Question: Please solve it in a way I can write in my notebook, not on a laptop. 6. Vendor selection One of the major problems in

Please solve it in a way I can write in my notebook, not on a laptop.

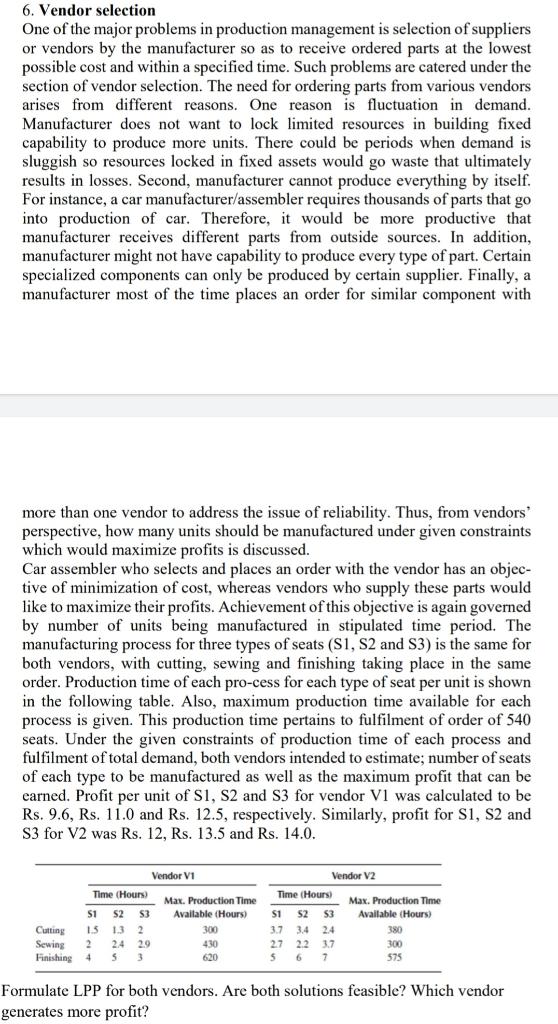

6. Vendor selection One of the major problems in production management is selection of suppliers or vendors by the manufacturer so as to receive ordered parts at the lowest possible cost and within a specified time. Such problems are catered under the section of vendor selection. The need for ordering parts from various vendors arises from different reasons. One reason is fluctuation in demand. Manufacturer does not want to lock limited resources in building fixed capability to produce more units. There could be periods when demand is sluggish so resources locked in fixed assets would go waste that ultimately results in losses. Second, manufacturer cannot produce everything by itself. For instance, a car manufacturer/assembler requires thousands of parts that go into production of car. Therefore, it would be more productive that manufacturer receives different parts from outside sources. In addition, manufacturer might not have capability to produce every type of part. Certain specialized components can only be produced by certain supplier. Finally, a manufacturer most of the time places an order for similar component with more than one vendor to address the issue of reliability. Thus, from vendors' perspective, how many units should be manufactured under given constraints which would maximize profits is discussed. Car assembler who selects and places an order with the vendor has an objective of minimization of cost, whereas vendors who supply these parts would like to maximize their profits. Achievement of this objective is again governed by number of units being manufactured in stipulated time period. The manufacturing process for three types of seats ( S1,S2 and S3 ) is the same for both vendors, with cutting, sewing and finishing taking place in the same order. Production time of each pro-cess for each type of seat per unit is shown in the following table. Also, maximum production time available for each process is given. This production time pertains to fulfilment of order of 540 seats. Under the given constraints of production time of each process and fulfilment of total demand, both vendors intended to estimate; number of seats of each type to be manufactured as well as the maximum profit that can be earned. Profit per unit of S1, S2 and S3 for vendor V1 was calculated to be Rs. 9.6, Rs. 11.0 and Rs. 12.5, respectively. Similarly, profit for S1, S2 and S3 for V2 was Rs. 12, Rs. 13.5 and Rs. 14.0. Formulate LPP for both vendors. Are both solutions feasible? Which vendor generates more profitStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock