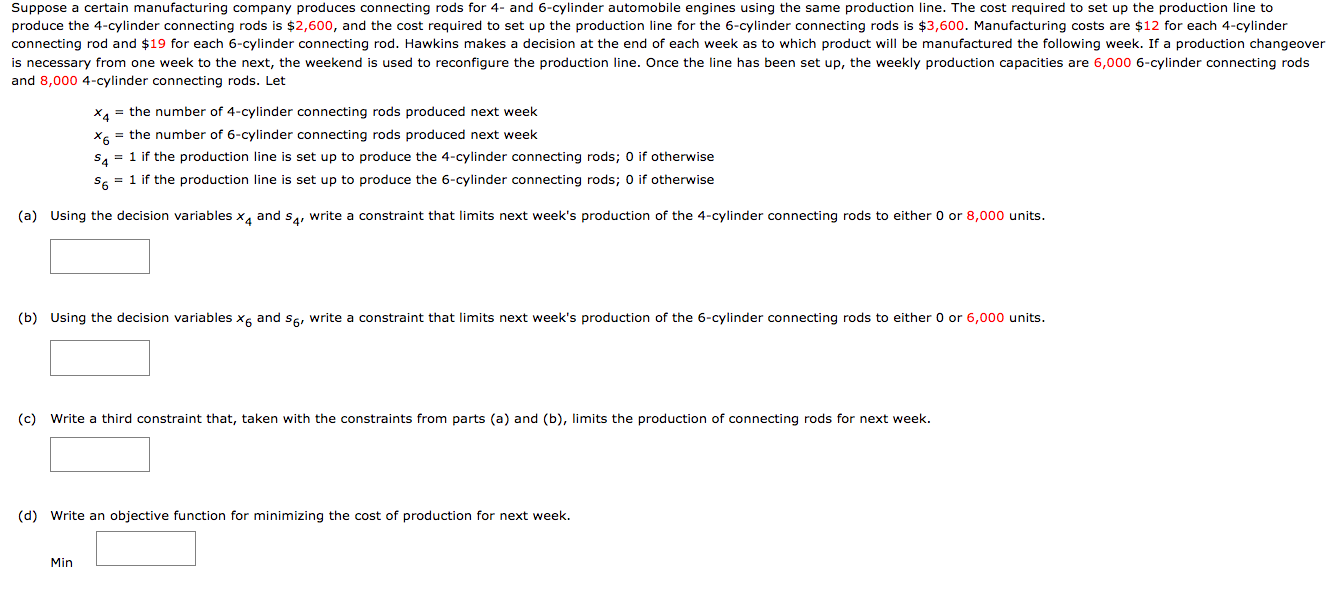

Suppose a certain manufacturing company produces connecting rods for 4- and 6 -cylinder automobile engines using the same production line. The cost required to set up the production line to produce the 4-cylinder connecting rods is $2,600, and the cost required to set up the production line for the 6-cylinder connecting rods is $3,600. Manufacturing costs are $12 for each 4-cylinder connecting rod and $19 for each 6-cylinder connecting rod. Hawkins makes a decision at the end of each week as to which product will be manufactured the following week. If a production changeover is necessary from one week to the next, the weekend is used to reconfigure the production line. Once the line has been set up, the weekly production capacities are 6,0006-cylinder connecting rods and 8,0004 -cylinder connecting rods. Let x4= the number of 4-cylinder connecting rods produced next week x6= the number of 6 -cylinder connecting rods produced next week s4=1 if the production line is set up to produce the 4-cylinder connecting rods; 0 if otherwise s6=1 if the production line is set up to produce the 6-cylinder connecting rods; 0 if otherwise (a) Using the decision variables x4 and s4, write a constraint that limits next week's production of the 4-cylinder connecting rods to either 0 or 8,000 units. (b) Using the decision variables x6 and s6, write a constraint that limits next week's production of the 6 -cylinder connecting rods to either 0 or 6,000 units. (c) Write a third constraint that, taken with the constraints from parts (a) and (b), limits the production of connecting rods for next week. (d) Write an objective function for minimizing the cost of production for next week. Min Suppose a certain manufacturing company produces connecting rods for 4- and 6 -cylinder automobile engines using the same production line. The cost required to set up the production line to produce the 4-cylinder connecting rods is $2,600, and the cost required to set up the production line for the 6-cylinder connecting rods is $3,600. Manufacturing costs are $12 for each 4-cylinder connecting rod and $19 for each 6-cylinder connecting rod. Hawkins makes a decision at the end of each week as to which product will be manufactured the following week. If a production changeover is necessary from one week to the next, the weekend is used to reconfigure the production line. Once the line has been set up, the weekly production capacities are 6,0006-cylinder connecting rods and 8,0004 -cylinder connecting rods. Let x4= the number of 4-cylinder connecting rods produced next week x6= the number of 6 -cylinder connecting rods produced next week s4=1 if the production line is set up to produce the 4-cylinder connecting rods; 0 if otherwise s6=1 if the production line is set up to produce the 6-cylinder connecting rods; 0 if otherwise (a) Using the decision variables x4 and s4, write a constraint that limits next week's production of the 4-cylinder connecting rods to either 0 or 8,000 units. (b) Using the decision variables x6 and s6, write a constraint that limits next week's production of the 6 -cylinder connecting rods to either 0 or 6,000 units. (c) Write a third constraint that, taken with the constraints from parts (a) and (b), limits the production of connecting rods for next week. (d) Write an objective function for minimizing the cost of production for next week. Min

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts