Question: please I need a detailed solution. Thanks. Quality Control Exercise for OM Explorer PART 1: Control Charts Bobcat Manufacturing Company prides itself on the quality

please I need a detailed solution. Thanks.

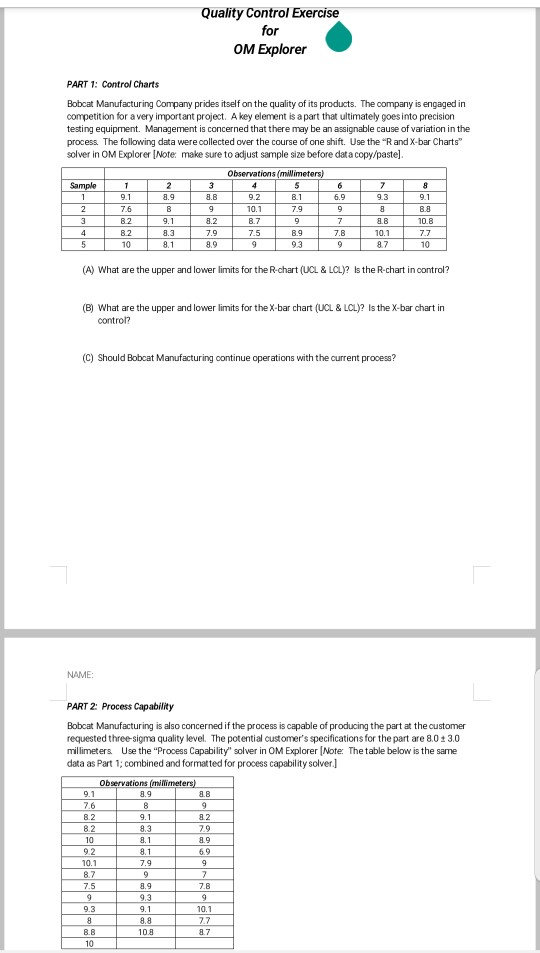

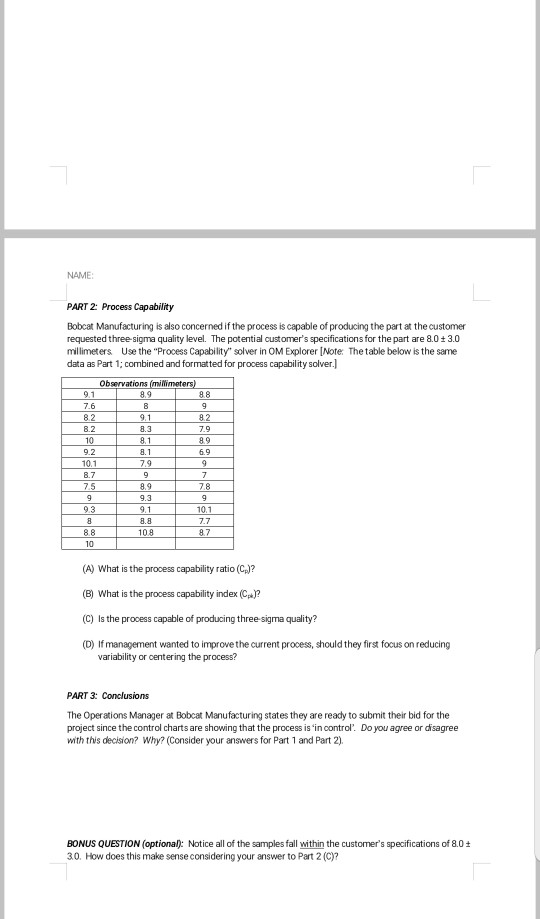

Quality Control Exercise for OM Explorer PART 1: Control Charts Bobcat Manufacturing Company prides itself on the quality of its products. The company is engaged in competition for a very important project. A key element is a part that ultimately goes into precision testing equipment. Management is concerned that there may be an assignable cause of variation in the process. The following data were collected over the course of one shift. Use the "Rand X-bar Charts" solver in OM Explorer [Note: make sure to adjust sample size before data copy/paste]. Observations (milimeters) Sample 9.1 8.9 8.8 9.2 8.1 6.9 9.3 9.1 7.6 10.1 7.9 B.8 B.2 9.1 8.2 B.7 8.8 10.8 4 8.2 8.3 7.9 7.5 8.9 7.8 10.1 7.7 10 8.1 8.9 9.3 8.7 10 (A) What are the upper and lower limits for the R-chart (UCL & LCL)? Is the R-chart in control? (B) What are the upper and lower limits for the X-bar chart (UCL & LCL)? Is the X-bar chart in control? (C) Should Bobcat Manufacturing continue operations with the current process? NAME: PART 2: Process Capability Bobcat Manufacturing is also concerned if the process is capable of producing the part at the customer requested three-sigma quality level. The potential customer's specifications for the part are 8.0 1 3.0 millimeters. Use the "Process Capability" solver in OM Explorer (Note: The table below is the same data as Part 1; combined and formatted for process capability solver.] Observations (milimeters) 9.1 8.9 8.8 7.6 8.2 9.1 8.2 8.2 8.3 7.9 10 8.1 8.9 9.2 8.1 6.9 10.1 7.9 8.7 7.5 8.9 7.8 9.3 9.3 9.1 10.1 8.8 7.7 B.B 10.8 8.7 10 NAME: PART 2: Process Capability Bobcat Manufacturing is also concerned if the process is capable of producing the part at the customer requested three sigma quality level. The potential customer's specifications for the part are 8.0 + 3.0 millimeters. Use the "Process Capability" solver in OM Explorer [Note: The table below is the same data as Part 1; combined and formatted for process capability solver.] Observations (millimeters) 8.9 9.1 8.8 7.6 8.2 9.1 8.2 8.2 8.3 7.9 8.1 10 8.9 9.2 8.1 6.9 10.1 7.9 8.7 7.5 8.9 7.8 9.3 9.3 9.1 10.1 7.7 8.8 10.8 8.8 8.7 10 (A) What is the process capability ratio (C,)? (B) What is the process capability index (Ca)? (C) Is the process capable of producing three sigma quality? (D) If management wanted to improve the current process, should they first focus on reducing variability or centering the process? PART 3: Conclusions The Operations Manager at Bobcat Manufacturing states they are ready to submit their bid for the project since the control charts are showing that the process is 'in control'. Do you agree or disagree with this decision? Why? (Consider your answers for Part 1 and Part 2). BONUS QUESTION (optional): Notice all of the samples fall within the customer's specifications of 8.0 + 3.0. How does this make sense considering your answer to Part 2 (C)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock