Question: please solve it step by step and explain 13) Jackson Sheds has four different warehouse configurations under study, ranging from four warehouses to seven warehouses

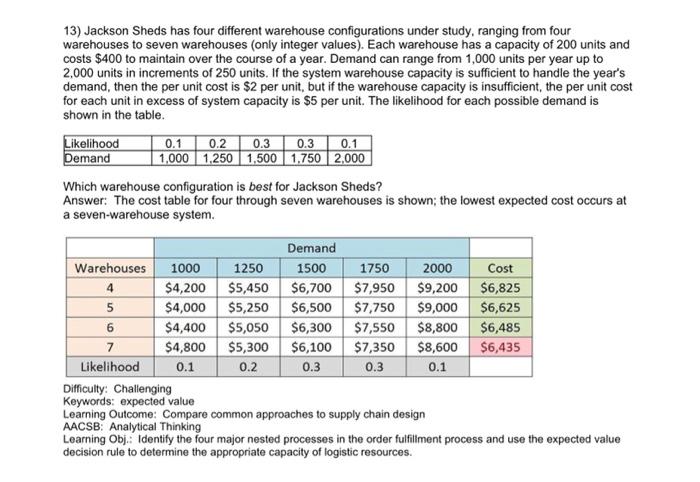

13) Jackson Sheds has four different warehouse configurations under study, ranging from four warehouses to seven warehouses (only integer values). Each warehouse has a capacity of 200 units and costs $400 to maintain over the course of a year. Demand can range from 1,000 units per year up to 2,000 units in increments of 250 units. If the system warehouse capacity is sufficient to handle the year's demand, then the per unit cost is $2 per unit, but if the warehouse capacity is insufficient, the per unit cost for each unit in excess of system capacity is $5 per unit. The likelihood for each possible demand is shown in the table. Which warehouse configuration is best for Jackson Sheds? Answer: The cost table for four through seven warehouses is shown; the lowest expected cost occurs at a seven-warehouse system. Difficulty: Challenging Keywords: expected value Learning Outcome: Compare common approaches to supply chain design AACSB: Analytical Thinking Learning Obj.: Identify the four major nested processes in the order fulfilment process and use the expected value decision rule to determine the appropriate capacity of logistic resources

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts