Question: PLEASE MAKE SURE TO ANSWER PART B AND INCLUDE LOT SIZING, LEAD TIME, AND SAFETY STOCK FOR EACH TABLE!!!! I. (50 points) MRP: Resource Planning

PLEASE MAKE SURE TO ANSWER PART B AND INCLUDE LOT SIZING, LEAD TIME, AND SAFETY STOCK FOR EACH TABLE!!!!

PLEASE MAKE SURE TO ANSWER PART B AND INCLUDE LOT SIZING, LEAD TIME, AND SAFETY STOCK FOR EACH TABLE!!!!

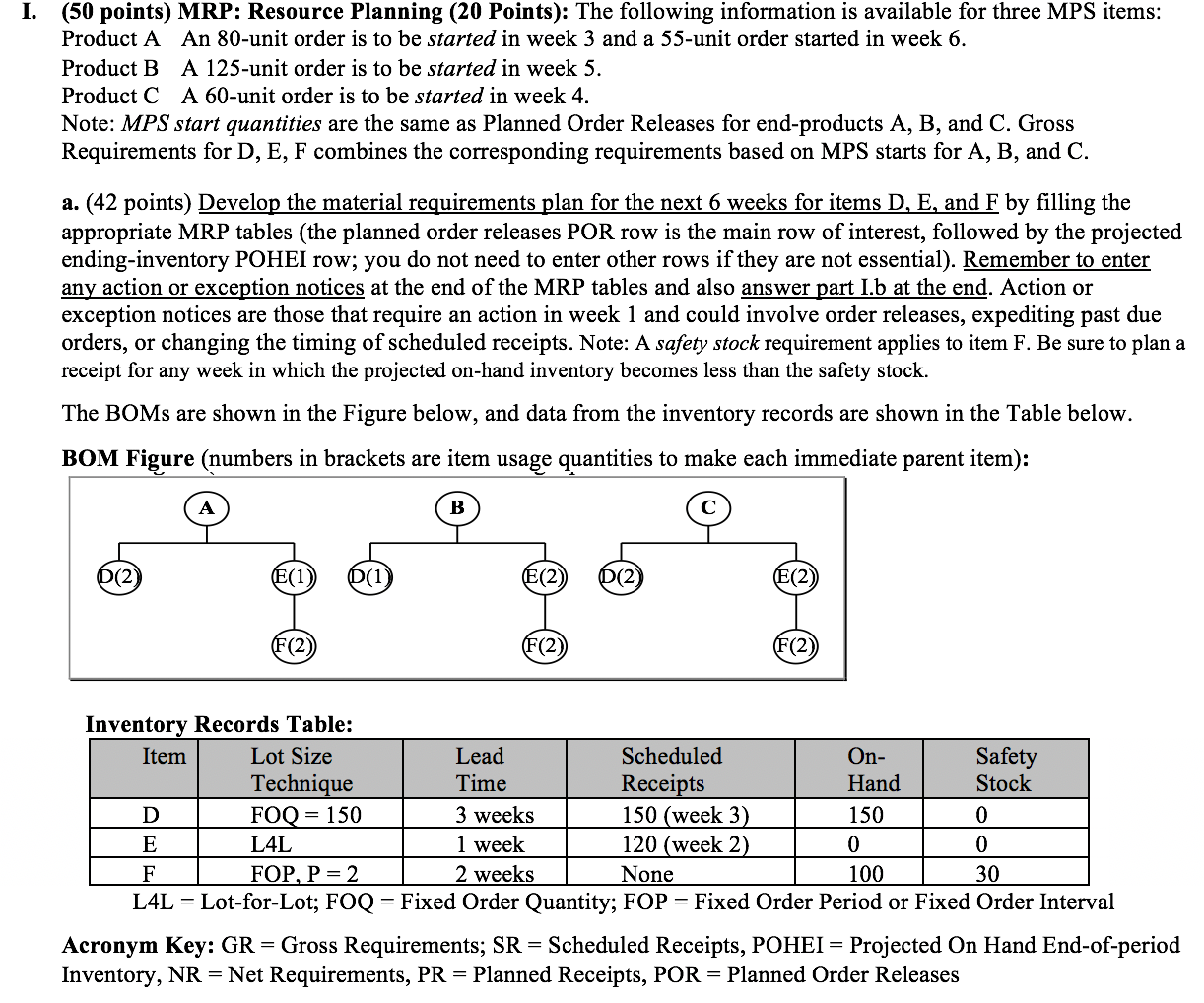

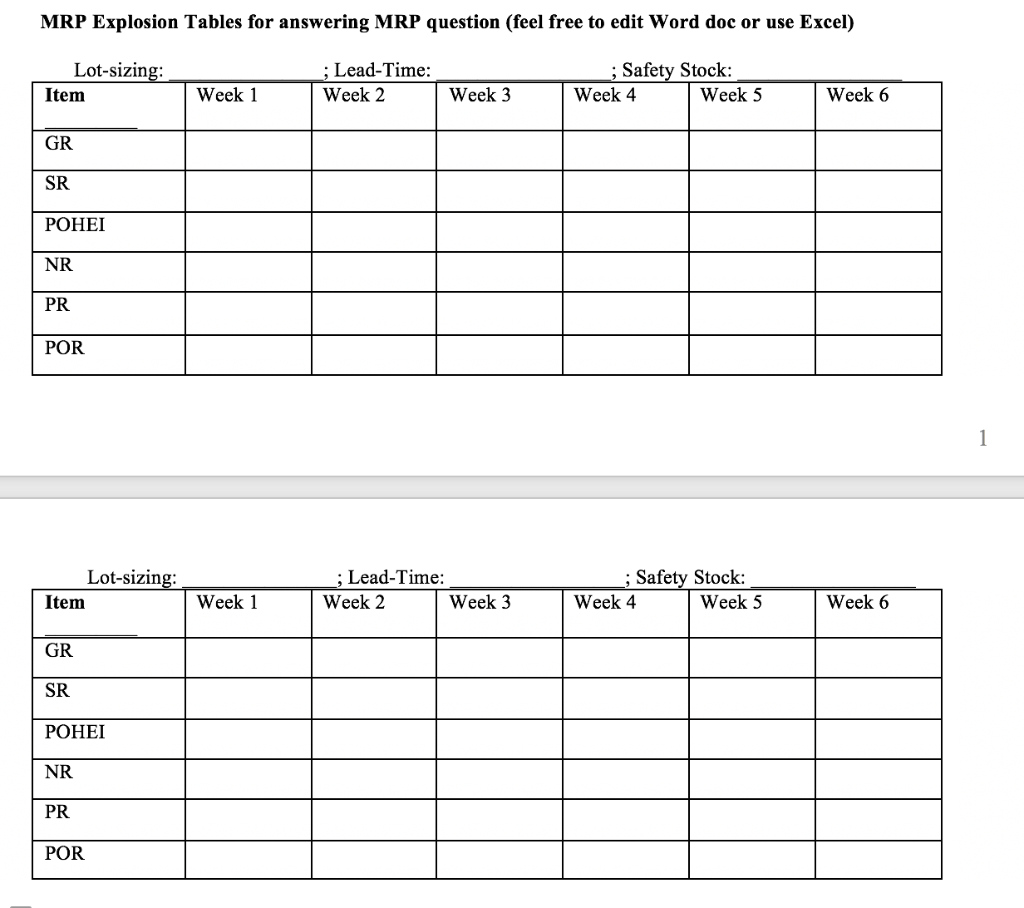

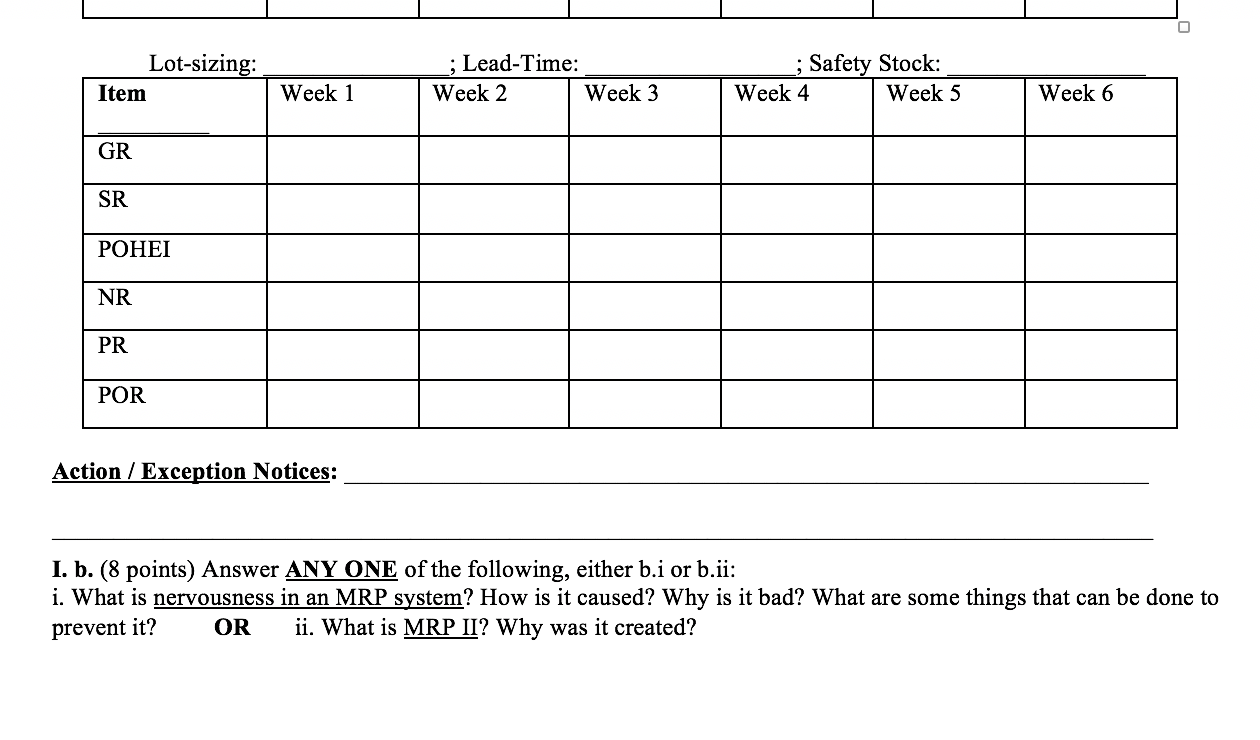

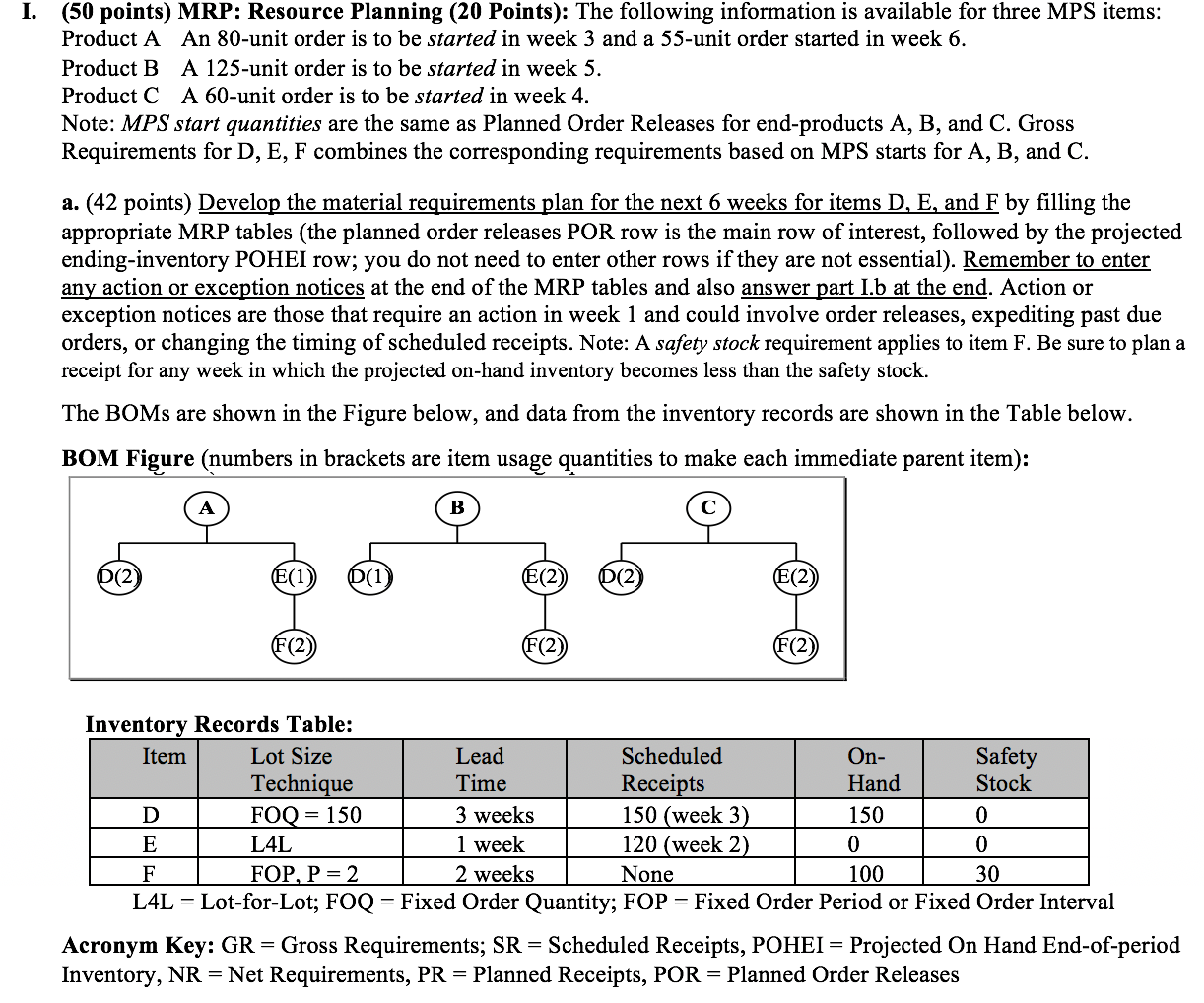

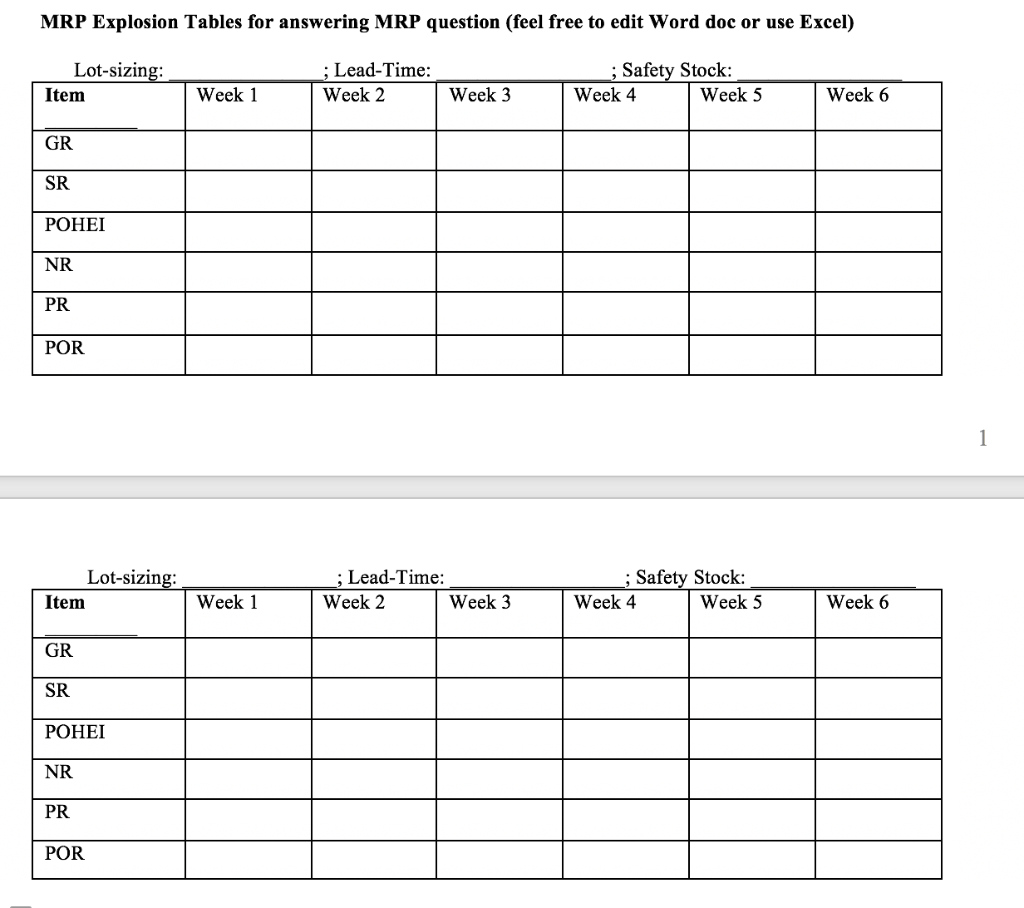

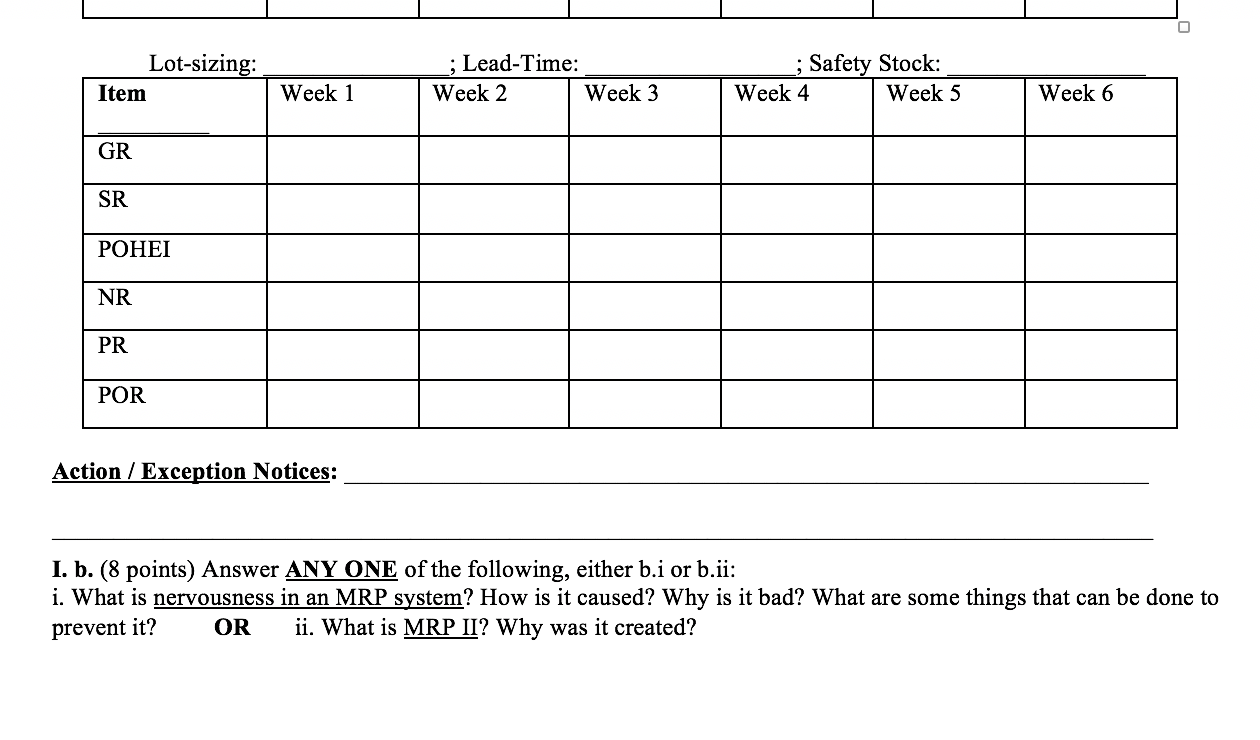

I. (50 points) MRP: Resource Planning (20 Points): The following information is available for three MPS items: Product A An 80-unit order is to be started in week 3 and a 55-unit order started in week 6. Product B A 125-unit order is to be started in week 5. Product CA 60-unit order is to be started in week 4. Note: MPS start quantities are the same as Planned Order Releases for end-products A, B, and C. Gross Requirements for D, E, F combines the corresponding requirements based on MPS starts for A, B, and C. a. (42 points) Develop the material requirements plan for the next 6 weeks for items D, E, and F by filling the appropriate MRP tables (the planned order releases POR row is the main row of interest, followed by the projected ending-inventory POHEI row; you do not need to enter other rows if they are not essential). Remember to enter any action or exception notices at the end of the MRP tables and also answer part I.b at the end. Action or exception notices are those that require an action in week 1 and could involve order releases, expediting past due orders, or changing the timing of scheduled receipts. Note: A safety stock requirement applies to item F. Be sure to plan a receipt for any week in which the projected on-hand inventory becomes less than the safety stock. The BOMs are shown in the Figure below, and data from the inventory records are shown in the Table below. BOM Figure (numbers in brackets are item usage quantities to make each immediate parent item): B D(2 E(1 D(1 E(2) D(2 E(2) F(2) (F(2) F(2) Inventory Records Table: Item Lot Size Lead Scheduled On- Safety Technique Time Receipts Hand Stock D FOQ = 150 3 weeks 150 (week 3) 150 0 E L4L 1 week 120 (week 2) 0 0 F FOP, P=2 2 weeks None 100 30 L4L = Lot-for-Lot; FOQ = Fixed Order Quantity; FOP = Fixed Order Period or Fixed Order Interval Acronym Key: GR = Gross Requirements; SR = Scheduled Receipts, POHEI = Projected On Hand End-of-period Inventory, NR = Net Requirements, PR = Planned Receipts, POR = Planned Order Releases MRP Explosion Tables for answering MRP question (feel free to edit Word doc or use Excel) Lot-sizing: Item ; Lead-Time: Week 2 ; Safety Stock: Week 4 Week 5 Week 1 Week 3 Week 6 GR SR POHEI NR PR POR 1 Lot-sizing: Item ; Lead-Time: Week 2 Week 3 Week 1 _; Safety Stock: Week 4 Week 5 Week 6 GR SR POHEI NR PR POR O Lot-sizing: Item ; Lead-Time: Week 2 Week 3 ; Safety Stock: Week 4 Week 5 Week 1 Week 6 GR SR POHEI NR PR POR Action / Exception Notices: I. b. (8 points) Answer ANY ONE of the following, either b.i or b.ii: i. What is nervousness in an MRP system? How is it caused? Why is it bad? What are some things that can be done to prevent it? OR ii. What is MRP II? Why was it created

PLEASE MAKE SURE TO ANSWER PART B AND INCLUDE LOT SIZING, LEAD TIME, AND SAFETY STOCK FOR EACH TABLE!!!!

PLEASE MAKE SURE TO ANSWER PART B AND INCLUDE LOT SIZING, LEAD TIME, AND SAFETY STOCK FOR EACH TABLE!!!!