Question: Please post a different style answer than the one already solved. (the solution that has been revolving around each other's question) Straight Arrow Steam Beer

Please post a different style answer than the one already solved. (the solution that has been revolving around each other's question)

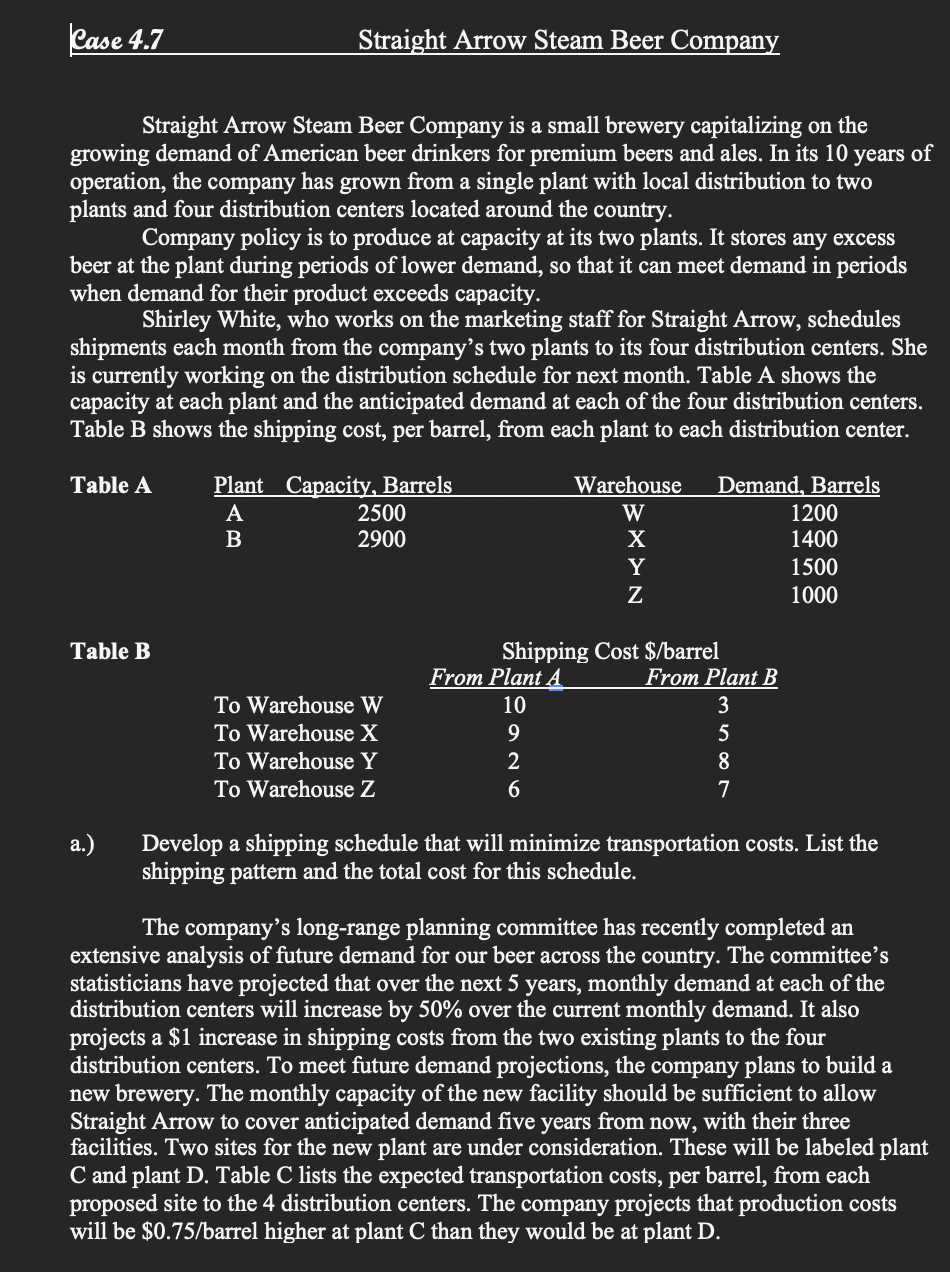

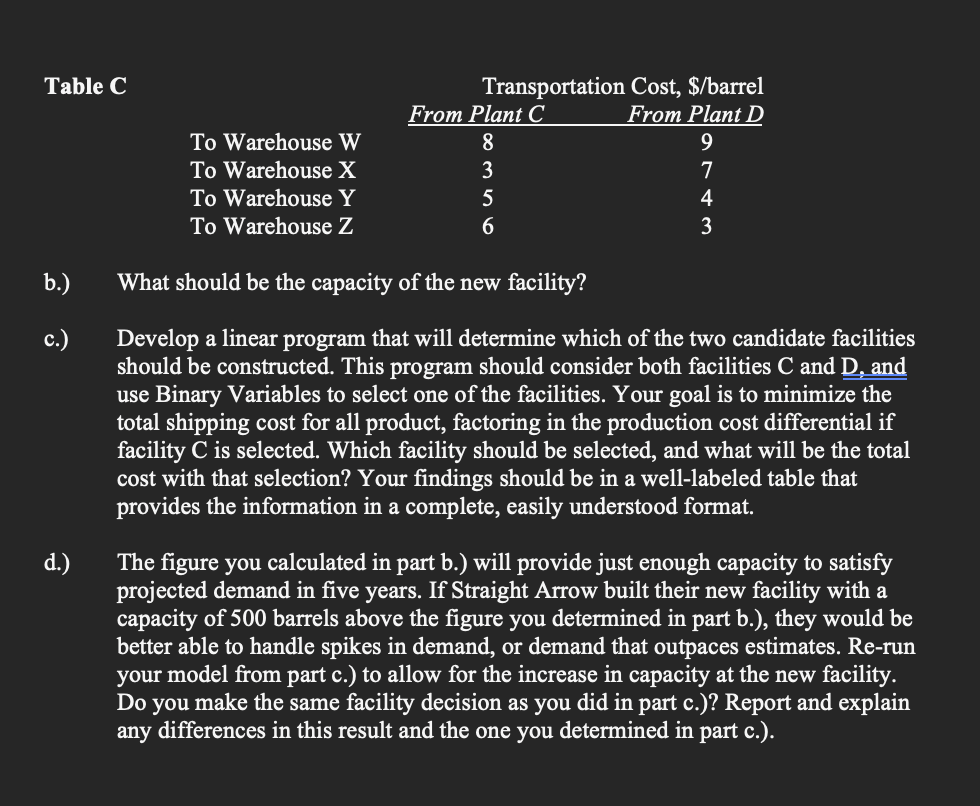

Straight Arrow Steam Beer Company is a small brewery capitalizing on the growing demand of American beer drinkers for premium beers and ales. In its 10 years of operation, the company has grown from a single plant with local distribution to two plants and four distribution centers located around the country. Company policy is to produce at capacity at its two plants. It stores any excess beer at the plant during periods of lower demand, so that it can meet demand in periods when demand for their product exceeds capacity. Shirley White, who works on the marketing staff for Straight Arrow, schedules shipments each month from the company's two plants to its four distribution centers. She is currently working on the distribution schedule for next month. Table A shows the capacity at each plant and the anticipated demand at each of the four distribution centers. Table B shows the shipping cost, per barrel, from each plant to each distribution center. Table Table a.) Develop a shipping schedule that will minimize transportation costs. List the shipping pattern and the total cost for this schedule. The company's long-range planning committee has recently completed an extensive analysis of future demand for our beer across the country. The committee's statisticians have projected that over the next 5 years, monthly demand at each of the distribution centers will increase by 50% over the current monthly demand. It also projects a $1 increase in shipping costs from the two existing plants to the four distribution centers. To meet future demand projections, the company plans to build a new brewery. The monthly capacity of the new facility should be sufficient to allow Straight Arrow to cover anticipated demand five years from now, with their three facilities. Two sites for the new plant are under consideration. These will be labeled plant C and plant D. Table C lists the expected transportation costs, per barrel, from each proposed site to the 4 distribution centers. The company projects that production costs will be $0.75/ barrel higher at plant C than they would be at plant D. able C Transportation Cost, \$/barrel ToWarehouseWToWarehouseXToWarehouseYToWarehouseZFromPlantC8356FromPlantD9743 What should be the capacity of the new facility? Develop a linear program that will determine which of the two candidate facilities should be constructed. This program should consider both facilities C and D,and use Binary Variables to select one of the facilities. Your goal is to minimize the total shipping cost for all product, factoring in the production cost differential if facility C is selected. Which facility should be selected, and what will be the total cost with that selection? Your findings should be in a well-labeled table that provides the information in a complete, easily understood format. The figure you calculated in part b.) will provide just enough capacity to satisfy projected demand in five years. If Straight Arrow built their new facility with a capacity of 500 barrels above the figure you determined in part b.), they would be better able to handle spikes in demand, or demand that outpaces estimates. Re-run your model from part c.) to allow for the increase in capacity at the new facility. Do you make the same facility decision as you did in part c.)? Report and explain any differences in this result and the one you determined in part c.). Straight Arrow Steam Beer Company is a small brewery capitalizing on the growing demand of American beer drinkers for premium beers and ales. In its 10 years of operation, the company has grown from a single plant with local distribution to two plants and four distribution centers located around the country. Company policy is to produce at capacity at its two plants. It stores any excess beer at the plant during periods of lower demand, so that it can meet demand in periods when demand for their product exceeds capacity. Shirley White, who works on the marketing staff for Straight Arrow, schedules shipments each month from the company's two plants to its four distribution centers. She is currently working on the distribution schedule for next month. Table A shows the capacity at each plant and the anticipated demand at each of the four distribution centers. Table B shows the shipping cost, per barrel, from each plant to each distribution center. Table Table a.) Develop a shipping schedule that will minimize transportation costs. List the shipping pattern and the total cost for this schedule. The company's long-range planning committee has recently completed an extensive analysis of future demand for our beer across the country. The committee's statisticians have projected that over the next 5 years, monthly demand at each of the distribution centers will increase by 50% over the current monthly demand. It also projects a $1 increase in shipping costs from the two existing plants to the four distribution centers. To meet future demand projections, the company plans to build a new brewery. The monthly capacity of the new facility should be sufficient to allow Straight Arrow to cover anticipated demand five years from now, with their three facilities. Two sites for the new plant are under consideration. These will be labeled plant C and plant D. Table C lists the expected transportation costs, per barrel, from each proposed site to the 4 distribution centers. The company projects that production costs will be $0.75/ barrel higher at plant C than they would be at plant D. able C Transportation Cost, \$/barrel ToWarehouseWToWarehouseXToWarehouseYToWarehouseZFromPlantC8356FromPlantD9743 What should be the capacity of the new facility? Develop a linear program that will determine which of the two candidate facilities should be constructed. This program should consider both facilities C and D,and use Binary Variables to select one of the facilities. Your goal is to minimize the total shipping cost for all product, factoring in the production cost differential if facility C is selected. Which facility should be selected, and what will be the total cost with that selection? Your findings should be in a well-labeled table that provides the information in a complete, easily understood format. The figure you calculated in part b.) will provide just enough capacity to satisfy projected demand in five years. If Straight Arrow built their new facility with a capacity of 500 barrels above the figure you determined in part b.), they would be better able to handle spikes in demand, or demand that outpaces estimates. Re-run your model from part c.) to allow for the increase in capacity at the new facility. Do you make the same facility decision as you did in part c.)? Report and explain any differences in this result and the one you determined in part c.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts