Question: Please, I need it step by step and clear answer, solving by Excel is better with the calculations Question 3: (a) KANJAR Company is a

Please, I need it step by step and clear answer, solving by Excel is better with the calculations

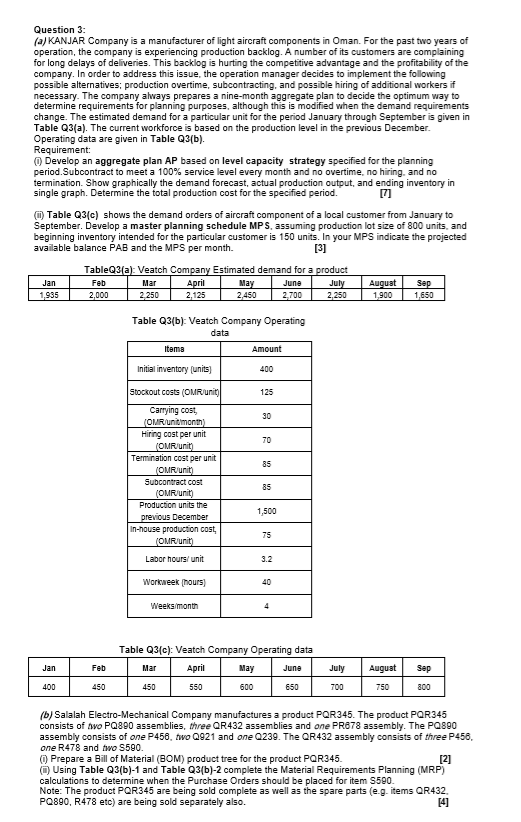

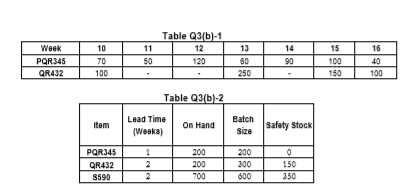

Question 3: (a) KANJAR Company is a manufacturer of light aircraft components in Oman. For the past two years of operation, the company is experiencing production backlog. A number of its customers are complaining for long delays of deliveries. This backlog is hurting the competitive advantage and the profitability of the company. In order to address this issue, the operation manager decides to implement the following possible alternatives; production overtime, subcontracting, and possible hiring of additional workers if necessary. The company always prepares a nine-month aggregate plan to decide the optimum way to determine requirements for planning purposes, although this is modified when the demand requirements change. The estimated demand for a particular unit for the period January through September is given in Table Q3(a). The current workforce is based on the production level in the previous December Operating data are given in Table Q3(b). Requirement: Develop an aggregate plan AP based on level capacity strategy specified for the planning period. Subcontract to meet a 100% service level every month and no overtime, no hiring and no termination. Show graphically the demand forecast, actual production output, and ending inventory in single graph. Determine the total production cost for the specified period. [7] m) Table Q3(c) shows the demand orders of aircraft component of a local customer from January to September. Develop a master planning schedule MPS, assuming production lot size of 800 units, and beginning inventory intended for the particular customer is 150 units. In your MPS indicate the projected available balance PAB and the MPS per month. [3] TableQ3(a): Veatch Company Estimated demand for a product Mar May July August Sep 1,935 2,000 2.250 2,125 2,450 2,700 2,250 1 900 1,650 Jan Feb April June Table Q3(b): Veatch Company Operating data itema Amount Initial inventory (units) 400 125 30 70 85 Stockout costs (OMR unit) Carrying cost (OMR unit month Hiring cost per unit (OMR unit) Termination cost per unit (OMR unit) Subcontract cost (OMR unit) Production units the previous December In-house production cost, (OMR unit) Labor hours/ unit 85 1,500 75 3.2 Workweek (hours) 40 Weeks/month 4 Table Q3(c): Veatch Company Operating data Mar April May June Jan Feb July August Sep 400 450 450 550 600 650 700 750 800 (b) Salalah Electro-Mechanical Company manufactures a product POR 345. The product PQR345 consists of two PQ800 assemblies, three QR432 assemblies and one PR678 assembly. The PQ890 assembly consists of one P456, two Q921 and one 0239. The QR432 assembly consists of three P456, one R478 and two S590 Prepare a Bill of Material (BOM) product tree for the product PQR345. [2] @ Using Table Q3(b)-1 and Table Q3(b)-2 complete the Material Requirements Planning (MRP) calculations to determine when the Purchase Orders should be placed for item S590. Note: The product PQR345 are being sold complete as well as the spare parts (eg. items QR432. PQ890, R478 etc) are being sold separately also. 14 10 14 Table Q3b)-1 12 120 Week PQR345 QR432 16 11 50 13 60 250 70 100 90 15 100 150 40 100 Table Q3(b)-2 Item Lead Time (Weeka) On Hand Batch Size Safety Stock PQR345 QR432 3590 1 2 2 200 200 700 200 300 600 0 150 350Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock