Question: please show the calculation clearly , if there is excel show it too thanks 1 A smart phone maker in Singapore, ABC produces a variety

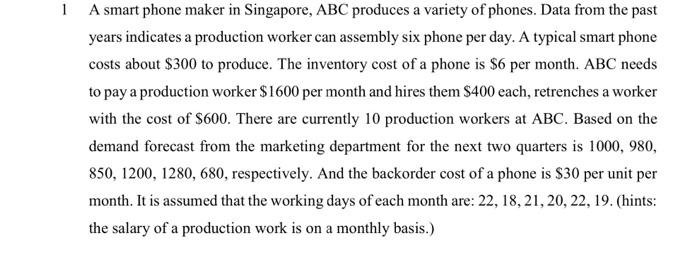

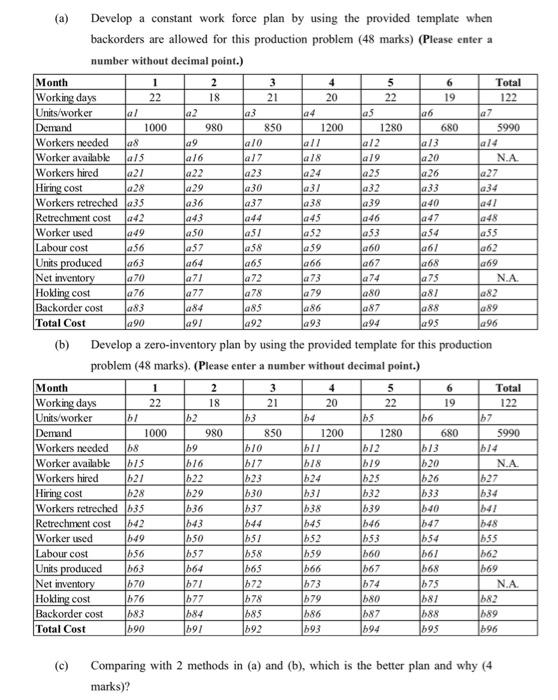

1 A smart phone maker in Singapore, ABC produces a variety of phones. Data from the past years indicates a production worker can assembly six phone per day. A typical smart phone costs about $300 to produce. The inventory cost of a phone is $6 per month. ABC needs to pay a production worker $1600 per month and hires them $400 each, retrenches a worker with the cost of $600. There are currently 10 production workers at ABC. Based on the demand forecast from the marketing department for the next two quarters is 1000, 980, 850, 1200, 1280, 680, respectively. And the backorder cost of a phone is $30 per unit per month. It is assumed that the working days of each month are: 22, 18, 21, 20, 22, 19.(hints: the salary of a production work is on a monthly basis.) 429 1434 Develop a constant work force plan by using the provided template when backorders are allowed for this production problem (48 marks) (Please enter a number without decimal point.) Month 1 2 3 4 5 6 Total Working days 22 18 21 20 22 19 122 Units/worker a 2 a3 a4 Jas a6 a7 Demand 1000 980 850 1200 1280 680 5990 Workers needed a8 Jag a10 Jal/ a12 a/3 a14 Worker available a/5 a16 a17 al8 a19 a 20 N.A Workers hired a21 a22 423 424 a25 a 26 427 Hiring cost a28 a30 a32 a33 Workers retreched a35 la36 a37 a 38 a 39 a40 441 Retrechment cost a42 a43 a44 a45 a46 a47 a48 Worker used a49 a 50 45/ a32 Ja 33 a54 a35 Labour cost lash a37 a58 a39 |a60 a6/ 262 Units produced a63 a64 a65 1266 |a67 Ja 68 Ja69 Net inventory a 70 471 a72 473 474 |a75 NA Holding cost a 76 a77 a 78 a 79 a80 Ja8/ 082 Backorder cost a83 a84 485 a86 |a87 a88 089 Total Cost |a90 a9/ 492 1993 494 a95 496 (b) Develop a zero-inventory plan by using the provided template for this production problem (48 marks) (Please enter a number without decimal point.) Month 1 2 3 4 5 6 Total Working days 22 18 21 20 22 19 122 Units/worker b1 52 b3 54 b5 16 157 Demand 1000 980 850 1200 1280 680 5990 Workers needed 58 59 510 511 512 513 514 Worker available bis 516 b17 b18 b19 520 NA Workers hired 521 522 b23 524 525 526 527 Hiring cost b28 b29 b30 b3/ b32 533 534 Workers retreched 635 b36 637 b38 |b39 1540 141 Retrechment cost 542 543 544 545 546 547 548 Worker used 549 550 551 b52 553 554 555 Labour cost 556 b57 b58 559 560 561 562 Units produced 163 564 1665 b66 |567 568 569 Net inventory 570 b71 672 573 1574 N.A Holding cost 576 b77 678 679 1580 1581 b82 Backorder cost 583 584 b85 586 1587 588 189 Total Cost 090 69/ 692 693 1594 695 696 575 (c) Comparing with 2 methods in (a) and (b), which is the better plan and why (4 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts