Question: Please show the steps and formulas for how to complete in Excel. The Strollers-to-Go Company makes lightweight umbrella-type strollers for three different groups of children.

Please show the steps and formulas for how to complete in Excel.

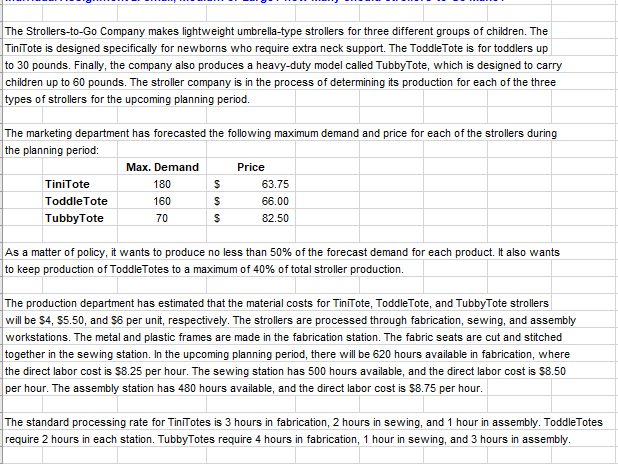

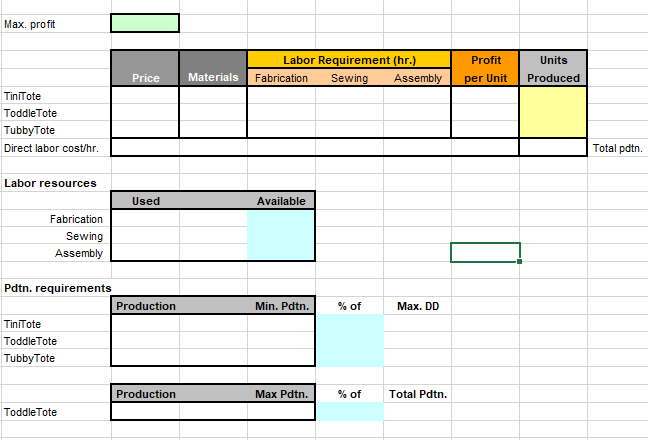

The Strollers-to-Go Company makes lightweight umbrella-type strollers for three different groups of children. The TiniTote is designed specifically for newborns who require extra neck support. The Toddle Tote is for toddlers up to 30 pounds. Finally, the company also produces a heavy-duty model called TubbyTote, which is designed to carry children up to 60 pounds. The stroller company is in the process of determining its production for each of the three types of strollers for the upcoming planning period. The marketing department has forecasted the following maximum demand and price for each of the strollers during the planning period: Max. Demand Price TiniTote 180 $ 63.75 Toddle Tote 160 $ 66.00 Tubby Tote 70 $ 82.50 As a matter of policy, it wants to produce no less than 50% of the forecast demand for each product. It also wants to keep production of Toddle Totes to a maximum of 40% of total stroller production. The production department has estimated that the material costs for Tin Tote, Toddle Tote, and TubbyTote strollers will be 54, 55.50, and 56 per unit, respectively. The strollers are processed through fabrication, sewing, and assembly workstations. The metal and plastic frames are made in the fabrication station. The fabric seats are cut and stitched together in the sewing station. In the upcoming planning period, there will be 620 hours available in fabrication, where the direct labor cost is $8.25 per hour. The sewing station has 500 hours available, and the direct labor cost is $8.50 per hour. The assembly station has 480 hours available, and the direct labor cost is $8.75 per hour. The standard processing rate for TiniTotes is 3 hours in fabrication, 2 hours in sewing, and 1 hour in assembly. ToddleTotes require 2 hours in each station. TubbyTotes require 4 hours in fabrication, 1 hour in sewing, and 3 hours in assembly. Max. profit Profit Labor Requirement (hr.) Fabrication Sewing Assembly Units Produced Price Materials per Unit TiniTote Toddle Tote TubbyTote Direct labor cost/hr. Total pdtn. Labor resources Used Available Fabrication Sewing Assembly Min. Pdtn. % of Max. DD Pdtn. requirements Production TiniTote Toddle Tote TubbyTote Production Max Pdtn. % of Total Pdtn. Toddle ToteStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock