Question: please show calculations! :) this is the entire question 1. In the factory represented below, strict discipline insures that operations only work on items scheduled

please show calculations! :)

this is the entire question

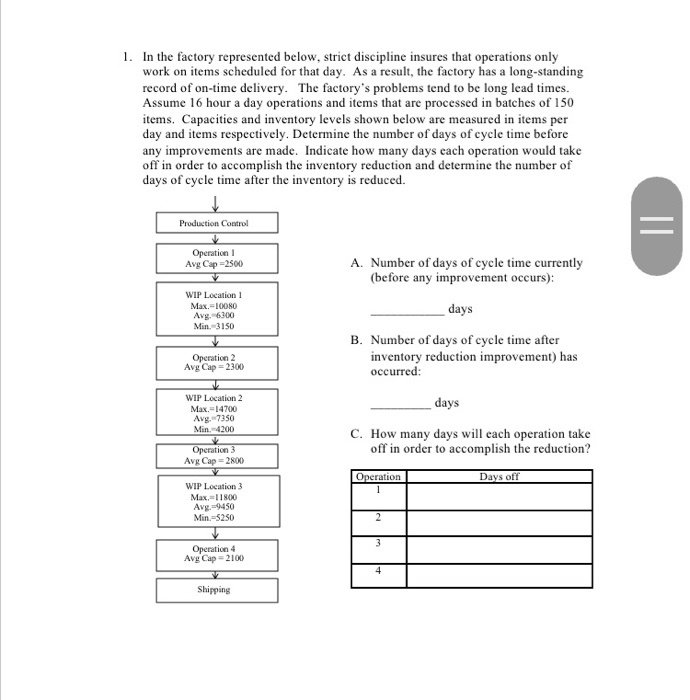

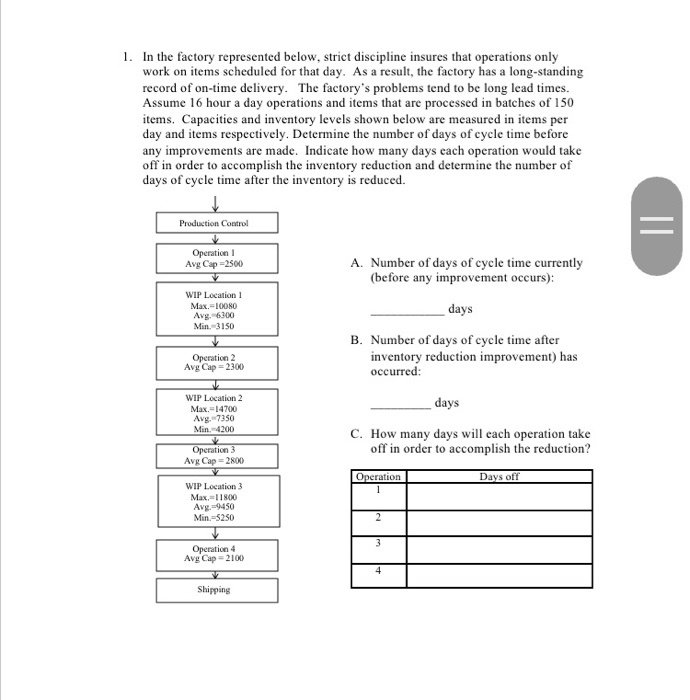

1. In the factory represented below, strict discipline insures that operations only work on items scheduled for that day. As a result, the factory has a long-standing record of on-time delivery. The factory's problems tend to be long lead times. Assume 16 hour a day operations and items that are processed in batches of 150 items. Capacities and inventory levels shown below are measured in items per day and items respectively. Determine the number of days of cycle time before any improvements are made. Indicate how many days each operation would take off in order to accomplish the inventory reduction and determine the number of days of cycle time after the inventory is reduced. Production Control Operation Avg Cap=2500 A. Number of days of cycle time currently (before any improvement occurs): WIP Location ! Max=10080 Avg. 6300 Min.-3150 days Operation 2 Avg Cap=2300 B. Number of days of cycle time after inventory reduction improvement) has occurred: days WIP Location 2 Max -14700 Avg. 7350 Min. 4200 C. How many days will each operation take off in order to accomplish the reduction? Operation 3 Avg Cap 2800 Operation Days off WIP Location 3 Max, 18.00 Avg. 9450 Min.-5250 Operation 4 Avg Cap 2100 Shipping 1. In the factory represented below, strict discipline insures that operations only work on items scheduled for that day. As a result, the factory has a long-standing record of on-time delivery. The factory's problems tend to be long lead times. Assume 16 hour a day operations and items that are processed in batches of 150 items. Capacities and inventory levels shown below are measured in items per day and items respectively. Determine the number of days of cycle time before any improvements are made. Indicate how many days each operation would take off in order to accomplish the inventory reduction and determine the number of days of cycle time after the inventory is reduced. Production Control Operation Avg Cap=2500 A. Number of days of cycle time currently (before any improvement occurs): WIP Location ! Max=10080 Avg. 6300 Min.-3150 days Operation 2 Avg Cap=2300 B. Number of days of cycle time after inventory reduction improvement) has occurred: days WIP Location 2 Max -14700 Avg. 7350 Min. 4200 C. How many days will each operation take off in order to accomplish the reduction? Operation 3 Avg Cap 2800 Operation Days off WIP Location 3 Max, 18.00 Avg. 9450 Min.-5250 Operation 4 Avg Cap 2100 Shipping Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock