Question: Please help with this case study. What are the main arguments you need to counter? What is at stake for each key player? What levers

Please help with this case study.

- What are the main arguments you need to counter?

- What is at stake for each key player?

- What levers can you use to influence those who disagree with you?

- What is the most powerful response you can offer? What is the best context for this response?

Determine an approach to resolving the problems in the case by imagining how the conversation between the protagonist and the antagonist might go if you (the protagonist) were to speak up to them about your beliefs regarding the resolution of this problem. Then, distill the lessons learned into a memorandum addressed to the antagonist, which summarizes the conversation (I wanted to follow up on our conversation with this written summary to be sure we are on the same page going forward.)

Specifically, this memorandum should:

- Recount the way in which the protagonist expressed his or her values (of course, an actual conversation didn't take place, so describe the main points of the conversation you think should have occurred).

- Address the scripting questions presented in the introductory lecture.

- Carefully and effectively use language to convey the protagonist's exact intent.

This case report is not just about resolving an ethical problem, but also about leveraging the breadth and depth of work weve done so far to design our future approach to business challenges.

Please present this work in office memo form. Memos should be approximately 2 pages (double-spaced) and should be written in a clear, careful, and concise manner.

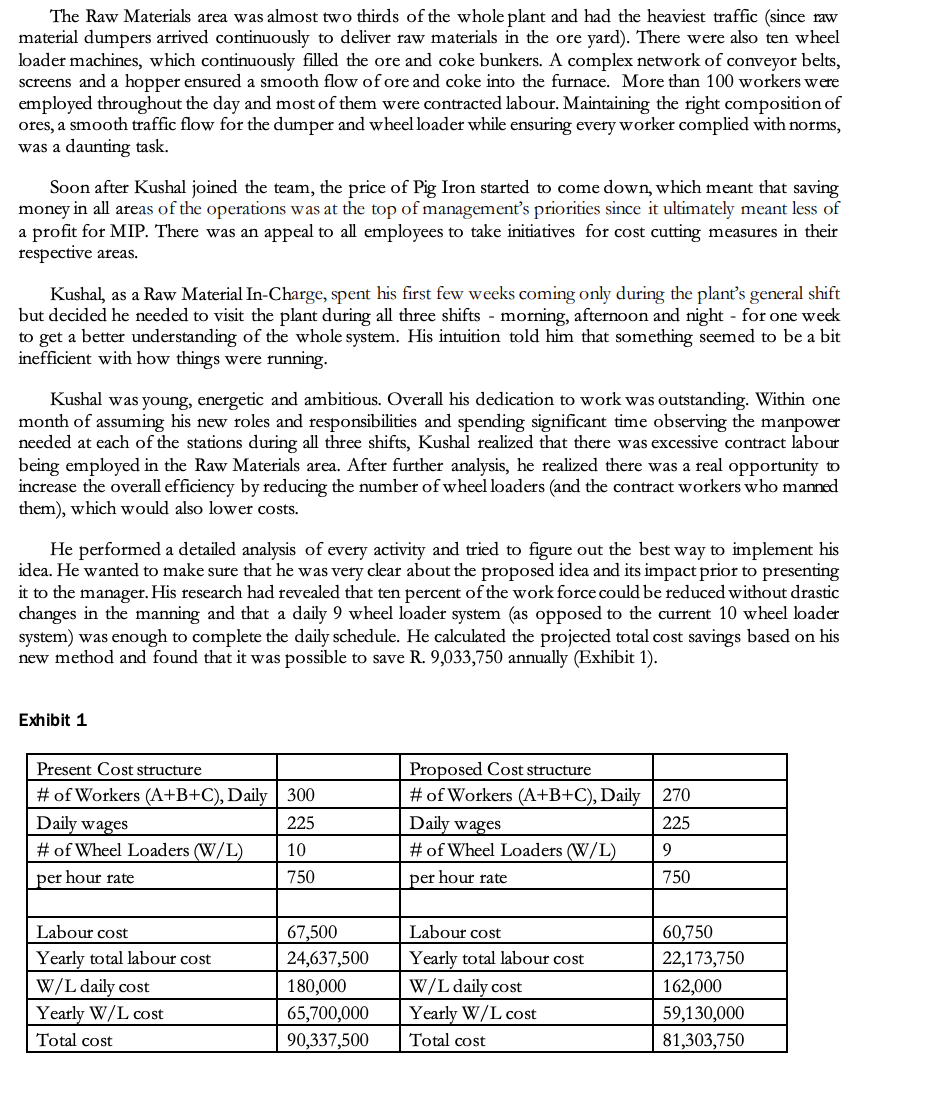

When the Boss is the Barrier (A)1,2 Kushal, a metallurgist from Bengal Engineering and Science University, was sitting pensively in his cubicle at Marcel Iron Plant (MIP). His job as a Raw Material Handling In-Charge had given him a range of responsibilities ranging from managing people to understanding the technical complexities of the iron plant to running the full operations. He had established a reputation for being a smart, energetic and a proactive engineer and was in line to get a promotion soon. As he mulled overhis current dilemma, whether to take the risk of going against the manager or keep silent, he reflected on the many challenges he had faced during his time with the organisation so far. Background After working for more than two years in an aluminum plant within the same firm in Orissa, Kushal had recently been transferred to Goa to work with MIP. On his very first day at MIP he was introduced to the General Manager (GM) and to the Associate Vice President (AVP) who served as the plant head. The GM offered to take Kushal on a plant visit, during which the organisational structure (both in terms of hierarchy and departmentalization) was explained to him. The GM came under the plant head and was responsible for all of the operational activities. The plant was divided into three departments, the Raw Material Yard, the Blast Furnace, and the Cast House 3. The GM took Kushal into the Raw Material Yard and familiarised him with all the equipment. He explained the importance of the Raw Material Yard as it related to the entire supply chain of the plant. The GM also explained the process that took place at the Blast Furnace (where liquid metal was produced from the iron ore). They also visited the Cast House before returning to the GM's office. After a brief introduction to all of the department managers, Kushal was assigned to report to the Raw Material Manager as the Raw Material Handling Area In-Charge. Kushal's subsequent yard visits and conversations with his new Boss helped him learn more about his new department and how it functioned, what work was required at each station, the safety guidelines and how many people were required for each of the activities. material dumpers arrived continuously to deliver raw materials in the ore yard). There were also ten wheel loader machines, which continuously filled the ore and coke bunkers. A complex network of conveyor belts, screens and a hopper ensured a smooth flow of ore and coke into the furnace. More than 100 workers were employed throughout the day and most of them were contracted labour. Maintaining the right composition of ores, a smooth traffic flow for the dumper and wheel loader while ensuring every worker complied with norms, was a daunting task. Soon after Kushal joined the team, the price of Pig Iron started to come down, which meant that saving money in all areas of the operations was at the top of management's priorities since it ultimately meant less of a profit for MIP. There was an appeal to all employees to take initiatives for cost cutting measures in their respective areas. Kushal, as a Raw Material In-Charge, spent his first few weeks coming only during the plant's general shift but decided he needed to visit the plant during all three shifts - morning, afternoon and night - for one week to get a better understanding of the whole system. His intuition told him that something seemed to be a bit inefficient with how things were running. Kushal was young, energetic and ambitious. Overall his dedication to work was outstanding. Within one month of assuming his new roles and responsibilities and spending significant time observing the manpower needed at each of the stations during all three shifts, Kushal realized that there was excessive contract labour being employed in the Raw Materials area. After further analysis, he realized there was a real opportunity to increase the overall efficiency by reducing the number of wheel loaders (and the contract workers who manned them), which would also lower costs. He performed a detailed analysis of every activity and tried to figure out the best way to implement his idea. He wanted to make sure that he was very clear about the proposed idea and its impact prior to presenting it to the manager. His research had revealed that ten percent of the work force could be reduced without drastic changes in the manning and that a daily 9 wheel loader system (as opposed to the current 10 wheel loader system) was enough to complete the daily schedule. He calculated the projected total cost savings based on his new method and found that it was possible to save R. 9,033,750 annually (Exhibit 1). Exhibit 1 Kushal's Interaction with his Manager Kushal was excited with his findings and was sure that his idea would be appreciated by his superiors. The next morning, he visited his manager to present his research and proposal. He had expected a positive response from his manager in light of his efforts and the potential cost savings. He was confident he could maintain the daily schedule of work without any interruption while simultaneously reducing the number of wheel loaders and workers in that area. After Kushal presented the plan to his manager, to his surprise, he faced his manager's wrath. The manager rejected Kushal's finding without studying them and dismissively remarked that the plant was running smoothly and Kushal had no reason to tweak the manpower nor the number of wheel loaders. He told Kushal that since he had only recently joined the team he did not understand the complexities of the department. Kushal tried his best to explain that cost cutting was the only way to survive in a competitive environment and that they should try implementing his recommendations for just one week before deciding the efficacy of the proposal, especially due to the potential yearly savings of roughly ninety lakhs rupees. But, the manager was adamant and insisted Kushal leave his office. Kushal's Dilemma Kushal sat in his cubicle trying to figure out the rationale behind his manager's behaviour. They had always had a very professional and courteous relationship and this behaviour seemed out of place. Kushal had done a thorough job at researching and calculating the proposed plan and was confident it was well worth at least a look, especially given the appeal to employees to offer cost savings ideas. His manager's reaction simply did not make sense and Kushal's intuition again told him there must be something more to the unwillingness to even discuss it. Kushal was determined to figure out why his boss had been so unwilling to even look at the numbers, let alone talk through the proposal with him or pilot his idea for a week. Did the manager really think the proposal was impractical or was there something more to it? The next day, he started informally investigating within the department about the possible reasons for the managers' apprehensions to reduce manpower. He spoke to the previous In- Charges but everyone was lip locked and no one commented on the manager's behaviour. In the subsequent days, Kushal noticed changes in the way his manager was interacting with him. Kushal noticed that his manager hardly spoke to him and apart from taking reports from him, he largely avoided Kushal. Not reading too much into it, Kushal carried on his good work and tried to infuse discipline in the department. Nevertheless, he couldn't stop wondering why his manager was behaving this way. After all, what Kushal had proposed was for the greater good of the organization and could easily be implemented for a week and then changed again if it did not have the predicted impact. After a few days, Kushal was still perplexed and unsure of what to do. Should he speak to the GM? Should he try to convince his manager once more? He had no doubt that his proposal was sound and based on accurate calculations, but it had only been done through estimation and it still needed to be proven practically. The following week, Kushal's manager started a 10 -day vacation and Kushal was to report temporarily to the Cast House Head who was also acting as Manager of the Raw Material Handling Department during his superior's absence. The acting manager, busy with his original department, hardly visited the Raw Material Yard. Kushal realised that this might be a perfect opportunity to experiment with his proposed plan. He took a risk and he relieved 10 workers and one wheel loader in every shift. He spoke with all of the shift In-Charges and asked them to follow his plan until further notice. He started spending 16-18 hours a day in the plant to closely monitor his new work plan. He didn't face any difficulties and that gave him a lot of confidence. Kushal gradually became familiar with every nook and corner of the Raw Material Yard and he was convinced that his proposal was working. Since his manager had already started behaving differently, Kushal feared that raising this issue with him again would have further tainted their relationship and possibly put his job at risk. Kushal was determined to bring his findings to the notice of the higher management now that he was in a position to demonstrate his idea with the addition of proven results. But, he wanted to better understand the hiring process for the contract labour before bringing his findings to the higher ups. When the Boss is the Barrier (A)1,2 Kushal, a metallurgist from Bengal Engineering and Science University, was sitting pensively in his cubicle at Marcel Iron Plant (MIP). His job as a Raw Material Handling In-Charge had given him a range of responsibilities ranging from managing people to understanding the technical complexities of the iron plant to running the full operations. He had established a reputation for being a smart, energetic and a proactive engineer and was in line to get a promotion soon. As he mulled overhis current dilemma, whether to take the risk of going against the manager or keep silent, he reflected on the many challenges he had faced during his time with the organisation so far. Background After working for more than two years in an aluminum plant within the same firm in Orissa, Kushal had recently been transferred to Goa to work with MIP. On his very first day at MIP he was introduced to the General Manager (GM) and to the Associate Vice President (AVP) who served as the plant head. The GM offered to take Kushal on a plant visit, during which the organisational structure (both in terms of hierarchy and departmentalization) was explained to him. The GM came under the plant head and was responsible for all of the operational activities. The plant was divided into three departments, the Raw Material Yard, the Blast Furnace, and the Cast House 3. The GM took Kushal into the Raw Material Yard and familiarised him with all the equipment. He explained the importance of the Raw Material Yard as it related to the entire supply chain of the plant. The GM also explained the process that took place at the Blast Furnace (where liquid metal was produced from the iron ore). They also visited the Cast House before returning to the GM's office. After a brief introduction to all of the department managers, Kushal was assigned to report to the Raw Material Manager as the Raw Material Handling Area In-Charge. Kushal's subsequent yard visits and conversations with his new Boss helped him learn more about his new department and how it functioned, what work was required at each station, the safety guidelines and how many people were required for each of the activities. material dumpers arrived continuously to deliver raw materials in the ore yard). There were also ten wheel loader machines, which continuously filled the ore and coke bunkers. A complex network of conveyor belts, screens and a hopper ensured a smooth flow of ore and coke into the furnace. More than 100 workers were employed throughout the day and most of them were contracted labour. Maintaining the right composition of ores, a smooth traffic flow for the dumper and wheel loader while ensuring every worker complied with norms, was a daunting task. Soon after Kushal joined the team, the price of Pig Iron started to come down, which meant that saving money in all areas of the operations was at the top of management's priorities since it ultimately meant less of a profit for MIP. There was an appeal to all employees to take initiatives for cost cutting measures in their respective areas. Kushal, as a Raw Material In-Charge, spent his first few weeks coming only during the plant's general shift but decided he needed to visit the plant during all three shifts - morning, afternoon and night - for one week to get a better understanding of the whole system. His intuition told him that something seemed to be a bit inefficient with how things were running. Kushal was young, energetic and ambitious. Overall his dedication to work was outstanding. Within one month of assuming his new roles and responsibilities and spending significant time observing the manpower needed at each of the stations during all three shifts, Kushal realized that there was excessive contract labour being employed in the Raw Materials area. After further analysis, he realized there was a real opportunity to increase the overall efficiency by reducing the number of wheel loaders (and the contract workers who manned them), which would also lower costs. He performed a detailed analysis of every activity and tried to figure out the best way to implement his idea. He wanted to make sure that he was very clear about the proposed idea and its impact prior to presenting it to the manager. His research had revealed that ten percent of the work force could be reduced without drastic changes in the manning and that a daily 9 wheel loader system (as opposed to the current 10 wheel loader system) was enough to complete the daily schedule. He calculated the projected total cost savings based on his new method and found that it was possible to save R. 9,033,750 annually (Exhibit 1). Exhibit 1 Kushal's Interaction with his Manager Kushal was excited with his findings and was sure that his idea would be appreciated by his superiors. The next morning, he visited his manager to present his research and proposal. He had expected a positive response from his manager in light of his efforts and the potential cost savings. He was confident he could maintain the daily schedule of work without any interruption while simultaneously reducing the number of wheel loaders and workers in that area. After Kushal presented the plan to his manager, to his surprise, he faced his manager's wrath. The manager rejected Kushal's finding without studying them and dismissively remarked that the plant was running smoothly and Kushal had no reason to tweak the manpower nor the number of wheel loaders. He told Kushal that since he had only recently joined the team he did not understand the complexities of the department. Kushal tried his best to explain that cost cutting was the only way to survive in a competitive environment and that they should try implementing his recommendations for just one week before deciding the efficacy of the proposal, especially due to the potential yearly savings of roughly ninety lakhs rupees. But, the manager was adamant and insisted Kushal leave his office. Kushal's Dilemma Kushal sat in his cubicle trying to figure out the rationale behind his manager's behaviour. They had always had a very professional and courteous relationship and this behaviour seemed out of place. Kushal had done a thorough job at researching and calculating the proposed plan and was confident it was well worth at least a look, especially given the appeal to employees to offer cost savings ideas. His manager's reaction simply did not make sense and Kushal's intuition again told him there must be something more to the unwillingness to even discuss it. Kushal was determined to figure out why his boss had been so unwilling to even look at the numbers, let alone talk through the proposal with him or pilot his idea for a week. Did the manager really think the proposal was impractical or was there something more to it? The next day, he started informally investigating within the department about the possible reasons for the managers' apprehensions to reduce manpower. He spoke to the previous In- Charges but everyone was lip locked and no one commented on the manager's behaviour. In the subsequent days, Kushal noticed changes in the way his manager was interacting with him. Kushal noticed that his manager hardly spoke to him and apart from taking reports from him, he largely avoided Kushal. Not reading too much into it, Kushal carried on his good work and tried to infuse discipline in the department. Nevertheless, he couldn't stop wondering why his manager was behaving this way. After all, what Kushal had proposed was for the greater good of the organization and could easily be implemented for a week and then changed again if it did not have the predicted impact. After a few days, Kushal was still perplexed and unsure of what to do. Should he speak to the GM? Should he try to convince his manager once more? He had no doubt that his proposal was sound and based on accurate calculations, but it had only been done through estimation and it still needed to be proven practically. The following week, Kushal's manager started a 10 -day vacation and Kushal was to report temporarily to the Cast House Head who was also acting as Manager of the Raw Material Handling Department during his superior's absence. The acting manager, busy with his original department, hardly visited the Raw Material Yard. Kushal realised that this might be a perfect opportunity to experiment with his proposed plan. He took a risk and he relieved 10 workers and one wheel loader in every shift. He spoke with all of the shift In-Charges and asked them to follow his plan until further notice. He started spending 16-18 hours a day in the plant to closely monitor his new work plan. He didn't face any difficulties and that gave him a lot of confidence. Kushal gradually became familiar with every nook and corner of the Raw Material Yard and he was convinced that his proposal was working. Since his manager had already started behaving differently, Kushal feared that raising this issue with him again would have further tainted their relationship and possibly put his job at risk. Kushal was determined to bring his findings to the notice of the higher management now that he was in a position to demonstrate his idea with the addition of proven results. But, he wanted to better understand the hiring process for the contract labour before bringing his findings to the higher ups

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts