Question: please solve it with numbers not just the formula Question 2: Imagine yourself taking the role of a maintenance planner. Consider the problem explanation and

please solve it with numbers not just the formula

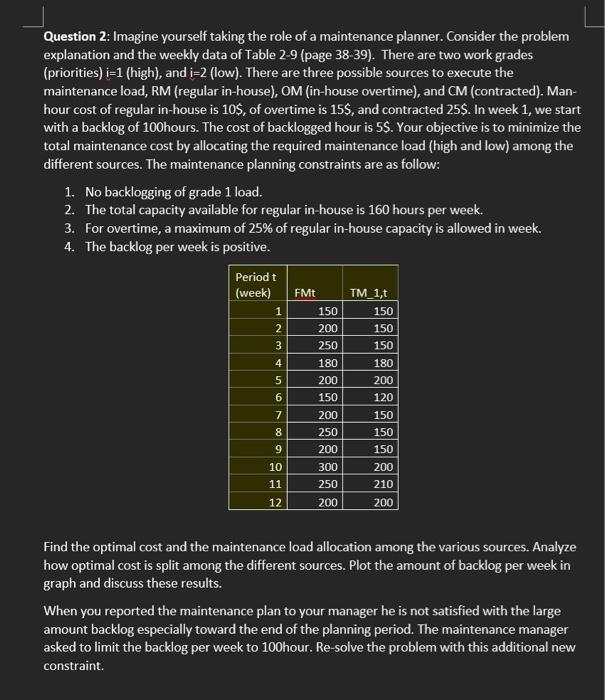

Question 2: Imagine yourself taking the role of a maintenance planner. Consider the problem explanation and the weekly data of Table 2-9 (page 38-39). There are two work grades (priorities) i=1 (high), and i=2 (low). There are three possible sources to execute the maintenance load, RM (regular in-house), OM (in-house overtime), and CM (contracted). Man-hour cost of regular in-house is 10$, of overtime is 15$, and contracted 25$. In week 1, we start with a backlog of 100hours. The cost of backlogged hour is 5$. Your objective is to minimize the total maintenance cost by allocating the required maintenance load (high and low) among the different sources. The maintenance planning constraints are as follow:

1. No backlogging of grade 1 load.

2. The total capacity available for regular in-house is 160 hours per week.

3. For overtime, a maximum of 25% of regular in-house capacity is allowed in week.

4. The backlog per week is positive.

Period t (week) FMt TM_1,t

1 150 150

2 200 150

3 250 150

4 180 180

5 200 200

6 150 120

7 200 150

8 250 150

9 200 150

10 300 200

11 250 210

12 200 200

Find the optimal cost and the maintenance load allocation among the various sources. Analyze how optimal cost is split among the different sources. Plot the amount of backlog per week in graph and discuss these results.

When you reported the maintenance plan to your manager he is not satisfied with the large amount backlog especially toward the end of the planning period. The maintenance manager asked to limit the backlog per week to 100hour. Re-solve the problem with this additional new constraint.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock