Question: Please solve and I will like the answer. Question 1: A planner has developed an aggregate forecast for demand (in cases) for the next six

Please solve and I will like the answer.

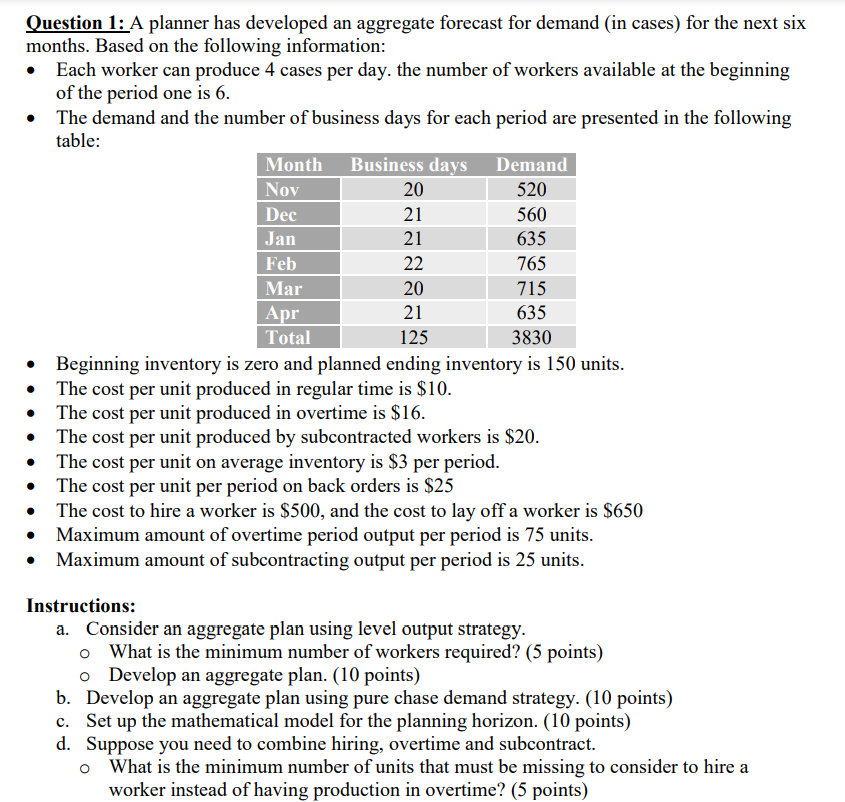

Question 1: A planner has developed an aggregate forecast for demand (in cases) for the next six months. Based on the following information: - Each worker can produce 4 cases per day. the number of workers available at the beginning of the period one is 6 . - The demand and the number of business days for each period are presented in the following table: - Beginning inventory is zero and planned ending inventory is 150 units. - The cost per unit produced in regular time is $10. - The cost per unit produced in overtime is $16. - The cost per unit produced by subcontracted workers is $20. - The cost per unit on average inventory is $3 per period. - The cost per unit per period on back orders is $25 - The cost to hire a worker is $500, and the cost to lay off a worker is $650 - Maximum amount of overtime period output per period is 75 units. - Maximum amount of subcontracting output per period is 25 units. Instructions: a. Consider an aggregate plan using level output strategy. - What is the minimum number of workers required? (5 points) - Develop an aggregate plan. ( 10 points) b. Develop an aggregate plan using pure chase demand strategy. (10 points) c. Set up the mathematical model for the planning horizon. (10 points) d. Suppose you need to combine hiring, overtime and subcontract. - What is the minimum number of units that must be missing to consider to hire a worker instead of having production in overtime? ( 5 points) Question 1: A planner has developed an aggregate forecast for demand (in cases) for the next six months. Based on the following information: - Each worker can produce 4 cases per day. the number of workers available at the beginning of the period one is 6 . - The demand and the number of business days for each period are presented in the following table: - Beginning inventory is zero and planned ending inventory is 150 units. - The cost per unit produced in regular time is $10. - The cost per unit produced in overtime is $16. - The cost per unit produced by subcontracted workers is $20. - The cost per unit on average inventory is $3 per period. - The cost per unit per period on back orders is $25 - The cost to hire a worker is $500, and the cost to lay off a worker is $650 - Maximum amount of overtime period output per period is 75 units. - Maximum amount of subcontracting output per period is 25 units. Instructions: a. Consider an aggregate plan using level output strategy. - What is the minimum number of workers required? (5 points) - Develop an aggregate plan. ( 10 points) b. Develop an aggregate plan using pure chase demand strategy. (10 points) c. Set up the mathematical model for the planning horizon. (10 points) d. Suppose you need to combine hiring, overtime and subcontract. - What is the minimum number of units that must be missing to consider to hire a worker instead of having production in overtime? ( 5 points)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock