Question: please show the working on this. NOTE: You may receive ZERO marks for this question if you do not submit proof of working out. Keep

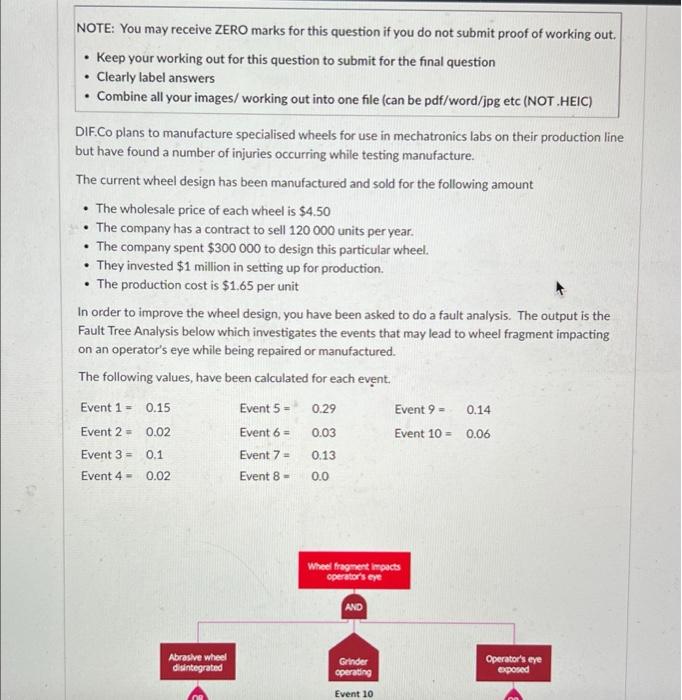

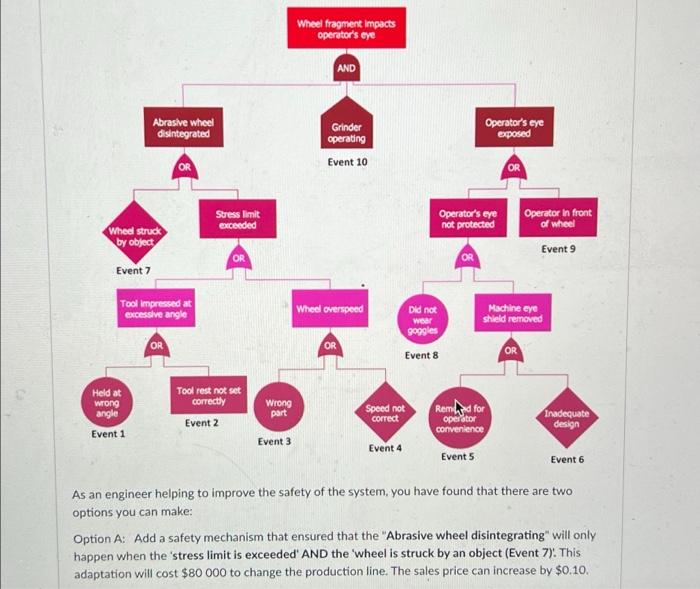

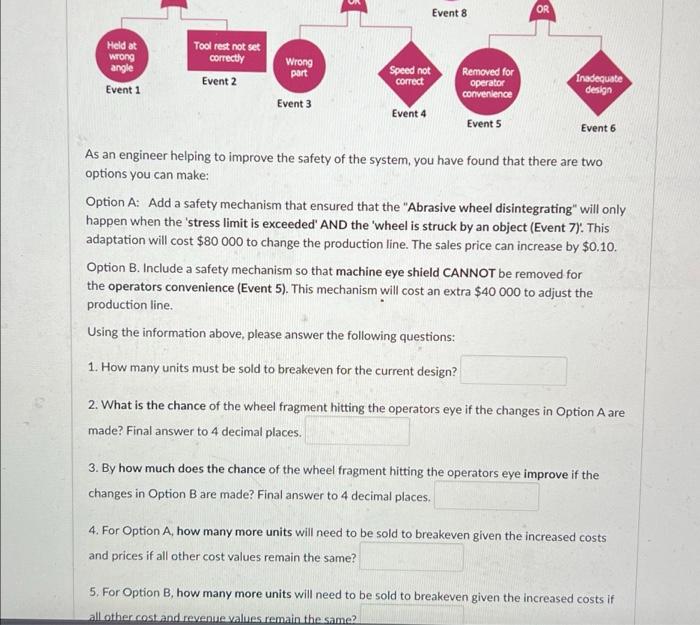

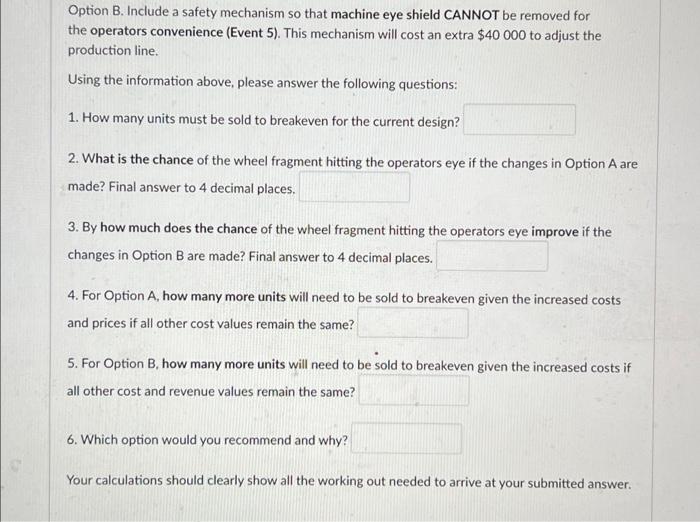

NOTE: You may receive ZERO marks for this question if you do not submit proof of working out. Keep your working out for this question to submit for the final question Clearly label answers . Combine all your images/ working out into one file (can be pdf/word/jpg etc (NOT HEIC) DIF.Co plans to manufacture specialised wheels for use in mechatronics labs on their production line but have found a number of injuries occurring while testing manufacture. The current wheel design has been manufactured and sold for the following amount The wholesale price of each wheel is $4.50 The company has a contract to sell 120 000 units per year. The company spent $300 000 to design this particular wheel. They invested $1 million in setting up for production The production cost is $1.65 per unit In order to improve the wheel design, you have been asked to do a fault analysis. The output is the Fault Tree Analysis below which investigates the events that may lead to wheel fragment impacting on an operator's eye while being repaired or manufactured. The following values, have been calculated for each event. Event 1 - 0.15 Event 5- Event 9 - Event 2 0.02 Event 6 = Event 10 0.06 Event 3 = 0.1 Event 7 0.13 Event 4 = 0.02 Event 8 - 0.29 0.14 0.03 0.0 Wheel fragment impacts operator's eye AND Abrasive wheel disintegrated Operator's eye Grinder operating exposed Event 10 Wheel fragment impacts operator's eye AND Abrasive wheel disintegrated Operator's eye exposed Grinder operating Event 10 OR Stress limit exceeded Operator's eye not protected Operator in front of wheel Wheel struck by object Event 9 OR OR Event 2 Tool impressed at excessive angle Wheel overspeed Did not 1 Machine eye shield removed weer goggles OR OR Event 8 OR Held at wrong angle Tool rest not set correctly Event 2 Wrong part Speed not correct Remd for operator convenience Inadequate design Event 1 Event 3 Event 4 Event 5 Event 6 As an engineer helping to improve the safety of the system, you have found that there are two options you can make: Option A: Add a safety mechanism that ensured that the "Abrasive wheel disintegrating" will only happen when the 'stress limit is exceeded' AND the wheel is struck by an object (Event 7). This adaptation will cost $80 000 to change the production line. The sales price can increase by $0.10. OR Event 8 Held at wrong angle Tool rest not set correctly Event 2 Wrong part Speed not correct Removed for operator convenience Event 1 Inadequate design Event 3 Event 4 Event 5 Event 6 As an engineer helping to improve the safety of the system, you have found that there are two options you can make: Option A: Add a safety mechanism that ensured that the "Abrasive wheel disintegrating will only happen when the 'stress limit is exceeded' AND the 'wheel is struck by an object (Event 7). This adaptation will cost $80 000 to change the production line. The sales price can increase by $0.10. Option B. Include a safety mechanism so that machine eye shield CANNOT be removed for the operators convenience (Event 5). This mechanism will cost an extra $40 000 to adjust the production line. Using the information above, please answer the following questions: 1. How many units must be sold to breakeven for the current design? 2. What is the chance of the wheel fragment hitting the operators eye if the changes in Option A are made? Final answer to 4 decimal places. 3. By how much does the chance of the wheel fragment hitting the operators eye improve if the changes in Option B are made? Final answer to 4 decimal places. 4. For Option A, how many more units will need to be sold to breakeven given the increased costs and prices if all other cost values remain the same? 5. For Option B, how many more units will need to be sold to breakeven given the increased costs if all other cost and revieme values remain the same? a Option B. Include a safety mechanism so that machine eye shield CANNOT be removed for the operators convenience (Event 5). This mechanism will cost an extra $40 000 to adjust the production line. Using the information above, please answer the following questions: 1. How many units must be sold to breakeven for the current design? 2. What is the chance of the wheel fragment hitting the operators eye if the changes in Option A are made? Final answer to 4 decimal places. 3. By how much does the chance of the wheel fragment hitting the operators eye improve if the changes in Option B are made? Final answer to 4 decimal places. 4. For Option A, how many more units will need to be sold to breakeven given the increased costs and prices if all other cost values remain the same? 5. For Option B, how many more units will need to be sold to breakeven given the increased costs if all other cost and revenue values remain the same? 6. Which option would you recommend and why? Your calculations should clearly show all the working out needed to arrive at your submitted answer. NOTE: You may receive ZERO marks for this question if you do not submit proof of working out. Keep your working out for this question to submit for the final question Clearly label answers . Combine all your images/ working out into one file (can be pdf/word/jpg etc (NOT HEIC) DIF.Co plans to manufacture specialised wheels for use in mechatronics labs on their production line but have found a number of injuries occurring while testing manufacture. The current wheel design has been manufactured and sold for the following amount The wholesale price of each wheel is $4.50 The company has a contract to sell 120 000 units per year. The company spent $300 000 to design this particular wheel. They invested $1 million in setting up for production The production cost is $1.65 per unit In order to improve the wheel design, you have been asked to do a fault analysis. The output is the Fault Tree Analysis below which investigates the events that may lead to wheel fragment impacting on an operator's eye while being repaired or manufactured. The following values, have been calculated for each event. Event 1 - 0.15 Event 5- Event 9 - Event 2 0.02 Event 6 = Event 10 0.06 Event 3 = 0.1 Event 7 0.13 Event 4 = 0.02 Event 8 - 0.29 0.14 0.03 0.0 Wheel fragment impacts operator's eye AND Abrasive wheel disintegrated Operator's eye Grinder operating exposed Event 10 Wheel fragment impacts operator's eye AND Abrasive wheel disintegrated Operator's eye exposed Grinder operating Event 10 OR Stress limit exceeded Operator's eye not protected Operator in front of wheel Wheel struck by object Event 9 OR OR Event 2 Tool impressed at excessive angle Wheel overspeed Did not 1 Machine eye shield removed weer goggles OR OR Event 8 OR Held at wrong angle Tool rest not set correctly Event 2 Wrong part Speed not correct Remd for operator convenience Inadequate design Event 1 Event 3 Event 4 Event 5 Event 6 As an engineer helping to improve the safety of the system, you have found that there are two options you can make: Option A: Add a safety mechanism that ensured that the "Abrasive wheel disintegrating" will only happen when the 'stress limit is exceeded' AND the wheel is struck by an object (Event 7). This adaptation will cost $80 000 to change the production line. The sales price can increase by $0.10. OR Event 8 Held at wrong angle Tool rest not set correctly Event 2 Wrong part Speed not correct Removed for operator convenience Event 1 Inadequate design Event 3 Event 4 Event 5 Event 6 As an engineer helping to improve the safety of the system, you have found that there are two options you can make: Option A: Add a safety mechanism that ensured that the "Abrasive wheel disintegrating will only happen when the 'stress limit is exceeded' AND the 'wheel is struck by an object (Event 7). This adaptation will cost $80 000 to change the production line. The sales price can increase by $0.10. Option B. Include a safety mechanism so that machine eye shield CANNOT be removed for the operators convenience (Event 5). This mechanism will cost an extra $40 000 to adjust the production line. Using the information above, please answer the following questions: 1. How many units must be sold to breakeven for the current design? 2. What is the chance of the wheel fragment hitting the operators eye if the changes in Option A are made? Final answer to 4 decimal places. 3. By how much does the chance of the wheel fragment hitting the operators eye improve if the changes in Option B are made? Final answer to 4 decimal places. 4. For Option A, how many more units will need to be sold to breakeven given the increased costs and prices if all other cost values remain the same? 5. For Option B, how many more units will need to be sold to breakeven given the increased costs if all other cost and revieme values remain the same? a Option B. Include a safety mechanism so that machine eye shield CANNOT be removed for the operators convenience (Event 5). This mechanism will cost an extra $40 000 to adjust the production line. Using the information above, please answer the following questions: 1. How many units must be sold to breakeven for the current design? 2. What is the chance of the wheel fragment hitting the operators eye if the changes in Option A are made? Final answer to 4 decimal places. 3. By how much does the chance of the wheel fragment hitting the operators eye improve if the changes in Option B are made? Final answer to 4 decimal places. 4. For Option A, how many more units will need to be sold to breakeven given the increased costs and prices if all other cost values remain the same? 5. For Option B, how many more units will need to be sold to breakeven given the increased costs if all other cost and revenue values remain the same? 6. Which option would you recommend and why? Your calculations should clearly show all the working out needed to arrive at your submitted

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts