Question: Please Identify the key problems, and analyze them in detail. In 1960, Bill Dowling, a machine-tool set-up-man for a large auto firm, became so frus-

Please Identify the key problems, and analyze them in detail.

Please Identify the key problems, and analyze them in detail.

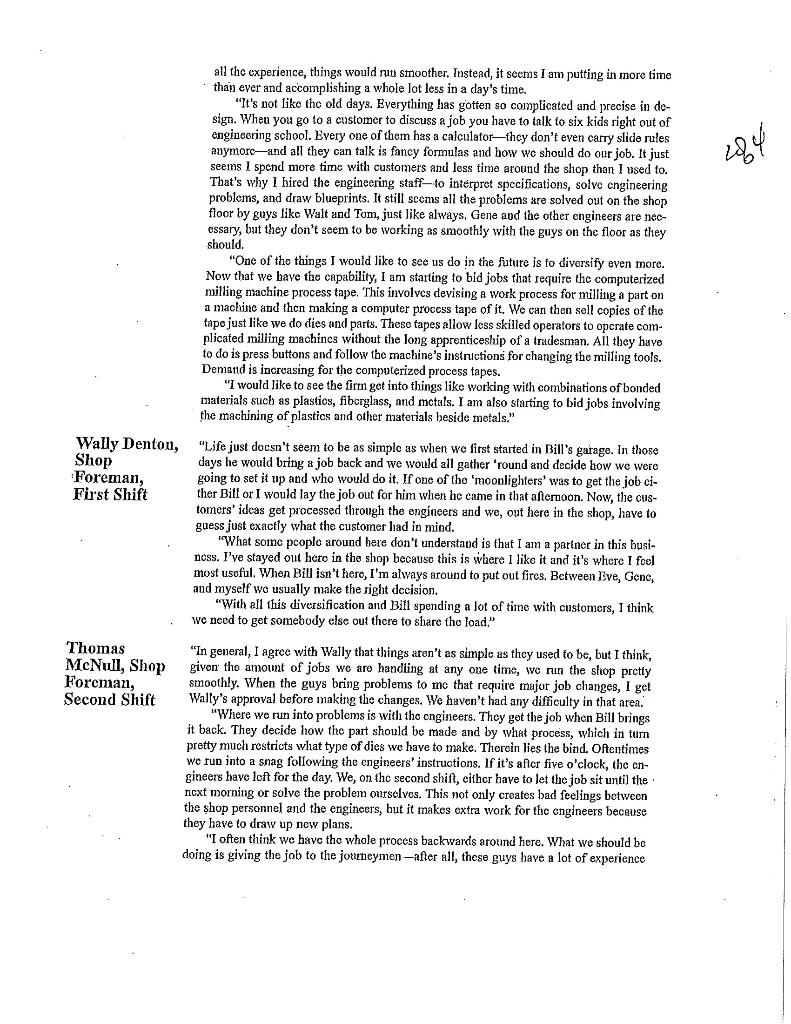

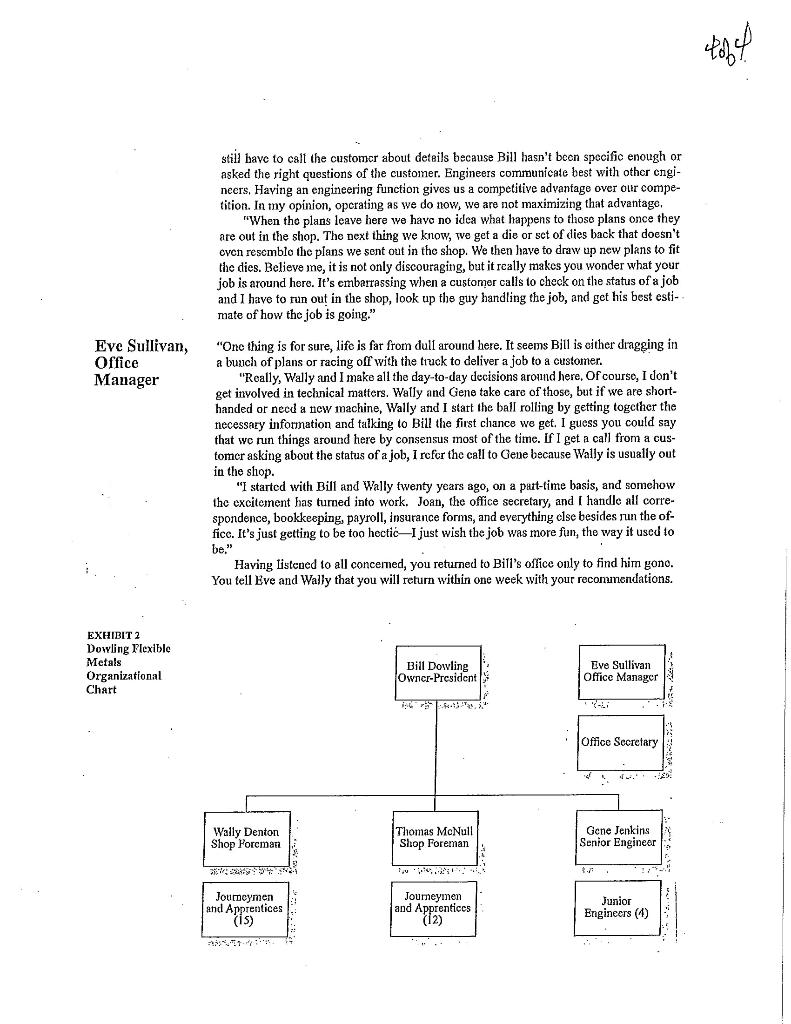

In 1960, Bill Dowling, a "machine-tool set-up-man" for a large auto firm, became so frus- trated with his job that he quit to form his own business. The manufacturing operation consisted of a few general purpose metal working machines that were set up in Dowling's garage. Space was such a constraint that it controlled the work process. For examplo, if the cutting press was to be used with long stock, the milling machines would haye to be pushed back against the wall and remain idle. Production always increased on rain-free, summer days since the garage doors could be opened and a couple of machines moved out onto the drive. Besides Dowling, who acted as salesman, accountant, engineer, president, manufacturing representative, and working foreman, members of the oniginal orgatization were Eve Sullivan, who began as a part-time secretary and payroll elerk; and Wally Denton, who left the auto firm with Bill. The wotkforce was composed of part-time "moonlighters," full-time machinists for other firms, who were attracted by the job au" tonomy which provided experience in setting up jobs and job processes, where a high degree of ingenuity was required. The first years were touch and go with profits being erratic. Giradually tle firm began to gain a reputation for being ingenious at solving uniquo problems and for producing a quality product on, or before, deadlines. The "product" consisted of fabricating dies for making minor component metal parts for automobiles and a specified quantity of the parts. Having realized that the firm was too dependent on the auto industry and that sadden fluctuations in auto sales could have a drastic effect on the firm's survival, Dowling began marketing fheir services toward manufacturing firms not connected with the auto industry. Bids were sabmiffed for work that involved legs for vending machines, metal trim for large appliances, clamps and latches for metal windows, and display racks for small power hand tools. As Dowling Flexible Metals became more diversified, fhe need for expansion forced the company to borrow building funds from the local bank, which enabled construction of a small factory on the edge of town. As new markets and products created a need for increasingly more versatile equipment and a larger workforce, the plant has since expanded twice until it is now three times its original size. In 1980, Dowling Flexible Metals hardly resembles the garage operation of the formative years. The firm now employs approximately thirly full-time journeymen and apprentice machinists, a staff of four engineers that were hired about three years ago, and a full-time office secretary subordinato to Eve Sullivan, the Ofice Manager. Their rapid growth has created problems that in 1980 haye not been resolved. Bill Dowling, realizing his firm is suffcring from growing pains, has askod you to "take a look at the operation and make recommendations as to how things conld be run better." You begin the consulting project by interviewing Dowling, other key people in the firm, and workers out in the shop who seem willing to express their opinions about the firm. Bill Dowling, "We sure have come a long way from that first set-up in my garage. On a nice day we OWner' would get everything all spread out in the drive and then it would slart pouring cats and President dogs -so we would have to move back inside. It was just like a one-ring circus. Now it sesms like a three-ring circus. You would think that with all that talent we haye here and - "Is case was prepared by Floyd G. Wiloughby, Oakland University, Rochester, MI. 01980 by Floyd G. Wifloughby. Reprinted by pernlsslon. Buller, P.F., \& Schuler, R. S. (2003). Managing organizations and people: Cases in management. Toronto: Thomson Nelson. Pp. 105108. all the experience, things would nuth smoother. Instend, it seems I am putting in more time than ever and accomplishing a whole Jot less in a day's time. "It's not like the old days. Everything has gotten so complicated and precise in design. When you go to a customer to discuss a job you have to talk to six kids right out of engineering school. Every one of them has a calculator-thcy don't even carry slide rules anymore-and all they can talk is fancy formulas and how we should do our job. It just seems I spend more time with customers and less time around the shop than I used to. That's why 1 hired the engineering staff-to interpret specifications, solve engineering problems, and draw blueprints. It still seems all the problems are solved out on the shop floor by guys like Walt and Tom, just like always, Gene aod the other engineers are necossary, bat they don't seem to be working as smoothly with the guys on the floor as they should. "One of the things I would like to see us do in the futute is to diversify even more. Now that we have the capability, I am starting to bid jobs that require the computerized milling machine process tape. This involves devising a work process for milling a part on a machine and then making a computer process tape of it. We can then sell copies of the tape just like we do dies and parts. These tapes allow less skilled operators to opcrate complicated milling machincs without the long apprenticeship of a tradesman. All they have to do is press buttons and follow the machine's structions for changing the milling tools. Demand is increasing for the computerized process tapes. "I would like to see the firm get into things like working with combinations of bonded materials such as plastics, fibcrglass, and metals. I am also sfarting to bid jobs involving the machining of plastics and other materials beside metals." "Life just docsn't seem to be as simple as when we first started in IBill's gatage. In those days he would bring a job back and we would all gather 'round and decide how we were going to set it up and who would do it. If one of the 'moonlighters' was to get the job either Bilf or I would lay the job out for him when he came in that afternoon. Now, the customers' ideas get processed through the engineers and we, out here in the shop, have to guess just exactly what the customer lad in mind. "What some pcoplo around bere don't understand is that I am a pariner in this business. I've stayed out here in the shop becauso this is where I like it and it's where I foel most useful. When Bill isn't here, I'm always around to put out fires. Between Bve, Gene, and myself wo usually make the sight dccision. "With all this diversification and Bill spending a lot of time with customers, I think we need to get somebody else ouf there to share tho load." "In general, I agree with Wally that things aten't as simple as they used to be, but I think, given the amount of jobs we are handling at any one time, we nun the shop pretty smoothly. When the guys bring problems to me that require major job changes, I get Wally's approval before making the changes. We haven't had any difficulty in that area. "Where we run into problems is with the engineers. They got the job when Bill brings it back. They decide how the part should be made and by what process, which in tum pretty much restricts what type of dies we have to make. Therein lies the bitid. Oftentimes we run into a snag following the engineers' instructions. If it's affer five o'clock, the engineers have loft for the day. We, on the second shift, either have to let the job sit until the . noxt morning or solve the problem ourselves. This not only creates bad feelings between the shop personnel and the engineers, but it makes extra work for the cngineers because they have to draw up now plans. "I often think we have the whole process backwards around here. What we should be doing is giving the job to the journeymen -after all, these guys have a lot of experience and know-how-then give the finished product to the engineers to draw up. I'll give you an example. Last year we got a job from a vending machine manufacturer. The job consisted of fabricating five seis of dies for making those stubby little legs for vending machines, plus five hundred of the finished legs. Woll, the eugineers figured the job all out, drew up the plans, and sent it out to us. WQ made the first die to specs, but when we tried to punch out the leg on the press, the metal tore. We took the problem back to the engineers, and after the preliminary accusations of who was responsible for the screw up, they changed the raw material specifications. We waited two weeks for delivery of the new steel, then ttied again. The metal still tore. Finally, after two months of hassle, Charlie Oakes and 1 worked on the die for two days and finally came up with a solution. The problem was that the shoulders of the die were too steep for forming the leg in just one punch. We had to use two punches (see Exhibit 1). The problem was the production process, not the raw materials. We spent four months on that job and ran over our deatline. Things like that shouldn't happen." "Really, I hate to say anything against this place because it is a pretty good place to work. The pay and benefits are pretty good and because it is a small shop our hours can be sotnewhat flexible. If you have a doctor's appointment you can either come in late or stay until you get your time in or punch out and come back. You can work as much overtime as you want to. "The thing I'm kind of disappointed about is that I thought the work would be more challenging. I'm just an apprentice, but I've only got a year to go in my program before I can get my journcyman's card, and I think I should be handling more jobs on my own. That's why I came to work hero. My Dad was one of the original 'moonlighters' here. He told me about how interesting it was when he was hero. I guess 1 just expected the samo thing." "I iraagine the guys out in the shop already have told you about 'The Great Vending Machine Fiasco.' 'They'll never let us forget that. However, it does point out the need for botter coordination around here. 'The cngineers were hired as engineers, not as draftsmen, which is just about all we do. I'm not saying we should have the final say on how the job is designed, because there is a lot of practical experience out in that shop; but just as wo haven't their expertise neither do they have ours. 'There is a need for both, the technical skill of the engineers and the practical experience of the shop. "One thing that would really help is more information from Bill. I realizo Bill is spread pretty thin but there are a lot of times he comes back with a job, briefs us, and we still have to call the customar about details because Bill hasn't been specific enough or asked the right questions of the customer. Engineers communicate best with other cngineers, Having an engineering function gives us a competitive advantage over our competition. In my opinion, operating as we do now, we are not maximizing that advantage, "When the plans leave here we havo no idea what happens to those plans once they are out in the shop. The next thing we know, we get a die or set of dies back that doesn't even resemblo the plans we sent out in the shop. We then have to drav up new plans to fit the dies. Believe me, it is not only discouraging, but it really makes you wonder what your job is around here. It's embarrassing when a customer calls to check on the status of a job and I have to run out in the shop, look up the guy handling the job, and get his best estimate of how the job is going." "One thing is for sure, life is far from dull around here. It seems Bill is cither dragging in a bunch of plans or racing off with the truck to deliver a job to a customer. "Really, Wally and I make all the day-to-day decisions aroind here, Of course, I don't get involved in technical matters. Wally and Gene take care of those, but if we are shorthanded or need a new machine, Wally and I statt the ball rolling by getting together the necessary information and talking to Bill the first chance we get. I guess you could say that we nun things around here by consensus most of the time. If I get a call from a customer asking about the status of a job, I rofor the call to Cene because Wally is usually out in the shop. "I started with Bill and Wally fwenty years ago, on a part-time basis, and somehow the excitement has turned into work. Joat, the office secretary, and I handle all correspondence, bookkeeping, payroll, insurance forms, and everything clse besides run the office. It's just getting to be too hectic-I just wish the job was more fun, the way it used to be." Having listened to all concemed, you returned to Bill's oflice only to find him gono. You tell Eve and Wally that you will return within one week with your recommendations

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock