Question: Please state decision variables, objective function and constraints Easley Apparel International manufactures clothing items around the world. It has currently contracted with a U.S. retail

Please state decision variables, objective function and constraints

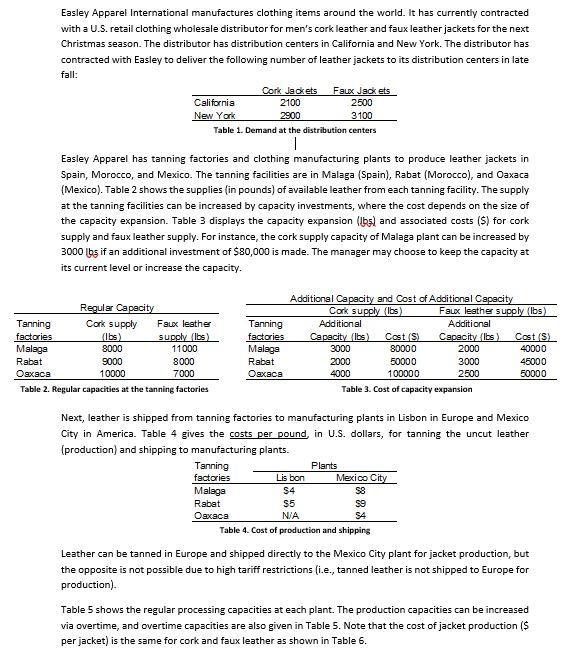

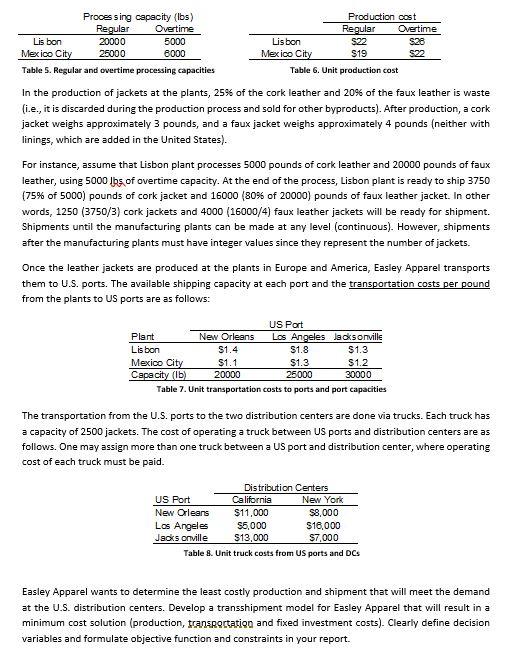

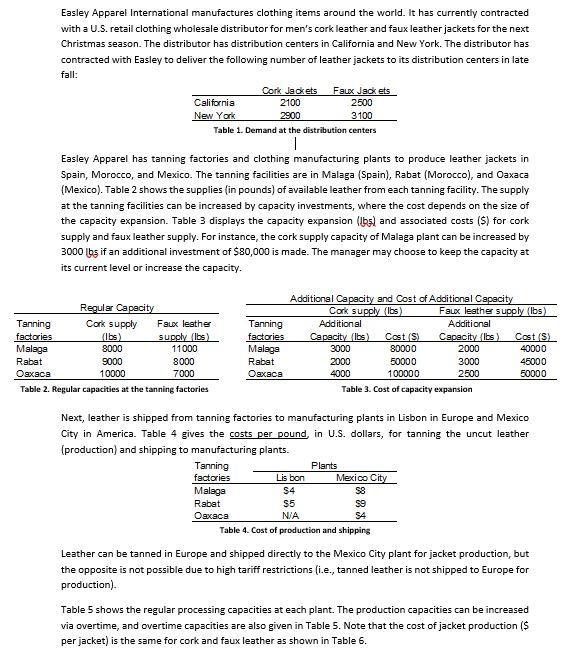

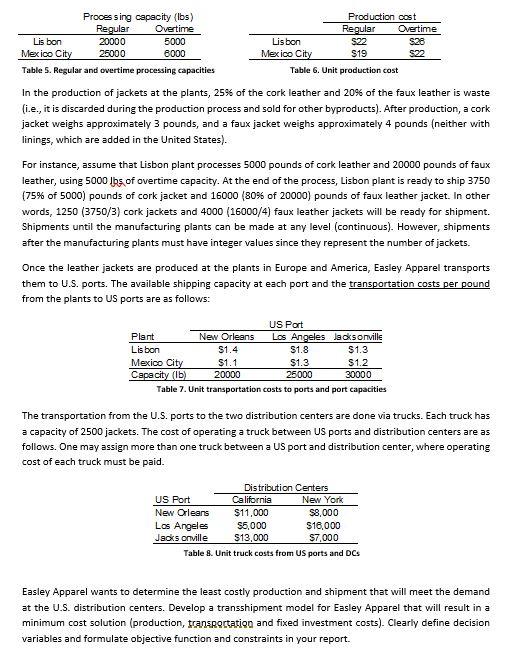

Easley Apparel International manufactures clothing items around the world. It has currently contracted with a U.S. retail clothing wholesale distributor for men's cork leather and faux leather jackets for the next Christmas season. The distributor has distribution centers in California and New York. The distributor has contracted with Easley to deliver the following number of leather jackets to its distribution centers in late fall: Cork Jackets Faux Jackets California 2100 2500 New York 2900 3100 Table 1. Demand at the distribution centers Easley Apparel has tanning factories and clothing manufacturing plants to produce leather jackets in Spain, Morocco, and Mexico. The tanning facilities are in Malaga (Spain), Rabat (Morocco), and Oaxaca (Mexico). Table 2 shows the supplies (in pounds) of available leather from each tanning facility. The supply at the tanning facilities can be increased by capacity investments, where the cost depends on the size of the capacity expansion Table 3 displays the capacity expansion (lbs) and associated costs (S) for cork supply and faux leather supply. For instance, the cork supply capacity of Malaga plant can be increased by 3000 lbs if an additional investment of $80,000 is made. The manager may choose to keep the capacity at its current level or increase the capacity. Regular Capacity Tanning Cork supply Faux leather factories (lbs) supply lbs) Malaga 8000 11000 Rabat 9000 8000 Oaxaca 10000 7000 Table 2. Regular capacities at the tanning factories Additional Capacity and Cost of Additional Capacity Cork supply (lbs) Faux leather supply (lbs) Tanning Additional Additional factories Capacity (lbs) Cost (S) Capacity lbs) Costs Malaga 3000 80000 2000 40000 Rabat 2000 50000 3000 45000 Oaxaca 4000 100000 2500 50000 Table 3. Cost of capacity expansion Lisbon S5 N/A S8 S9 S4 Next, leather is shipped from tanning factories to manufacturing plants in Lisbon in Europe and Mexico City in America. Table 4 gives the costs per pound in U.S. dollars, for tanning the uncut leather (production) and shipping to manufacturing plants. Tanning Plants factories Mexico City Malaga S4 Rabat Oaxaca Table 4. Cost of production and shipping Leather can be tanned in Europe and shipped directly to the Mexico City plant for jacket production, but the opposite is not possible due to high tariff restrictions (i.e., tanned leather is not shipped to Europe for production) Table 5 shows the regular processing capacities at each plant. The production capacities can be increased via overtime, and overtime capacities are also given in Table 5. Note that the cost of jacket production ($ per jacket) is the same for cork and faux leather as shown in Table 6. Processing capacity (lbs) Production cost Regular Overtime Regular Overtime Lis bon 20000 5000 Lisbon $22 S26 Mexico City 25000 8000 Mexico City S19 S22 Table 5. Regular and overtime processing capacities Table 6. Unit production cost In the production of jackets at the plants, 25% of the cork leather and 20% of the faux leather is waste (i.e., it is discarded during the production process and sold for other byproducts). After production, a cork jacket weighs approximately 3 pounds, and a faux jacket weighs approximately 4 pounds (neither with linings, which are added in the United States). For instance, assume that Lisbon plant processes 5000 pounds of cork leather and 20000 pounds of faux leather, using 5000 lbs of overtime capacity. At the end of the process, Lisbon plant is ready to ship 3750 (75% of 5000) pounds of cork jacket and 16000 (80% of 20000) pounds of faux leather jacket. In other words, 1250 (3750/3) cork jackets and 4000 (16000/4) faux leather jackets will be ready for shipment. Shipments until the manufacturing plants can be made at any level (continuous). However, shipments after the manufacturing plants must have integer values since they represent the number of jackets. Once the leather jackets are produced at the plants in Europe and America, Easley Apparel transports them to U.S. ports. The available shipping capacity at each port and the transportation costs per pound from the plants to US ports are as follows: US Port Plant New Orleans Los Angeles Jacksonville Lisbon $1.4 S1.8 $1.3 Mexico City $1.1 $1.2 Capacity (lb) 20000 25000 30000 Table 7. Unit transportation costs to ports and port capacities $1.3 The transportation from the U.S. ports to the two distribution centers are done via trucks. Each truck has a capacity of 2500 jackets. The cost of operating a truck between US ports and distribution centers are as follows. One may assign more than one truck between a US port and distribution center, where operating cost of each truck must be paid. Distribution Centers US Port California New York New Orleans $11,000 $8,000 Los Angeles $5,000 S16,000 Jacksonville $13,000 $7,000 Table 8. Unit truck costs from US ports and DCS Easley Apparel wants to determine the least costly production and shipment that will meet the demand at the U.S. distribution centers. Develop a transshipment model for Easley Apparel that will result in a minimum cost solution (production, transportation and fixed investment costs). Clearly define decision variables and formulate objective function and constraints in your report. Easley Apparel International manufactures clothing items around the world. It has currently contracted with a U.S. retail clothing wholesale distributor for men's cork leather and faux leather jackets for the next Christmas season. The distributor has distribution centers in California and New York. The distributor has contracted with Easley to deliver the following number of leather jackets to its distribution centers in late fall: Cork Jackets Faux Jackets California 2100 2500 New York 2900 3100 Table 1. Demand at the distribution centers Easley Apparel has tanning factories and clothing manufacturing plants to produce leather jackets in Spain, Morocco, and Mexico. The tanning facilities are in Malaga (Spain), Rabat (Morocco), and Oaxaca (Mexico). Table 2 shows the supplies (in pounds) of available leather from each tanning facility. The supply at the tanning facilities can be increased by capacity investments, where the cost depends on the size of the capacity expansion Table 3 displays the capacity expansion (lbs) and associated costs (S) for cork supply and faux leather supply. For instance, the cork supply capacity of Malaga plant can be increased by 3000 lbs if an additional investment of $80,000 is made. The manager may choose to keep the capacity at its current level or increase the capacity. Regular Capacity Tanning Cork supply Faux leather factories (lbs) supply lbs) Malaga 8000 11000 Rabat 9000 8000 Oaxaca 10000 7000 Table 2. Regular capacities at the tanning factories Additional Capacity and Cost of Additional Capacity Cork supply (lbs) Faux leather supply (lbs) Tanning Additional Additional factories Capacity (lbs) Cost (S) Capacity lbs) Costs Malaga 3000 80000 2000 40000 Rabat 2000 50000 3000 45000 Oaxaca 4000 100000 2500 50000 Table 3. Cost of capacity expansion Lisbon S5 N/A S8 S9 S4 Next, leather is shipped from tanning factories to manufacturing plants in Lisbon in Europe and Mexico City in America. Table 4 gives the costs per pound in U.S. dollars, for tanning the uncut leather (production) and shipping to manufacturing plants. Tanning Plants factories Mexico City Malaga S4 Rabat Oaxaca Table 4. Cost of production and shipping Leather can be tanned in Europe and shipped directly to the Mexico City plant for jacket production, but the opposite is not possible due to high tariff restrictions (i.e., tanned leather is not shipped to Europe for production) Table 5 shows the regular processing capacities at each plant. The production capacities can be increased via overtime, and overtime capacities are also given in Table 5. Note that the cost of jacket production ($ per jacket) is the same for cork and faux leather as shown in Table 6. Processing capacity (lbs) Production cost Regular Overtime Regular Overtime Lis bon 20000 5000 Lisbon $22 S26 Mexico City 25000 8000 Mexico City S19 S22 Table 5. Regular and overtime processing capacities Table 6. Unit production cost In the production of jackets at the plants, 25% of the cork leather and 20% of the faux leather is waste (i.e., it is discarded during the production process and sold for other byproducts). After production, a cork jacket weighs approximately 3 pounds, and a faux jacket weighs approximately 4 pounds (neither with linings, which are added in the United States). For instance, assume that Lisbon plant processes 5000 pounds of cork leather and 20000 pounds of faux leather, using 5000 lbs of overtime capacity. At the end of the process, Lisbon plant is ready to ship 3750 (75% of 5000) pounds of cork jacket and 16000 (80% of 20000) pounds of faux leather jacket. In other words, 1250 (3750/3) cork jackets and 4000 (16000/4) faux leather jackets will be ready for shipment. Shipments until the manufacturing plants can be made at any level (continuous). However, shipments after the manufacturing plants must have integer values since they represent the number of jackets. Once the leather jackets are produced at the plants in Europe and America, Easley Apparel transports them to U.S. ports. The available shipping capacity at each port and the transportation costs per pound from the plants to US ports are as follows: US Port Plant New Orleans Los Angeles Jacksonville Lisbon $1.4 S1.8 $1.3 Mexico City $1.1 $1.2 Capacity (lb) 20000 25000 30000 Table 7. Unit transportation costs to ports and port capacities $1.3 The transportation from the U.S. ports to the two distribution centers are done via trucks. Each truck has a capacity of 2500 jackets. The cost of operating a truck between US ports and distribution centers are as follows. One may assign more than one truck between a US port and distribution center, where operating cost of each truck must be paid. Distribution Centers US Port California New York New Orleans $11,000 $8,000 Los Angeles $5,000 S16,000 Jacksonville $13,000 $7,000 Table 8. Unit truck costs from US ports and DCS Easley Apparel wants to determine the least costly production and shipment that will meet the demand at the U.S. distribution centers. Develop a transshipment model for Easley Apparel that will result in a minimum cost solution (production, transportation and fixed investment costs). Clearly define decision variables and formulate objective function and constraints in your report