Question: Please help! The table on the bottom is from a different problem but this is how they're asking for it to be done. I'm having

Please help! The table on the bottom is from a different problem but this is how they're asking for it to be done. I'm having a hard time understanding how to work it out with this table.

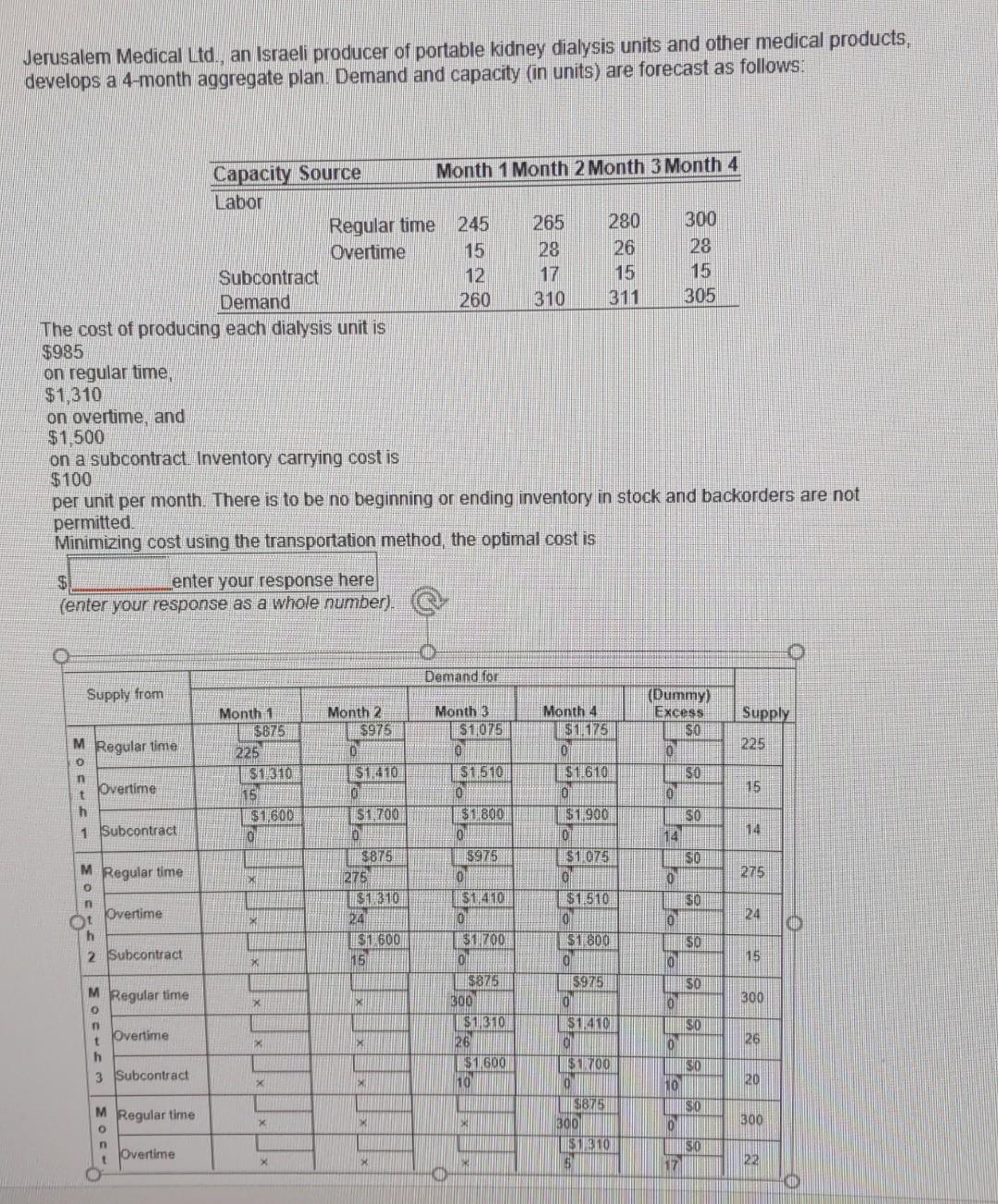

Jerusalem Medical Ltd., an Israeli producer of portable kidney dialysis units and other medical products, develops a 4-month aggregate plan. Demand and capacity (in units) are forecast as follows: Capacity Source Month 1 Month 2 Month 3 Month 4 Labor Regular time 245 265 280 300 Overtime 15 28 26 28 Subcontract 12 17 15 15 Demand 260 310 311 305 The cost of producing each dialysis unit is $985 on regular time, $1,310 on overtime, and $1.500 on a subcontract Inventory carrying cost is $100 per unit per month. There is to be no beginning or ending inventory in stock and backorders are not permitted Minimizing cost using the transportation method, the optimal cost is enter your response here (enter your response as a whole number). @ Demand for Supply from Month 1 $875 Month 2 $975 D $1.410 Supply 225 M Regular time 225 OE- 15 n It Overtime h 1 Subcontract $14310 15 $1,600 0 (Dummy) Excess 50 0 SO 0 SO 14 SO 0 ISO 0 14 275 X M Regular time 0 n Overtime h 2 Subcontract Month 3 S1075 0 $1,510 0 $1800 0 $975 0 $1,410 0 31700 ON $875 300 51310) 126 $1,600 10 S1,700 0 $8751 275 S1310 24 36007 15 124 Month 4 $1,175 0 $1.610 0 $1.900 10 $ 1075 0 $1.510 10 $1 8002 d 5975 0 S1410 ON $ 1700 0 $875 3001 ST310 15 X M Regular time X X 300 o x X 26 Overtime t h 3 Subcontract SO 0 SO 10 SO TOM 30 10 ISO 0 SO 17 X X 20 M Regular time x 300 O n Overtime x X 122Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts