Question: please solve please answer (20 marks) Charlie's Cycles is a local manufacturer of specialty bikes. Charlie has always ordered the bike parts in bulk to

please solve

please answer

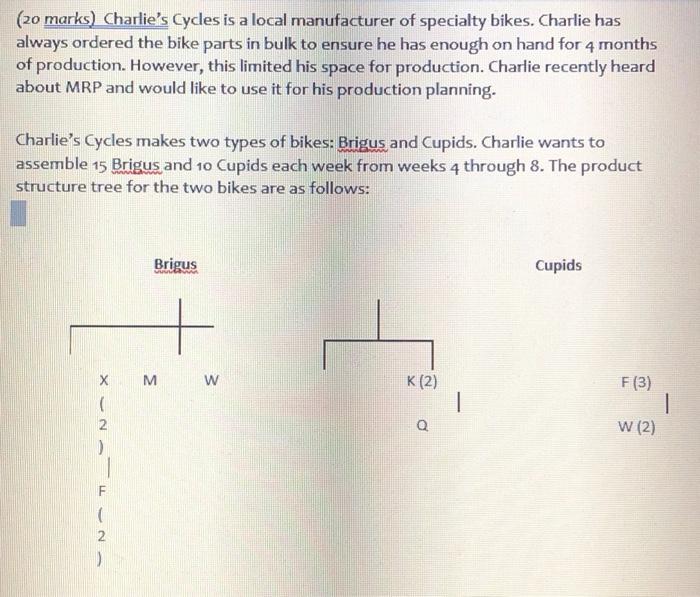

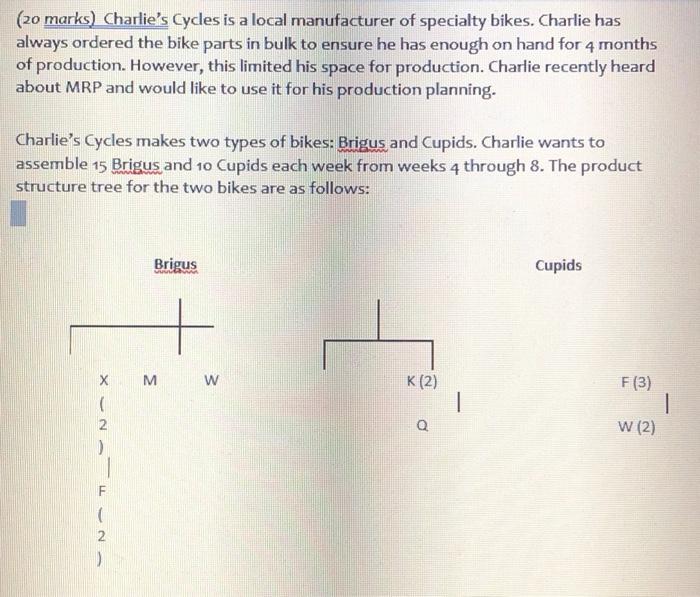

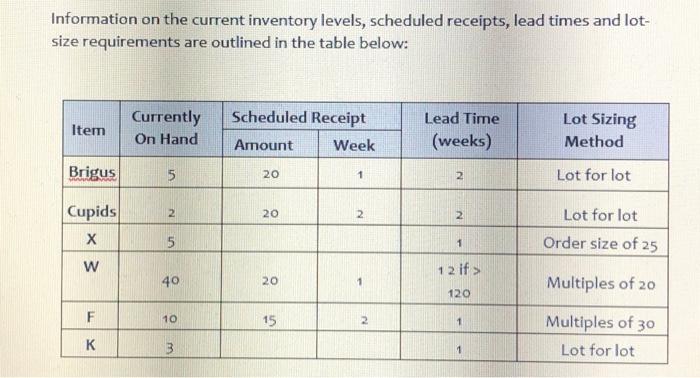

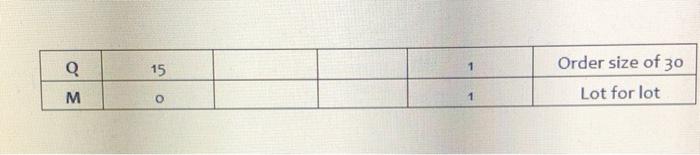

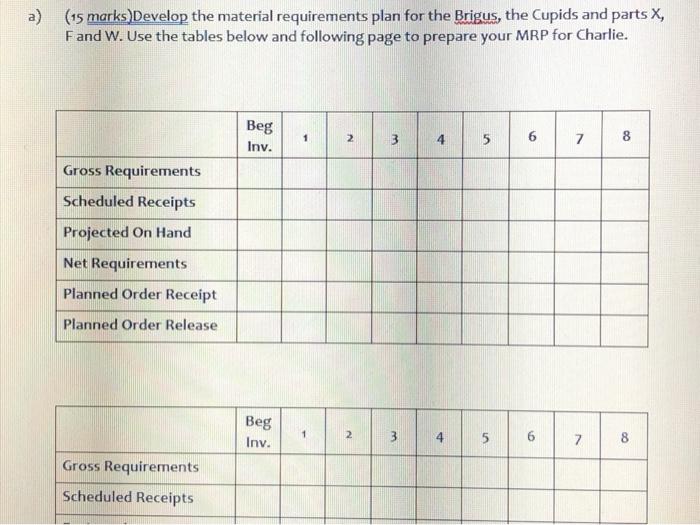

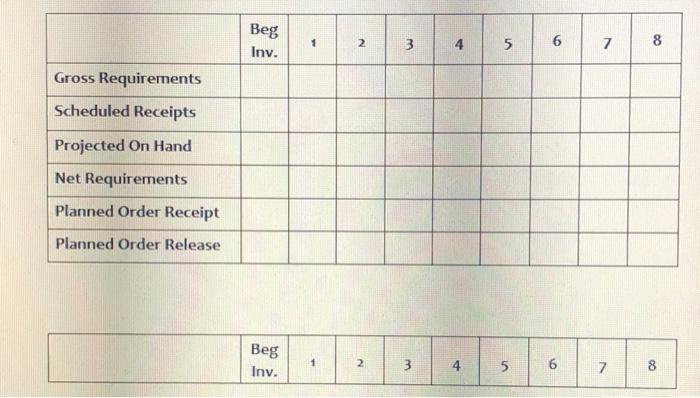

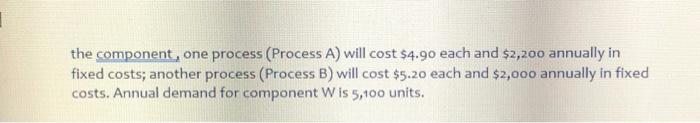

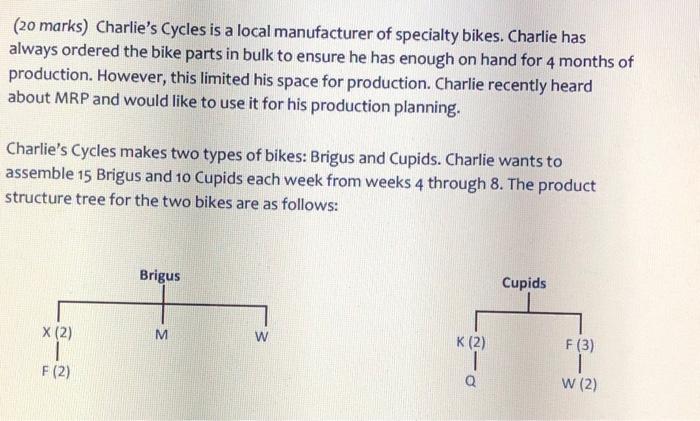

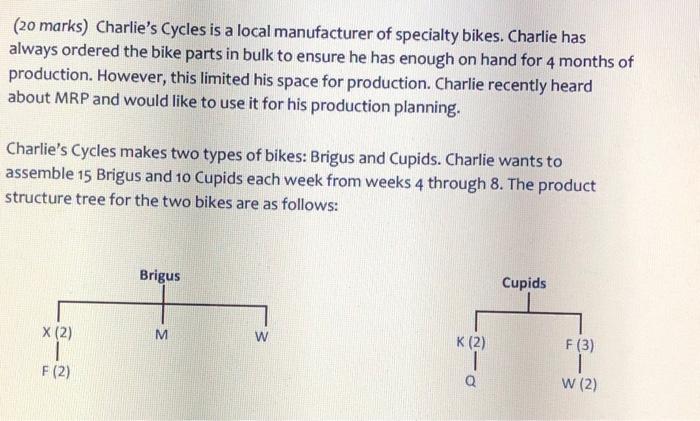

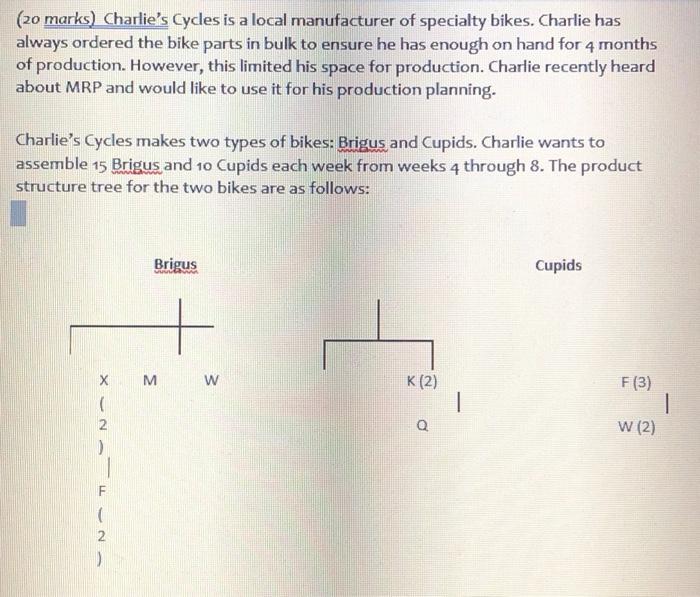

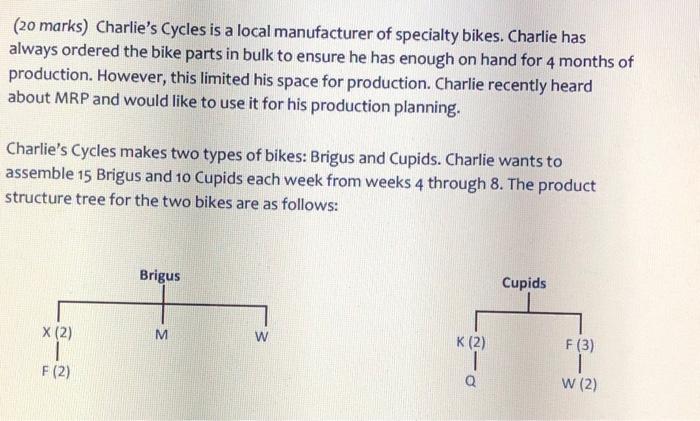

(20 marks) Charlie's Cycles is a local manufacturer of specialty bikes. Charlie has always ordered the bike parts in bulk to ensure he has enough on hand for 4 months of production. However, this limited his space for production. Charlie recently heard about MRP and would like to use it for his production planning. Charlie's Cycles makes two types of bikes: Brigus and Cupids. Charlie wants to assemble 15 Brigus and 10 Cupids each week from weeks 4 through 8. The product structure tree for the two bikes are as follows: Brigus Cupids VO M 3 K (2) F (3) X ( 2 Q W (2) F ( 2 ) Information on the current inventory levels, scheduled receipts, lead times and lot- size requirements are outlined in the table below: Item Currently On Hand Scheduled Receipt Amount Week Lead Time (weeks) Lot Sizing Method Brigus 5 20 1 2 Lot for lot 2 20 2 2 Cupids X Lot for lot Order size of 25 5 1 x 3 12 if > 40 20 1 Multiples of 20 120 F 10 15 2 1 K Multiples of 30 Lot for lot 3 1 Q 15 1 Order size of 30 Lot for lot M 0 1 a) (15 marks)Develop the material requirements plan for the Brigus, the Cupids and parts X, Fand W. Use the tables below and following page to prepare your MRP for Charlie. Beg Inv. 1 2 3 4 5 6 7 8 Gross Requirements Scheduled Receipts Projected On Hand Net Requirements Planned Order Receipt Planned Order Release Beg Inv. 1 2. 3 5 6 7 8 Gross Requirements Scheduled Receipts Beg Inv. 1 2 3 4 1 5 5 6 7 8 Gross Requirements Scheduled Receipts Projected On Hand Net Requirements Planned Order Receipt Planned Order Release Beg Inv. 1 2 3 5 6 7 8 b) (5 marks) Charlie's Cycles is considering making component W rather than purchasing it. Currently, they pay $5.10 each and transportation costs are $5 per case of 20. To make the component, one process (Process A) will cost $4.90 each and $2,200 annually in fixed costs; another process (Process B) will cost $5.20 each and $2,000 annually in fixed costs. Annual demand for component Wis 5,100 units. (20 marks) Charlie's Cycles is a local manufacturer of specialty bikes. Charlie has always ordered the bike parts in bulk to ensure he has enough on hand for 4 months of production. However, this limited his space for production. Charlie recently heard about MRP and would like to use it for his production planning. Charlie's Cycles makes two types of bikes: Brigus and Cupids. Charlie wants to assemble 15 Brigus and 10 Cupids each week from weeks 4 through 8. The product structure tree for the two bikes are as follows: Brigus Cupids M 3 K (2) X (2) | F (2) 1 Q F (3) | W (2) (20 marks) Charlie's Cycles is a local manufacturer of specialty bikes. Charlie has always ordered the bike parts in bulk to ensure he has enough on hand for 4 months of production. However, this limited his space for production. Charlie recently heard about MRP and would like to use it for his production planning. Charlie's Cycles makes two types of bikes: Brigus and Cupids. Charlie wants to assemble 15 Brigus and 10 Cupids each week from weeks 4 through 8. The product structure tree for the two bikes are as follows: Brigus Cupids VO M 3 K (2) F (3) X ( 2 Q W (2) F ( 2 ) Information on the current inventory levels, scheduled receipts, lead times and lot- size requirements are outlined in the table below: Item Currently On Hand Scheduled Receipt Amount Week Lead Time (weeks) Lot Sizing Method Brigus 5 20 1 2 Lot for lot 2 20 2 2 Cupids X Lot for lot Order size of 25 5 1 x 3 12 if > 40 20 1 Multiples of 20 120 F 10 15 2 1 K Multiples of 30 Lot for lot 3 1 Q 15 1 Order size of 30 Lot for lot M 0 1 a) (15 marks)Develop the material requirements plan for the Brigus, the Cupids and parts X, Fand W. Use the tables below and following page to prepare your MRP for Charlie. Beg Inv. 1 2 3 4 5 6 7 8 Gross Requirements Scheduled Receipts Projected On Hand Net Requirements Planned Order Receipt Planned Order Release Beg Inv. 1 2. 3 5 6 7 8 Gross Requirements Scheduled Receipts Beg Inv. 1 2 3 4 1 5 5 6 7 8 Gross Requirements Scheduled Receipts Projected On Hand Net Requirements Planned Order Receipt Planned Order Release Beg Inv. 1 2 3 5 6 7 8 b) (5 marks) Charlie's Cycles is considering making component W rather than purchasing it. Currently, they pay $5.10 each and transportation costs are $5 per case of 20. To make the component, one process (Process A) will cost $4.90 each and $2,200 annually in fixed costs; another process (Process B) will cost $5.20 each and $2,000 annually in fixed costs. Annual demand for component Wis 5,100 units. (20 marks) Charlie's Cycles is a local manufacturer of specialty bikes. Charlie has always ordered the bike parts in bulk to ensure he has enough on hand for 4 months of production. However, this limited his space for production. Charlie recently heard about MRP and would like to use it for his production planning. Charlie's Cycles makes two types of bikes: Brigus and Cupids. Charlie wants to assemble 15 Brigus and 10 Cupids each week from weeks 4 through 8. The product structure tree for the two bikes are as follows: Brigus Cupids M 3 K (2) X (2) | F (2) 1 Q F (3) | W (2)