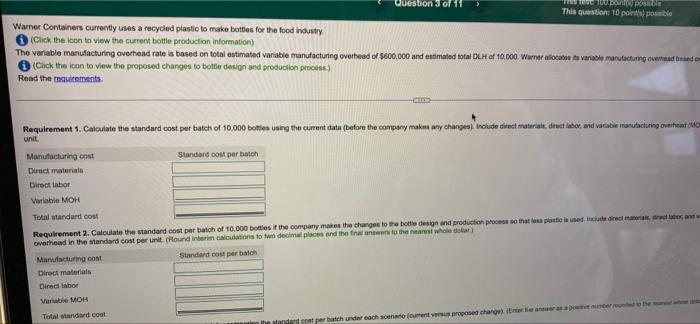

Question: please help with the clear steps to understand this questions . thank you Question 3 of 11 This tabe 100 pontosable This question: 10 points)

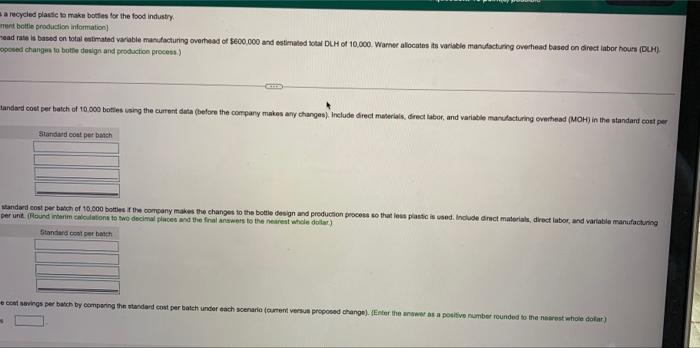

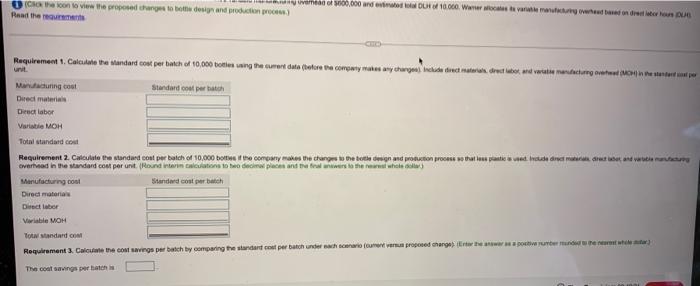

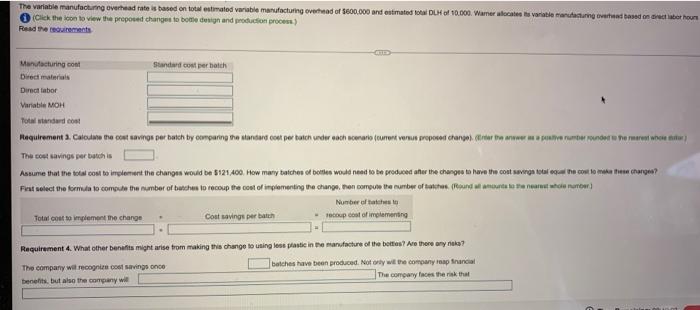

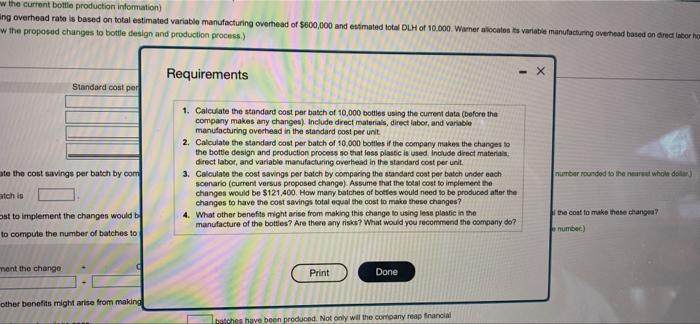

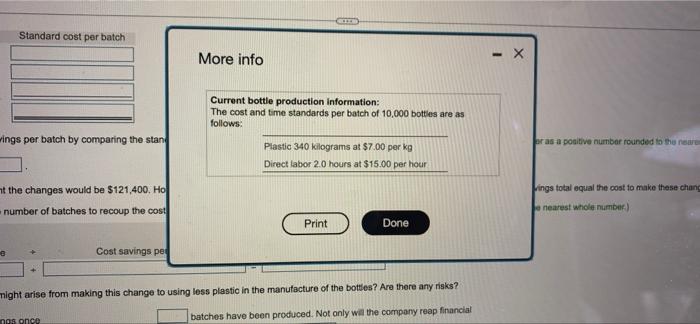

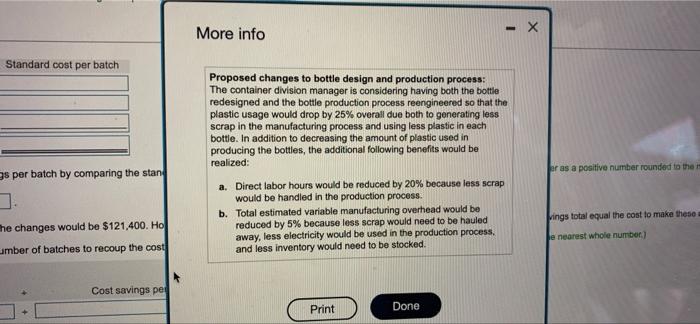

Question 3 of 11 This tabe 100 pontosable This question: 10 points) possible Warner Containers currently uses a recycled plastic to make bottles for the food industry (Click the icon to view the current bottle production information) The variable manufacturing overhead rate is based on total estimated variable manufacturing overhead of $600,000 and estimated total DLH of 10.000. Warner allocates its variable manufacturing overhead based on (Click the icon to view the proposed changes to bottle design and production process.) Read the requirements. Requirement 1. Calculate the standard cost per batch of 10,000 bottles using the current data (before the company makes any changes). Include direct materials, direct labor, and variable manufacturing overhead (MO unit. Standard cost per batch Manufacturing cost Direct materials Direct labor Variable MOH Total standard cost Requirement 2. Calculate the standard cost per batch of 10,000 bottles if the company makes the changes to the bottle design and production process so that less plastic is used include direct materials, direct laber, and w overhead in the standard cost per unit (Round interim calculations to two decimal places and the final answers to the nearest whole dollar) Manufacturing cost Standard cost per batch Direct materials Direct labor Variable MOH Total standard cost the standard coet per batch under each scenario (cument versus proposed change) (Enter the answer as a positive number rounded to the w sa recycled plastic to make bottles for the food industry. ment bottle production information) mead rate is based on total estimated variable manufacturing overhead of $600,000 and estimated total DLH of 10,000. Wamer allocates its variable manufacturing overhead based on direct labor hours (DLH) oposed changes to bottle design and production process) tandard cost per batch of 10.000 bottles using the current data (before the company makes any changes). Include direct materials, direct labor, and variable manufacturing overhead (MOH) in the standard cost per Standard cost per batch standard cost per batch of 10,000 bottles if the company makes the changes to the bottle design and production process so that less plastic is used. Include direct materials, direct labor, and variable manufacturing per unit. (Round interim calculations to two decimal places and the final answers to the nearest whole dollar) Standard cost per batch e cost savings per batch by comparing the standard cost per batch under each scenario (oument versus proposed change). (Enter the answer as a positive number rounded to the nearest whole dolar) N verhead of 5000,000 and estimated total DLH of 10.000 Wamer allocates ta variable manufacturing overhead based on direct stor houn DUB (Click the icon to view the proposed changes to bottle design and production process.) Read the requirements Requirement 1. Calculate the standard cost per batch of 10,000 boties using the cument data (before the company makes any changes include direct materials, direct labore unit. wiate manufacturing overhed (MCH) in the str Manufacturing cost Standard cost per batch Direct materials Direct labor Variable MOH Total standard cost Requirement 2. Calculate the standard cost per batch of 10,000 bottles if the company makes the changes to the botle design and production process so that less plastic is used include direct mataas direct beta wwamaturg overhead in the standard cost per unit. (Round interim calculations to beo decimal places and the final answers to the near whole dollar) Manufacturing cost Standard cost per batch Direct materials Direct labor Variable MOH Total standard cost Requirement 3. Calculate the cost savings per batch by comparing the standard cost per batch under each scenario (oument versus proposed change) (Enter the answer as a positive rumber munded to the nearest wher The cost savings per batch is The variable manufacturing overhead rate is based on total estimated variable manufacturing overhead of $600,000 and estimated total DLH of 10.000. Wamer allocates its variable manufacturing overhead based on direct labor hours (Click the loon to view the proposed changes to bottle design and production process) Read the requirements CITE Manufacturing cost Standard cost per batch Direct materials Direct labor Variable MOH Total standard cost Requirement 3. Calculate the cost savings per batch by comparing the standard cost per batch under each scenario (current versus proposed change). Enter the answer as a positive number rounded to the rearest whole r The cost savings per batch is Assume that the total cost to implement the changes would be $121,400. How many batches of bottles would need to be produced after the changes to have the cost savings total equal the cost to make these changes? First select the formula to compute the number of batches to recoup the cost of implementing the change, then compute the number of batches (Round all amounts to the nearest whole number) Number of batches to recoup cost of implementing Total cost to implement the change Cost savings per batch Requirement 4. What other benefits might arise from making this change to using less plastic in the manufacture of the bottos? Are there any naks? batches have been produced. Not only will the company reap financial The company faces the risk that The company will recognize cost savings once benefits, but also the company will w the current bottle production information) ng overhead rate is based on total estimated variable manufacturing overhead of $600,000 and estimated total DLH of 10.000. Warner allocates its variable manufacturing overhead based on direct labor hom w the proposed changes to bottle design and production process.) Requirements

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts