Question: Please help, Thank You. Review the proposal from Bob McCarthy shown in Case Exhibit 4. Does his analysis contain any erroneous assumptions? For instance, his

Please help, Thank You.

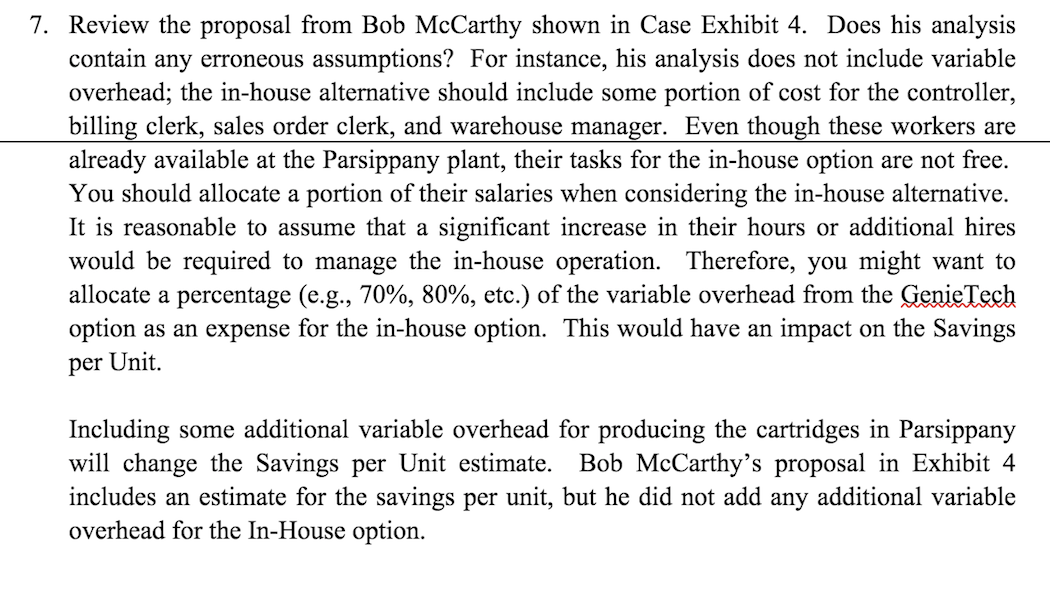

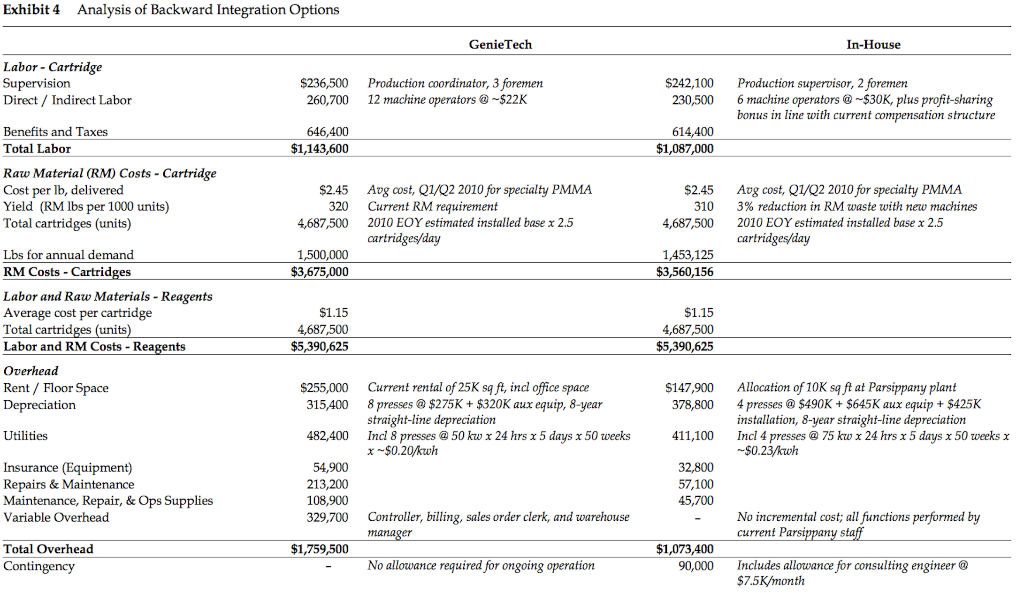

Review the proposal from Bob McCarthy shown in Case Exhibit 4. Does his analysis contain any erroneous assumptions? For instance, his analysis does not include variable overhead; the in-house alternative should include some portion of cost for the controller, billing clerk, sales order clerk, and warehouse manager. Even though these workers are already available at the Parsippany plant, their tasks for the in-house option are not free. You should allocate a portion of their salaries when considering the in-house alternative. It is reasonable to assume that a significant increase in their hours or additional hires would be required to manage the in-house operation. Therefore, you might want to allocate a percentage (e.g., 70\%, 80\%, etc.) of the variable overhead from the GenieTech option as an expense for the in-house option. This would have an impact on the Savings per Unit. Including some additional variable overhead for producing the cartridges in Parsippany will change the Savings per Unit estimate. Bob McCarthy's proposal in Exhibit 4 includes an estimate for the savings per unit, but he did not add any additional variable overhead for the In-House option. Exhibit 4 Analysis of Backward Integration Options Exhibit 4 Analysis of Backward Integration Options (cont.) GenieTech In-House Comparison of Cost per Unit Labor Raw Materials Reagents Costs Overhead Contingency $1,143,6003,675,0005,390,6251,759,500$1,087,0003,560,1565,390,6251,073,40090,000 Annual Operating Cost $11,968,725 $11,201,181 Annual Production of Cartridges 4,687,500 4,687,500 Cost per Unit $2.553 Current Cost per Unit, Delivered Cost per Unit, Bergerac $2.960 $2.703 Includes delivery costs (transportation, fuel, handling) of $0.15/ unit Savings per Unit Annual Savings @ Current Production $0.257 $1,204,688 Capital Requirements Acquisition Price $5,750,000 Based on 5x EBITDA multiple Machinery \& Equipment Molding Machines Cost 375,000 Estimated cost for new Hitachi molding machine Molds 115,000 Cartridge cover and base molds for each molding machine Number of Molding Machines Installation Cost Quoted installation cost Auxiliary Equipment Contingency Allowance of 5% of total capital investment in equipment Building \& Building Equipment Total Capital Requirements $5,750,000 Savings per Unit $0.257 Break-Even Volume Annual Production Volume 22,373,541 4,687,500 Payback Period, Years 4.8 Review the proposal from Bob McCarthy shown in Case Exhibit 4. Does his analysis contain any erroneous assumptions? For instance, his analysis does not include variable overhead; the in-house alternative should include some portion of cost for the controller, billing clerk, sales order clerk, and warehouse manager. Even though these workers are already available at the Parsippany plant, their tasks for the in-house option are not free. You should allocate a portion of their salaries when considering the in-house alternative. It is reasonable to assume that a significant increase in their hours or additional hires would be required to manage the in-house operation. Therefore, you might want to allocate a percentage (e.g., 70\%, 80\%, etc.) of the variable overhead from the GenieTech option as an expense for the in-house option. This would have an impact on the Savings per Unit. Including some additional variable overhead for producing the cartridges in Parsippany will change the Savings per Unit estimate. Bob McCarthy's proposal in Exhibit 4 includes an estimate for the savings per unit, but he did not add any additional variable overhead for the In-House option. Exhibit 4 Analysis of Backward Integration Options Exhibit 4 Analysis of Backward Integration Options (cont.) GenieTech In-House Comparison of Cost per Unit Labor Raw Materials Reagents Costs Overhead Contingency $1,143,6003,675,0005,390,6251,759,500$1,087,0003,560,1565,390,6251,073,40090,000 Annual Operating Cost $11,968,725 $11,201,181 Annual Production of Cartridges 4,687,500 4,687,500 Cost per Unit $2.553 Current Cost per Unit, Delivered Cost per Unit, Bergerac $2.960 $2.703 Includes delivery costs (transportation, fuel, handling) of $0.15/ unit Savings per Unit Annual Savings @ Current Production $0.257 $1,204,688 Capital Requirements Acquisition Price $5,750,000 Based on 5x EBITDA multiple Machinery \& Equipment Molding Machines Cost 375,000 Estimated cost for new Hitachi molding machine Molds 115,000 Cartridge cover and base molds for each molding machine Number of Molding Machines Installation Cost Quoted installation cost Auxiliary Equipment Contingency Allowance of 5% of total capital investment in equipment Building \& Building Equipment Total Capital Requirements $5,750,000 Savings per Unit $0.257 Break-Even Volume Annual Production Volume 22,373,541 4,687,500 Payback Period, Years 4.8

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts