Question: please solve this mass transfer question part d and e A thin (1.0-mm-thick) coat of fresh paint has just been sprayed over a 1.5m by

please solve this mass transfer question part d and e

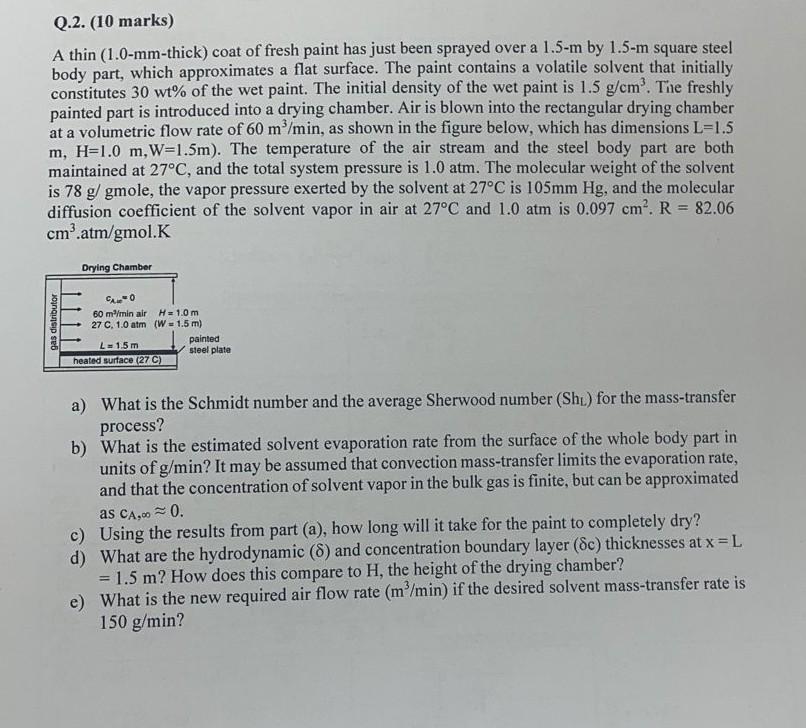

A thin (1.0-mm-thick) coat of fresh paint has just been sprayed over a 1.5m by 1.5m square steel body part, which approximates a flat surface. The paint contains a volatile solvent that initially constitutes 30wt% of the wet paint. The initial density of the wet paint is 1.5g/cm3. The freshly painted part is introduced into a drying chamber. Air is blown into the rectangular drying chamber at a volumetric flow rate of 60m3/min, as shown in the figure below, which has dimensions L=1.5 m,H=1.0m,W=1.5m). The temperature of the air stream and the steel body part are both maintained at 27C, and the total system pressure is 1.0atm. The molecular weight of the solvent is 78g/gmole, the vapor pressure exerted by the solvent at 27C is 105mmHg, and the molecular diffusion coefficient of the solvent vapor in air at 27C and 1.0atm is 0.097cm2.R=82.06 cm3atm/gmol.K a) What is the Schmidt number and the average Sherwood number (ShL) for the mass-transfer process? b) What is the estimated solvent evaporation rate from the surface of the whole body part in units of g/min ? It may be assumed that convection mass-transfer limits the evaporation rate, and that the concentration of solvent vapor in the bulk gas is finite, but can be approximated as cA,0. c) Using the results from part (a), how long will it take for the paint to completely dry? d) What are the hydrodynamic () and concentration boundary layer (c) thicknesses at x=L =1.5m ? How does this compare to H, the height of the drying chamber? e) What is the new required air flow rate (m3/min) if the desired solvent mass-transfer rate is 150g/min? A thin (1.0-mm-thick) coat of fresh paint has just been sprayed over a 1.5m by 1.5m square steel body part, which approximates a flat surface. The paint contains a volatile solvent that initially constitutes 30wt% of the wet paint. The initial density of the wet paint is 1.5g/cm3. The freshly painted part is introduced into a drying chamber. Air is blown into the rectangular drying chamber at a volumetric flow rate of 60m3/min, as shown in the figure below, which has dimensions L=1.5 m,H=1.0m,W=1.5m). The temperature of the air stream and the steel body part are both maintained at 27C, and the total system pressure is 1.0atm. The molecular weight of the solvent is 78g/gmole, the vapor pressure exerted by the solvent at 27C is 105mmHg, and the molecular diffusion coefficient of the solvent vapor in air at 27C and 1.0atm is 0.097cm2.R=82.06 cm3atm/gmol.K a) What is the Schmidt number and the average Sherwood number (ShL) for the mass-transfer process? b) What is the estimated solvent evaporation rate from the surface of the whole body part in units of g/min ? It may be assumed that convection mass-transfer limits the evaporation rate, and that the concentration of solvent vapor in the bulk gas is finite, but can be approximated as cA,0. c) Using the results from part (a), how long will it take for the paint to completely dry? d) What are the hydrodynamic () and concentration boundary layer (c) thicknesses at x=L =1.5m ? How does this compare to H, the height of the drying chamber? e) What is the new required air flow rate (m3/min) if the desired solvent mass-transfer rate is 150g/min

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts