Question: Please send the solution in excel describing the steps. This is an excel assignment We want to maximize the profits from manufacturing steel tables. Each

Please send the solution in excel describing the steps. This is an excel assignment

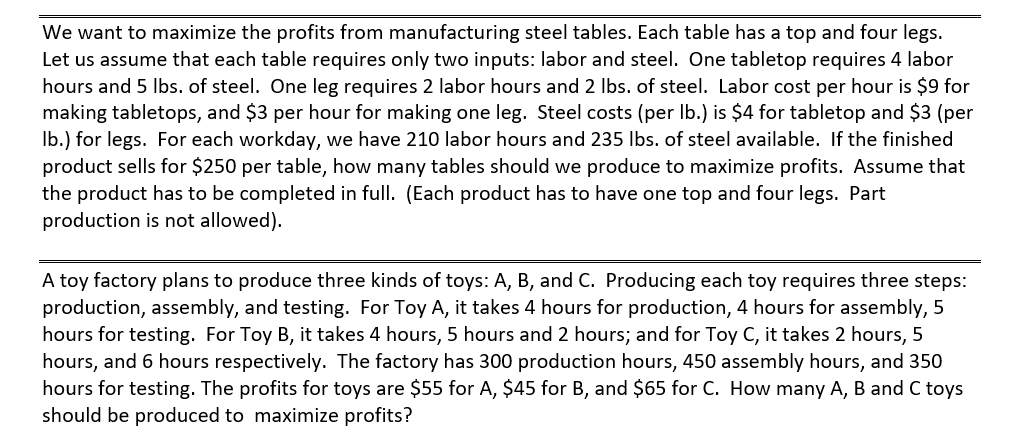

We want to maximize the profits from manufacturing steel tables. Each table has a top and four legs. Let us assume that each table requires only two inputs: labor and steel. One tabletop requires 4 labor hours and 5 lbs. of steel. One leg requires 2 labor hours and 2 lbs. of steel. Labor cost per hour is $9 for making tabletops, and $3 per hour for making one leg. Steel costs (per lb.) is $4 for tabletop and $3 (per Ib.) for legs. For each workday, we have 210 labor hours and 235 lbs. of steel available. If the finished product sells for $250 per table, how many tables should we produce to maximize profits. Assume that the product has to be completed in full. (Each product has to have one top and four legs. Part production is not allowed). A toy factory plans to produce three kinds of toys: A, B, and C. Producing each toy requires three steps: production, assembly, and testing. For Toy A, it takes 4 hours for production, 4 hours for assembly, 5 hours for testing. For Toy B, it takes 4 hours, 5 hours and 2 hours; and for Toy C, it takes 2 hours, 5 hours, and 6 hours respectively. The factory has 300 production hours, 450 assembly hours, and 350 hours for testing. The profits for toys are $55 for A, $45 for B, and $65 for C. How many A, B and C toys should be produced to maximize profitsStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock