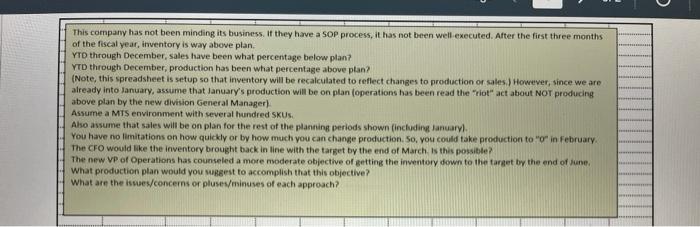

Question: please solve U This company has not been minding its business. If they have a SOP process, it has not been well executed. After the

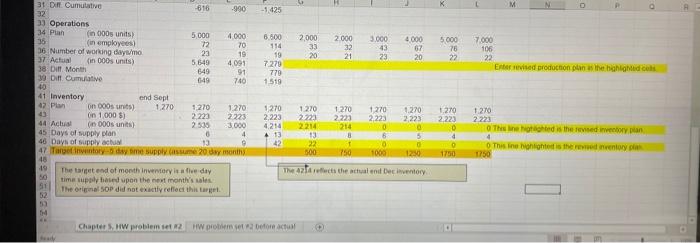

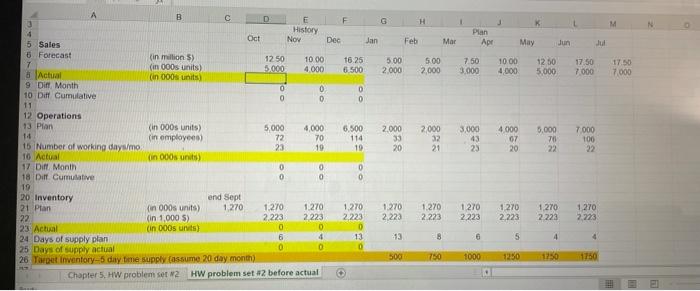

U This company has not been minding its business. If they have a SOP process, it has not been well executed. After the first three months of the fiscal year, inventory is way above plan. YTD through December, sales have been what percentage below plan? YTD through December, production has been what percentage above plan? (Note, this spreadsheet is setup so that inventory will be recalculated to reflect changes to production or sales. However, since we are already into January, assume that January's production will be on plan operations has been read the riot" act about NOT producing above plan by the new division General Manager) Assume a MTS environment with several hundred SKUS Also assume that sales will be on plan for the rest of the planning periods shown (including lancaryl You have no limitations on how quickly or by how much you can change production. So, you could take production to "o" in February The CFO would like the inventory brought back in line with the target by the end of March, Is this possible? The new VP of Operations has counseled a more moderate objective of getting the inventory down to the target by the end of June. What production plan would you suggest to accomplish that this objective? What are the issues/concerns or pluses/minuses of each approach? -1425 2,000 33 20 6.600 114 59 7.279 770 1.519 2.000 32 21 3.000 43 23 4000 67 20 5000 78 22 7.000 106 22 Ented production plans the higheid 3t Du Cumulative -616 -990 32 3) Operations 34 Plan (in 000 units) 5 000 4.000 36 in employees 12 70 36 Number of working daysmo 23 19 37 Actual in 00s units) 5.640 4.091 38. Dift Month 649 91 39 Di Cumulat 649 740 41 Inventory end Sept 47 Plan on 00s units) 1.270 1.270 1.270 on 1.000 $) 2.223 2223 44 Actual (000s units) 2.535 3.000 45 Days of supply plan 0 4 46 Days of supply actual 13 47 Tentory me supply as 20 month 48 19 The trend of months in very is five day 50 time supply based upon the next month's sales 51 The original SOP did not exactly reflect this bar 52 1.270 2223 9270 2.223 4214 10 42 1.270 2.223 1270 2723 2214 13 22 500 1.270 2.223 214 8 1 750 1270 2.223 0 6 5 4 0 1750 1 270 2.223 This in highted is the ed intory plan 4 This in highlighted is the inventory 1750 1000 1250 The aforects the actual e Decinventory H Chapter 5 w problem set 12 ww problemerDetom actum H K Plan Jan Feb Mar Ape May Jun Jul 5.00 2.000 5.00 2.000 7.50 3.000 10.00 4 000 12 50 5.000 17:50 7.000 17.50 17.000 A B D F History 4 Oct Nov 5 Sales Dec 5 Forecast (in milion 5) 12.50 1000 16.25 7 (in 00s units) 5000 4.000 6.500 8 Actual (in 000 units) 9 Dit Month 0 0 0 10 Diff Cumulative 0 0 0 11 12 Operations 13 Pian (in 00s units) 5.000 4,000 6.500 1 (in employees) 72 70 114 15 Number of working days/mo 23 19 19 10 Actual On 000 units) 17 Dift Month 0 0 0 18 Di Cumulative 0 0 0 19 20 Inventory end Sept 21 Plan (in 000s units) 1.270 1.270 1.270 1.270 22 (in 1.000 S) 2.223 2223 2.223 (in 00s units) 0 23 Actual 0 0 6 4 24 Days of supply plan 13 0 0 0 25 Days of supply actual 26 Torpet inventory-5 day time supply assume 20 day month Chapter 5 HW problem set 2 HW problem set 2 before actual 2.000 33 20 2,000 32 21 3.000 43 23 4.000 07 20 0.009 70 22 7 000 100 22 1.270 2 223 1.270 2.223 1270 2.223 1270 2.223 1.270 2.223 1270 2.223 13 8 5 4 4 500 750 1000 1250 1250 1750 . U This company has not been minding its business. If they have a SOP process, it has not been well executed. After the first three months of the fiscal year, inventory is way above plan. YTD through December, sales have been what percentage below plan? YTD through December, production has been what percentage above plan? (Note, this spreadsheet is setup so that inventory will be recalculated to reflect changes to production or sales. However, since we are already into January, assume that January's production will be on plan operations has been read the riot" act about NOT producing above plan by the new division General Manager) Assume a MTS environment with several hundred SKUS Also assume that sales will be on plan for the rest of the planning periods shown (including lancaryl You have no limitations on how quickly or by how much you can change production. So, you could take production to "o" in February The CFO would like the inventory brought back in line with the target by the end of March, Is this possible? The new VP of Operations has counseled a more moderate objective of getting the inventory down to the target by the end of June. What production plan would you suggest to accomplish that this objective? What are the issues/concerns or pluses/minuses of each approach? -1425 2,000 33 20 6.600 114 59 7.279 770 1.519 2.000 32 21 3.000 43 23 4000 67 20 5000 78 22 7.000 106 22 Ented production plans the higheid 3t Du Cumulative -616 -990 32 3) Operations 34 Plan (in 000 units) 5 000 4.000 36 in employees 12 70 36 Number of working daysmo 23 19 37 Actual in 00s units) 5.640 4.091 38. Dift Month 649 91 39 Di Cumulat 649 740 41 Inventory end Sept 47 Plan on 00s units) 1.270 1.270 1.270 on 1.000 $) 2.223 2223 44 Actual (000s units) 2.535 3.000 45 Days of supply plan 0 4 46 Days of supply actual 13 47 Tentory me supply as 20 month 48 19 The trend of months in very is five day 50 time supply based upon the next month's sales 51 The original SOP did not exactly reflect this bar 52 1.270 2223 9270 2.223 4214 10 42 1.270 2.223 1270 2723 2214 13 22 500 1.270 2.223 214 8 1 750 1270 2.223 0 6 5 4 0 1750 1 270 2.223 This in highted is the ed intory plan 4 This in highlighted is the inventory 1750 1000 1250 The aforects the actual e Decinventory H Chapter 5 w problem set 12 ww problemerDetom actum H K Plan Jan Feb Mar Ape May Jun Jul 5.00 2.000 5.00 2.000 7.50 3.000 10.00 4 000 12 50 5.000 17:50 7.000 17.50 17.000 A B D F History 4 Oct Nov 5 Sales Dec 5 Forecast (in milion 5) 12.50 1000 16.25 7 (in 00s units) 5000 4.000 6.500 8 Actual (in 000 units) 9 Dit Month 0 0 0 10 Diff Cumulative 0 0 0 11 12 Operations 13 Pian (in 00s units) 5.000 4,000 6.500 1 (in employees) 72 70 114 15 Number of working days/mo 23 19 19 10 Actual On 000 units) 17 Dift Month 0 0 0 18 Di Cumulative 0 0 0 19 20 Inventory end Sept 21 Plan (in 000s units) 1.270 1.270 1.270 1.270 22 (in 1.000 S) 2.223 2223 2.223 (in 00s units) 0 23 Actual 0 0 6 4 24 Days of supply plan 13 0 0 0 25 Days of supply actual 26 Torpet inventory-5 day time supply assume 20 day month Chapter 5 HW problem set 2 HW problem set 2 before actual 2.000 33 20 2,000 32 21 3.000 43 23 4.000 07 20 0.009 70 22 7 000 100 22 1.270 2 223 1.270 2.223 1270 2.223 1270 2.223 1.270 2.223 1270 2.223 13 8 5 4 4 500 750 1000 1250 1250 1750