Question: Please solve ALL questions and write the letters with the corresponded number. Thank you for the help ASSIGNMENT #2B: INVENTORY MODELS 1) Customers at Joe's

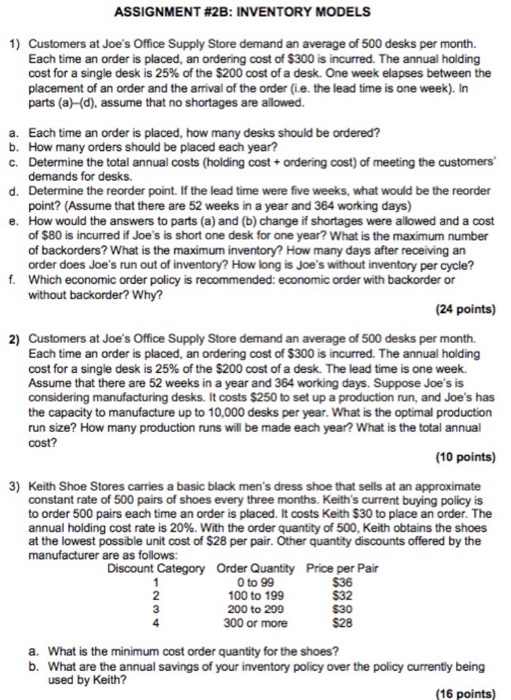

ASSIGNMENT #2B: INVENTORY MODELS 1) Customers at Joe's Office Supply Store demand an average of 500 desks per month. Each time an order is placed, an ordering cost of $300 is incurred. The annual holding cost for a single desk is 25% of the $200 cost of a desk. One week elapses between the placement of an order and the arrival of the order (ie. the lead time is one week). In parts (a) (d), assume that no shortages are allowed. a. Each time an order is placed, how many desks should be ordered? b. How many orders should be placed each year? c. Determine the total annual costs (holding cost+ ordering cost) of meeting the customers demands for desks d. Determine the reorder point. If the lead time were five weeks, what would be the reorder point? (Assume that there are 52 weeks in a year and 364 working days) e. How would the answers to parts (a) and (b) change if shortages were allowed and a cost of $80 is incurred if Joe's is short one desk for one year? What is the maximum number of backorders? What is the maximum inventory? How many days after receiving an order does Joe's run out of inventory? How long is Joe's without inventory per cycle? Which economic order policy is recommended: economic order with backorder or without backorder? Why? f. (24 points) Customers at Joe's Office Supply Store demand an average of 500 desks per month. Each time an order is placed, an ordering cost of $300 is incurred. The annual holding cost for a single desk is 25% of the $200 cost of a desk. The lead time is one week. Assume that there are 52 weeks in a year and 364 working days. Suppose Joe's is considering manufacturing desks. It costs $250 to set up a production run, and Joe's has the capacity to manufacture up to 10,000 desks per year. What is the optimal production run size? How many production runs will be made each year? What is the total annual cost? 2) (10 points) 3) Keith Shoe Stores carries a basic black men's dress shoe that sells at an approximate constant rate of 500 pairs of shoes every three months. Keith's current buying policy is to order 500 pairs each time an order is placed. It costs Keith $30 to place an order. The annual holding cost rate is 20%. With the order quantity of 500, Keith obtains the shoes at the lowest possible unit cost of $28 per pair. Other quantity discounts offered by the manufacturer are as follows: Discount Category Order Quantity Price per Pair 0 to 99 100 to 199 200 to 209 300 or more S32 S30 $28 2 3 a. What is the minimum cost order quantity for the shoes? b. What are the annual savings of your inventory policy over the policy currently being used by Keith? (16 points)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts