Question: please solve this operations management case study. minne on hand Group 1(a) 27 April 22 The manufacturing process of a particular product consists of assembling

please solve this operations management case study.

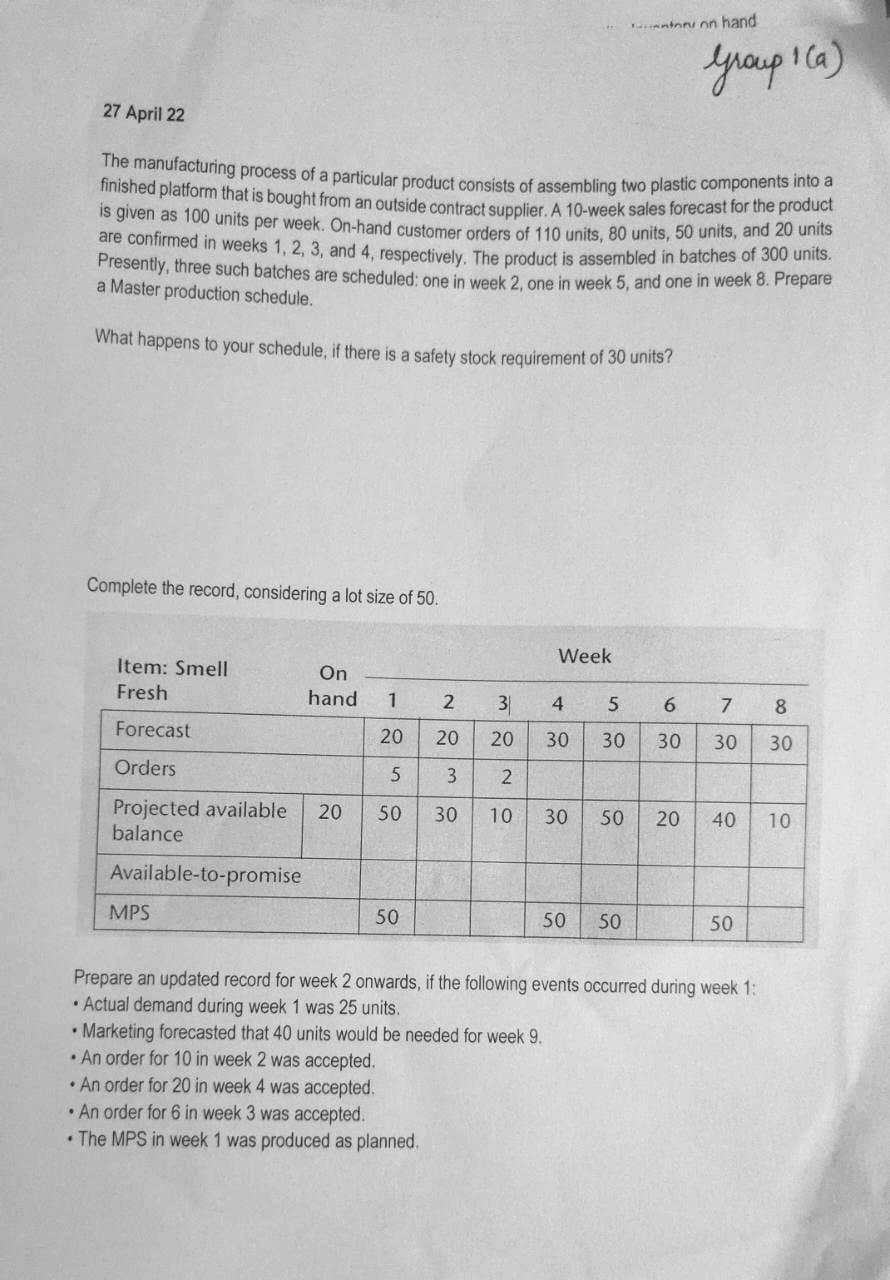

minne on hand Group 1(a) 27 April 22 The manufacturing process of a particular product consists of assembling two plastic components conduct finished platform that is bought from an outside contract supplier. A 10-week sales forecast for the product is given as 100 units per week. On-hand customer orders of 110 units, 80 units, 50 units, and 20 units are confirmed in weeks 1, 2, 3, and 4, respectively. The product is assembled in batches of 300 units. Presently, three such batches are scheduled: one in week 2, one in week 5, and one in week 8. Prepare a Master production schedule. What happens to your schedule, if there is a safety stock requirement of 30 units? Complete the record, considering a lot size of 50. Week Item: Smell Fresh On hand 1 2 3 4 5 6 7 8 Forecast 20 20 20 30 30 30 30 30 Orders 5 3 2 Projected available balance 20 50 30 10 30 50 20 40 10 Available-to-promise MPS 50 50 50 50 Prepare an updated record for week 2 onwards, if the following events occurred during week 1: Actual demand during week 1 was 25 units Marketing forecasted that 40 units would be needed for week 9. An order for 10 in week 2 was accepted. An order for 20 in week 4 was accepted. An order for 6 in week 3 was accepted. The MPS in week 1 was produced as planned minne on hand Group 1(a) 27 April 22 The manufacturing process of a particular product consists of assembling two plastic components conduct finished platform that is bought from an outside contract supplier. A 10-week sales forecast for the product is given as 100 units per week. On-hand customer orders of 110 units, 80 units, 50 units, and 20 units are confirmed in weeks 1, 2, 3, and 4, respectively. The product is assembled in batches of 300 units. Presently, three such batches are scheduled: one in week 2, one in week 5, and one in week 8. Prepare a Master production schedule. What happens to your schedule, if there is a safety stock requirement of 30 units? Complete the record, considering a lot size of 50. Week Item: Smell Fresh On hand 1 2 3 4 5 6 7 8 Forecast 20 20 20 30 30 30 30 30 Orders 5 3 2 Projected available balance 20 50 30 10 30 50 20 40 10 Available-to-promise MPS 50 50 50 50 Prepare an updated record for week 2 onwards, if the following events occurred during week 1: Actual demand during week 1 was 25 units Marketing forecasted that 40 units would be needed for week 9. An order for 10 in week 2 was accepted. An order for 20 in week 4 was accepted. An order for 6 in week 3 was accepted. The MPS in week 1 was produced as plannedStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock