Question: Please show work :D Analyze the problem below... A specialized aerospace product is being manufacture in a facility of the company To the Infinity and

Please show work :D

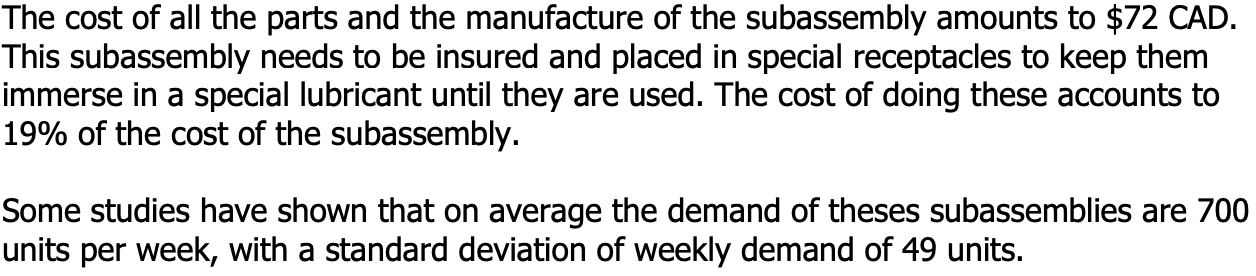

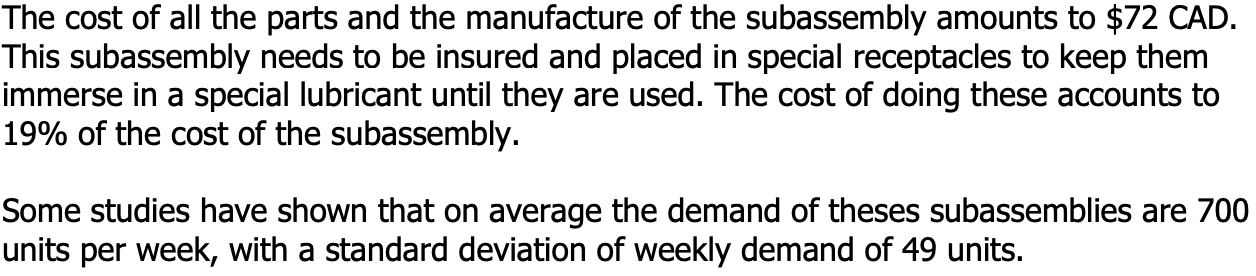

Analyze the problem below... A specialized aerospace product is being manufacture in a facility of the company "To the Infinity and Beyond" (TIB) in Ontario. A subassembly is shipped from Edmonton, AB, and it is very important to have enough inventory of that subassembly, otherwise the final assembly of the product cannot be finished, resulting in significant loses for the company. Based on their calculations, they would like to have this subassembly practically all the time and can only tolerate 1% chances of stocking out of that component. The purchasing team of the company in Edmonton, charges $30 CAD +5% of tax, every time they are required to place an order and send the subassembly to the TIB company. The time that elapses from the moment that the order is place until the product arrives to the warehouse in Ontario is 3 full days. The cost of all the parts and the manufacture of the subassembly amounts to $72 CAD. This subassembly needs to be insured and placed in special receptacles to keep them immerse in a special lubricant until they are used. The cost of doing these accounts to 19% of the cost of the subassembly. Some studies have shown that on average the demand of theses subassemblies are 700 units per week, with a standard deviation of weekly demand of 49 units. 1. Knowing all these facts, if you are hired as a business consultant to minimize the cost of the inventory for this, what information would you provide to the production manager of the company in Ontario? (Hint: Provide ALL the information required by the people in charge of the inventory, including any provisions to maintain the desired cycle service level for the company) 2. After a few years after you provided your advice (and charged the big bucks), the company reach out to you again, but now they are using a different strategy, by placing orders in fixed time intervals. They place orders every 15 days. They hire a new manager to handle the inventory, but they are not too sure that the orders that are being submitted under this new model are 100% correct, and they would like to hire you again to help them identifying if what they will do for their next order is right. The demand is roughly the same, but the variance of the daily demand is 25 units. They also changed the supplier and the time to receive the orders once those are placed, is now two days. You have access at the information about the units of the subassembly that they currently have in the warehouse is 154 , and there are also 28 subassemblies that are on their way arriving tomorrow, as the previous receipt of parts was incomplete. Also, 16 of the subassemblies that are in the warehouse now were received damaged, so those will be sent back right away. Can you make a full analysis to provide the information that they may need to make sure that they submit the right order