Question: please show all the work and process 1. Consider the following three cases for binary distillation of a mixture of two components, A and B.

please show all the work and process

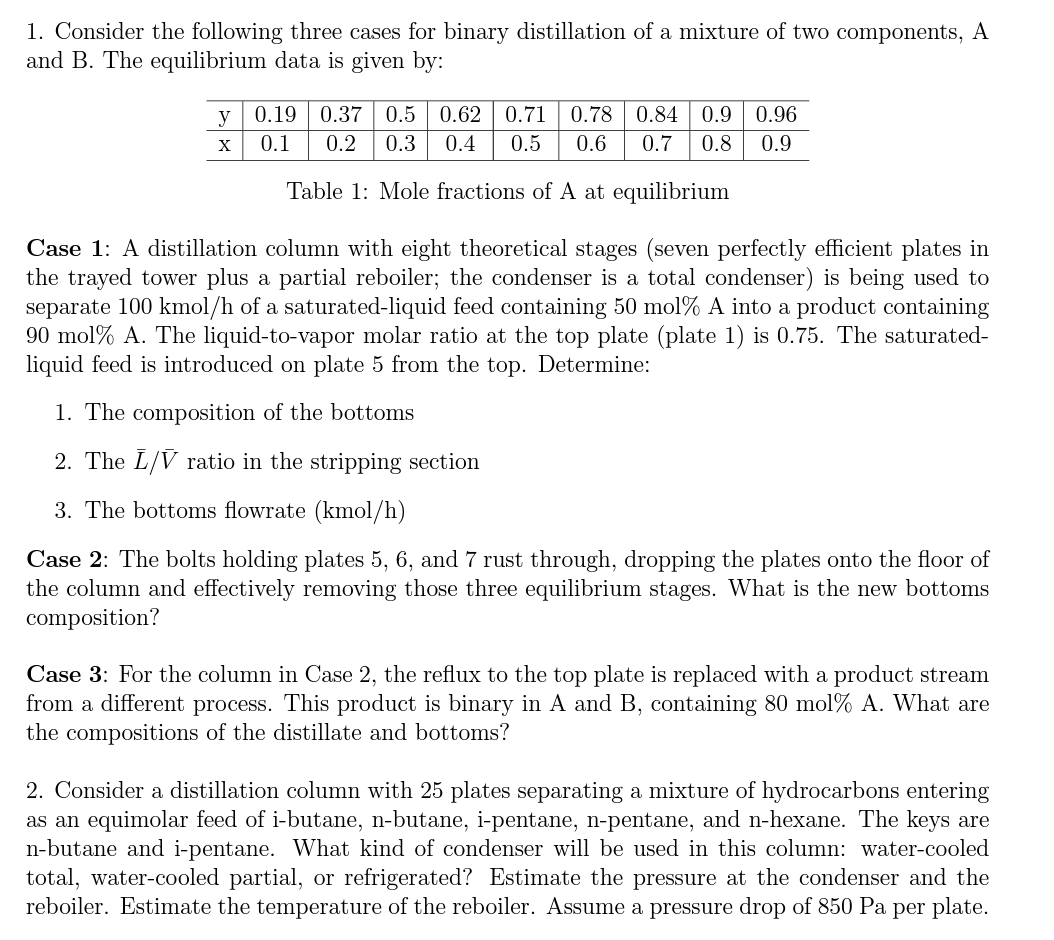

1. Consider the following three cases for binary distillation of a mixture of two components, A and B. The equilibrium data is given by: Table 1: Mole fractions of A at equilibrium Case 1: A distillation column with eight theoretical stages (seven perfectly efficient plates in the trayed tower plus a partial reboiler; the condenser is a total condenser) is being used to separate 100kmol/h of a saturated-liquid feed containing 50mol% A into a product containing 90mol%A. The liquid-to-vapor molar ratio at the top plate (plate 1) is 0.75 . The saturatedliquid feed is introduced on plate 5 from the top. Determine: 1. The composition of the bottoms 2. The L/V ratio in the stripping section 3. The bottoms flowrate (kmol/h) Case 2: The bolts holding plates 5, 6, and 7 rust through, dropping the plates onto the floor of the column and effectively removing those three equilibrium stages. What is the new bottoms composition? Case 3: For the column in Case 2, the reflux to the top plate is replaced with a product stream from a different process. This product is binary in A and B, containing 80mol%A. What are the compositions of the distillate and bottoms? 2. Consider a distillation column with 25 plates separating a mixture of hydrocarbons entering as an equimolar feed of i-butane, n-butane, i-pentane, n-pentane, and n-hexane. The keys are n-butane and i-pentane. What kind of condenser will be used in this column: water-cooled total, water-cooled partial, or refrigerated? Estimate the pressure at the condenser and the reboiler. Estimate the temperature of the reboiler. Assume a pressure drop of 850 Pa per plate

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts