Question: Please solve the following problem showing all steps, using what is asked in thr question. Also add screenshots of the data from the software or

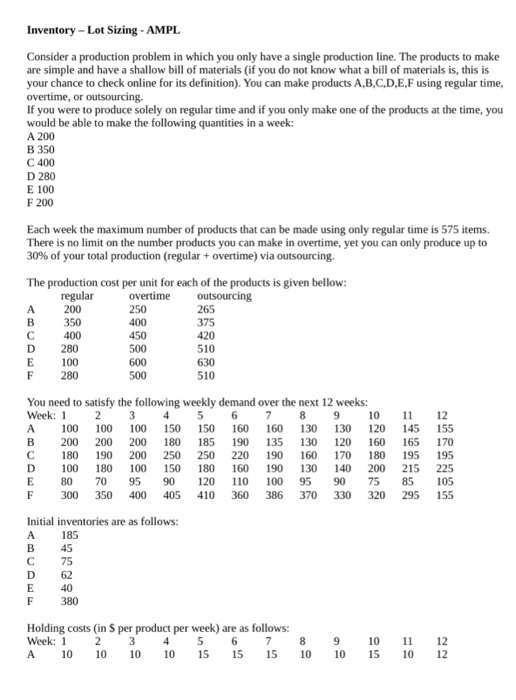

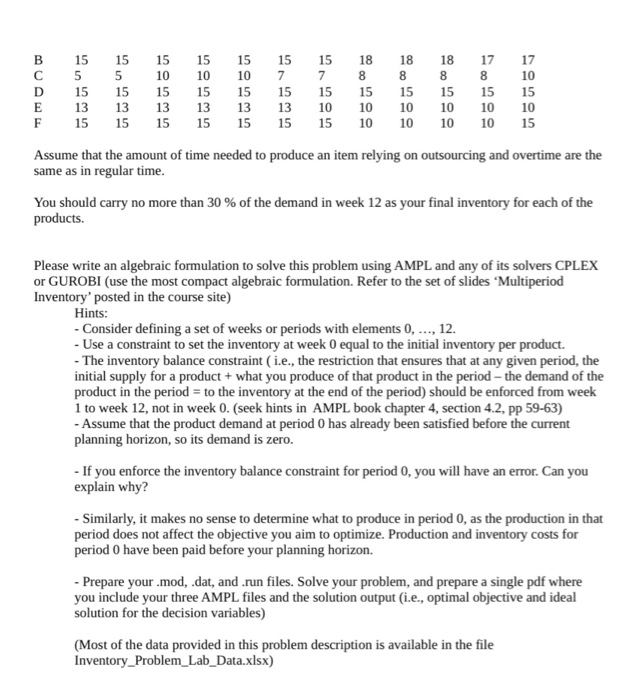

Inventory - Lot Sizing - AMPL Consider a production problem in which you only have a single production line. The products to make are simple and have a shallow bill of materials (if you do not know what a bill of materials is, this is your chance to check online for its definition). You can make products A,B,C,D,E,F using regular time, overtime, or outsourcing. If you were to produce solely on regular time and if you only make one of the products at the time, you would be able to make the following quantities in a week: A 200 B 350 C 400 D 280 E 100 F 200 D Each week the maximum number of products that can be made using only regular time is 575 items. There is no limit on the number products you can make in overtime, yet you can only produce up to 30% of your total production (regular + overtime) via outsourcing. The production cost per unit for each of the products is given bellow: regular overtime outsourcing A 200 250 265 B 350 400 375 400 450 420 280 500 510 E 100 600 630 F 280 500 510 You need to satisfy the following weekly demand over the next 12 weeks: Week: 1 2 3 4 5 6 7 8 10 11 12 A 100 100 100 150 150 160 160 130 130 120 145 155 200 200 200 180 185 190 135 130 120 160 165 170 180 190 200 250 250 220 190 160 170 180 195 195 D 100 180 100 150 160 190 130 140 200 215 225 80 70 95 90 120 110 100 95 90 75 85 105 F 300 350 400 405 410 360 386 370 330 320 295 155 9 B 180 E 45 Initial inventories are as follows: 185 B 75 D 62 E F 380 40 Holding costs (in S per product per week) are as follows: Week: 1 2 3 5 A 10 10 10 10 15 15 15 4 6 7 8 10 9 10 10 15 11 10 12 12 A B D E F 15 5 15 13 15 15 5 15 13 15 15 10 15 13 15 15 10 15 13 15 15 10 15 13 15 15 7 15 13 15 15 7 15 10 15 18 8 15 10 10 18 8 15 10 10 18 8 15 10 10 17 8 15 10 10 17 10 15 10 15 Assume that the amount of time needed to produce an item relying on outsourcing and overtime are the same as in regular time. You should carry no more than 30 % of the demand in week 12 as your final inventory for each of the products. Please write an algebraic formulation to solve this problem using AMPL and any of its solvers CPLEX or GUROBI (use the most compact algebraic formulation. Refer to the set of slides Multiperiod Inventory' posted in the course site) Hints: - Consider defining a set of weeks or periods with elements 0,..., 12. - Use a constraint to set the inventory at week 0 equal to the initial inventory per product. - The inventory balance constraint (i.e., the restriction that ensures that at any given period, the initial supply for a product + what you produce of that product in the period - the demand of the product in the period = to the inventory at the end of the period) should be enforced from week 1 to week 12, not in week 0. (seek hints in AMPL book chapter 4, section 4.2, pp 59-63) - Assume that the product demand at period 0 has already been satisfied before the current planning horizon, so its demand is zero. - If you enforce the inventory balance constraint for period 0, you will have an error. Can you explain why? - Similarly, it makes no sense to determine what to produce in period 0, as the production in that period does not affect the objective you aim to optimize. Production and inventory costs for period 0 have been paid before your planning horizon. - Prepare your.mod, .dat, and run files. Solve your problem, and prepare a single pdf where you include your three AMPL files and the solution output (i.e., optimal objective and ideal solution for the decision variables) (Most of the data provided in this problem description is available in the file Inventory_Problem_Lab_Data.xlsx) Inventory - Lot Sizing - AMPL Consider a production problem in which you only have a single production line. The products to make are simple and have a shallow bill of materials (if you do not know what a bill of materials is, this is your chance to check online for its definition). You can make products A,B,C,D,E,F using regular time, overtime, or outsourcing. If you were to produce solely on regular time and if you only make one of the products at the time, you would be able to make the following quantities in a week: A 200 B 350 C 400 D 280 E 100 F 200 D Each week the maximum number of products that can be made using only regular time is 575 items. There is no limit on the number products you can make in overtime, yet you can only produce up to 30% of your total production (regular + overtime) via outsourcing. The production cost per unit for each of the products is given bellow: regular overtime outsourcing A 200 250 265 B 350 400 375 400 450 420 280 500 510 E 100 600 630 F 280 500 510 You need to satisfy the following weekly demand over the next 12 weeks: Week: 1 2 3 4 5 6 7 8 10 11 12 A 100 100 100 150 150 160 160 130 130 120 145 155 200 200 200 180 185 190 135 130 120 160 165 170 180 190 200 250 250 220 190 160 170 180 195 195 D 100 180 100 150 160 190 130 140 200 215 225 80 70 95 90 120 110 100 95 90 75 85 105 F 300 350 400 405 410 360 386 370 330 320 295 155 9 B 180 E 45 Initial inventories are as follows: 185 B 75 D 62 E F 380 40 Holding costs (in S per product per week) are as follows: Week: 1 2 3 5 A 10 10 10 10 15 15 15 4 6 7 8 10 9 10 10 15 11 10 12 12 A B D E F 15 5 15 13 15 15 5 15 13 15 15 10 15 13 15 15 10 15 13 15 15 10 15 13 15 15 7 15 13 15 15 7 15 10 15 18 8 15 10 10 18 8 15 10 10 18 8 15 10 10 17 8 15 10 10 17 10 15 10 15 Assume that the amount of time needed to produce an item relying on outsourcing and overtime are the same as in regular time. You should carry no more than 30 % of the demand in week 12 as your final inventory for each of the products. Please write an algebraic formulation to solve this problem using AMPL and any of its solvers CPLEX or GUROBI (use the most compact algebraic formulation. Refer to the set of slides Multiperiod Inventory' posted in the course site) Hints: - Consider defining a set of weeks or periods with elements 0,..., 12. - Use a constraint to set the inventory at week 0 equal to the initial inventory per product. - The inventory balance constraint (i.e., the restriction that ensures that at any given period, the initial supply for a product + what you produce of that product in the period - the demand of the product in the period = to the inventory at the end of the period) should be enforced from week 1 to week 12, not in week 0. (seek hints in AMPL book chapter 4, section 4.2, pp 59-63) - Assume that the product demand at period 0 has already been satisfied before the current planning horizon, so its demand is zero. - If you enforce the inventory balance constraint for period 0, you will have an error. Can you explain why? - Similarly, it makes no sense to determine what to produce in period 0, as the production in that period does not affect the objective you aim to optimize. Production and inventory costs for period 0 have been paid before your planning horizon. - Prepare your.mod, .dat, and run files. Solve your problem, and prepare a single pdf where you include your three AMPL files and the solution output (i.e., optimal objective and ideal solution for the decision variables) (Most of the data provided in this problem description is available in the file Inventory_Problem_Lab_Data.xlsx)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts