Question: please identify the decision variables, objective function and constraints of the problem Gasoline-Blending Problem of Hexxon Oil Co. Another example of the use of a

please identify the decision variables, objective function and constraints of the problem

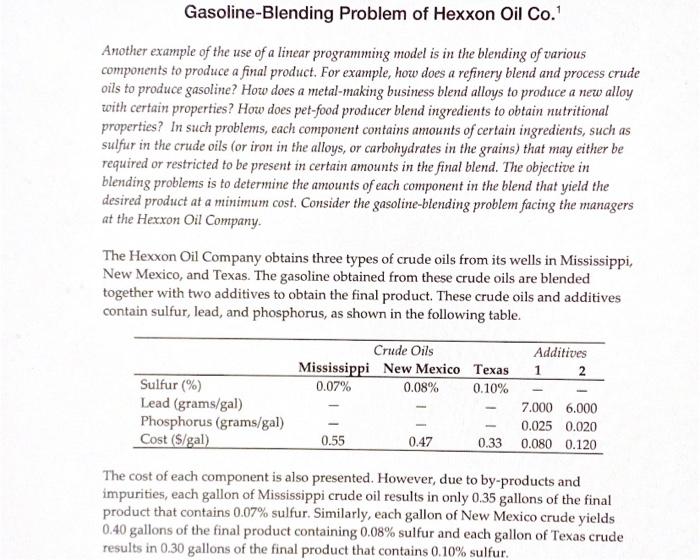

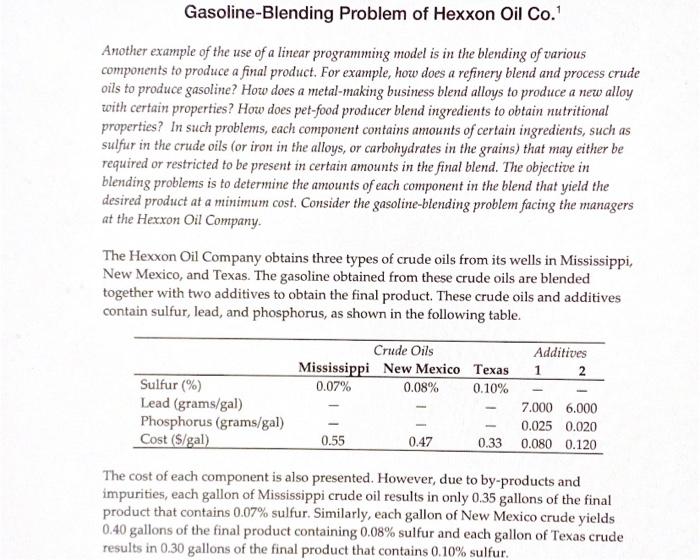

Gasoline-Blending Problem of Hexxon Oil Co. Another example of the use of a linear programming model is in the blending of various components to produce a final product. For example, how does a refinery blend and process crude oils to produce gasoline? How does a metal-making business blend alloys to produce a new alloy with certain properties? How does pet-food producer blend ingredients to obtain nutritional properties? In such problems, each component contains amounts of certain ingredients, such as sulfur in the crude oils (or iron in the alloys, or carbohydrates in the grains) that may either be required or restricted to be present in certain amounts in the final blend. The objective in blending problems is to determine the amounts of each component in the blend that yield the desired product at a minimum cost. Consider the gasoline-blending problem facing the managers at the Hexxon Oil Company The Hexxon Oil Company obtains three types of crude oils from its wells in Mississippi, New Mexico, and Texas. The gasoline obtained from these crude oils are blended together with two additives to obtain the final product. These crude oils and additives contain sulfur, lead, and phosphorus, as shown in the following table. Sulfur (%) Lead (grams/gal) Phosphorus (grams/gal) Cost (S/gal) Crude Oils Additives Mississippi New Mexico Texas 1 2 0.07% 0.08% 0.10% 7.000 6.000 0.025 0.020 0.55 0.47 0.33 0.080 0.120 The cost of each component is also presented. However, due to by-products and impurities, each gallon of Mississippi crude oil results in only 0.35 gallons of the final product that contains 0.07% sulfur. Similarly, each gallon of New Mexico crude yields 0.40 gallons of the final product containing 0.08% sulfur and each gallon of Texas crude results in 0.30 gallons of the final product that contains 0.10% sulfur. Since the blend contains sulfur, lead, and phosphorus, each gallon of the resulting gasoline must meet the following specifications: 1. At most 0.07% sulfur. 2. Between 1.25 and 2.5 grams of lead per gallon 3. Between 0.0025 and 0.0045 grams of phosphorus per gallon. 4. The total amount of the additives cannot exceed 19% of the blend. As Production Manager, determine a blending plan that yields an acceptable gasoline at the least cost. Identify the decision variables, objective function, and constraints of this decision problem. Gasoline-Blending Problem of Hexxon Oil Co. Another example of the use of a linear programming model is in the blending of various components to produce a final product. For example, how does a refinery blend and process crude oils to produce gasoline? How does a metal-making business blend alloys to produce a new alloy with certain properties? How does pet-food producer blend ingredients to obtain nutritional properties? In such problems, each component contains amounts of certain ingredients, such as sulfur in the crude oils (or iron in the alloys, or carbohydrates in the grains) that may either be required or restricted to be present in certain amounts in the final blend. The objective in blending problems is to determine the amounts of each component in the blend that yield the desired product at a minimum cost. Consider the gasoline-blending problem facing the managers at the Hexxon Oil Company The Hexxon Oil Company obtains three types of crude oils from its wells in Mississippi, New Mexico, and Texas. The gasoline obtained from these crude oils are blended together with two additives to obtain the final product. These crude oils and additives contain sulfur, lead, and phosphorus, as shown in the following table. Sulfur (%) Lead (grams/gal) Phosphorus (grams/gal) Cost (S/gal) Crude Oils Additives Mississippi New Mexico Texas 1 2 0.07% 0.08% 0.10% 7.000 6.000 0.025 0.020 0.55 0.47 0.33 0.080 0.120 The cost of each component is also presented. However, due to by-products and impurities, each gallon of Mississippi crude oil results in only 0.35 gallons of the final product that contains 0.07% sulfur. Similarly, each gallon of New Mexico crude yields 0.40 gallons of the final product containing 0.08% sulfur and each gallon of Texas crude results in 0.30 gallons of the final product that contains 0.10% sulfur. Since the blend contains sulfur, lead, and phosphorus, each gallon of the resulting gasoline must meet the following specifications: 1. At most 0.07% sulfur. 2. Between 1.25 and 2.5 grams of lead per gallon 3. Between 0.0025 and 0.0045 grams of phosphorus per gallon. 4. The total amount of the additives cannot exceed 19% of the blend. As Production Manager, determine a blending plan that yields an acceptable gasoline at the least cost. Identify the decision variables, objective function, and constraints of this decision

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock