Question: Please need a solution by hand and not by spreadsheet. I repeat ONLY BY HAND BMW car manufacturer have to decide between making the piston

Please need a solution by hand and not by spreadsheet. I repeat ONLY BY HAND

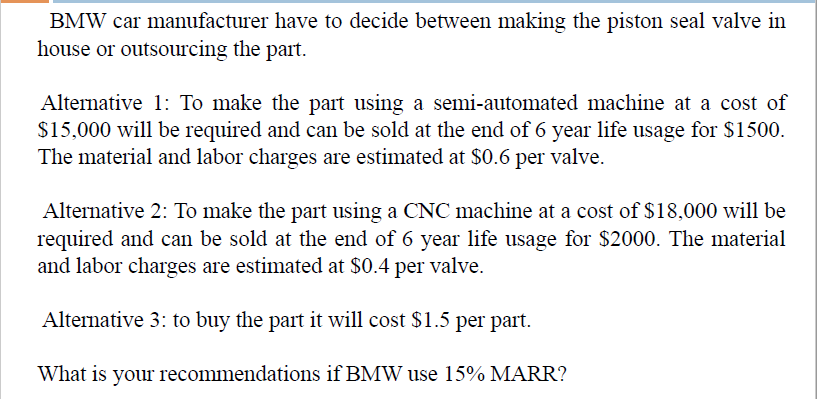

BMW car manufacturer have to decide between making the piston seal valve in house or outsourcing the part. Alternative 1: To make the part using a semi-automated machine at a cost of $15,000 will be required and can be sold at the end of 6 year life usage for $1500. The material and labor charges are estimated at $0.6 per valve. Alternative 2: To make the part using a CNC machine at a cost of $18,000 will be required and can be sold at the end of 6 year life usage for $2000. The material and labor charges are estimated at S0.4 per valve. Alternative 3: to buy the part it will cost $1.5 per part. What is your recommendations if BMW use 15% MARR

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts