Question: Please try to solve ASAP. Thanks MRP Individual Case Study (W22) The Wood Products Company Why we do we keep missing our customer delivery dates?!

Please try to solve ASAP. Thanks

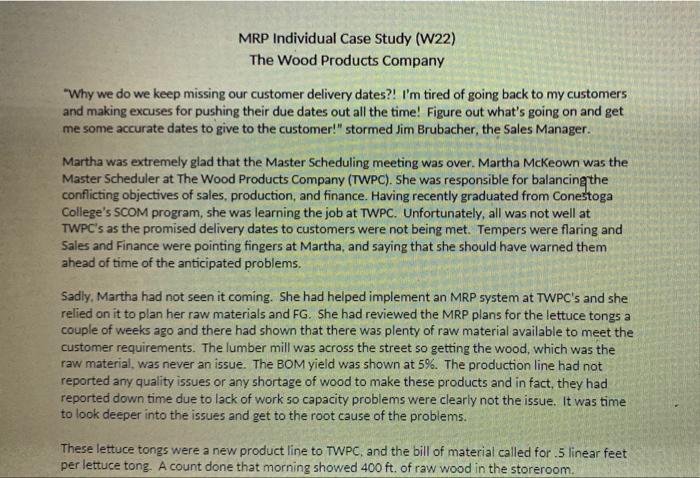

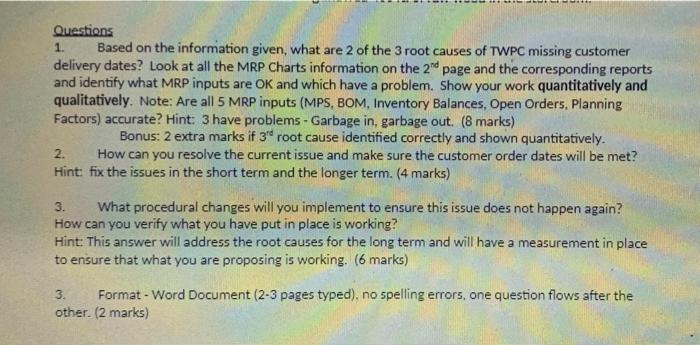

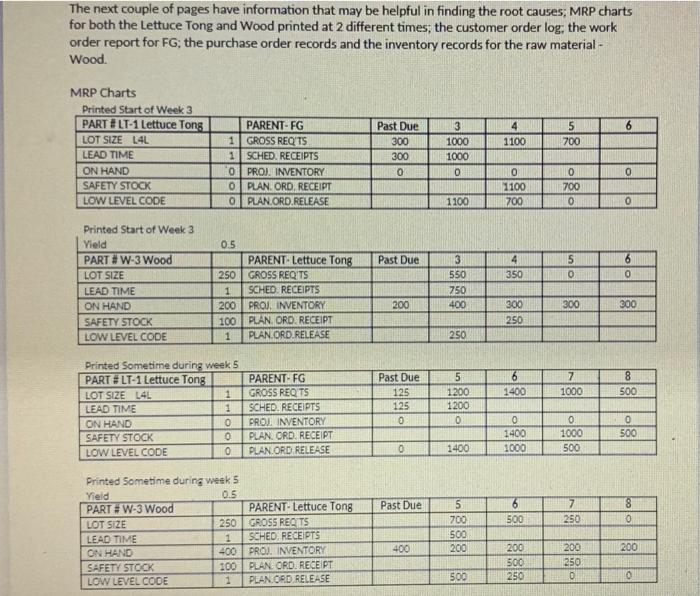

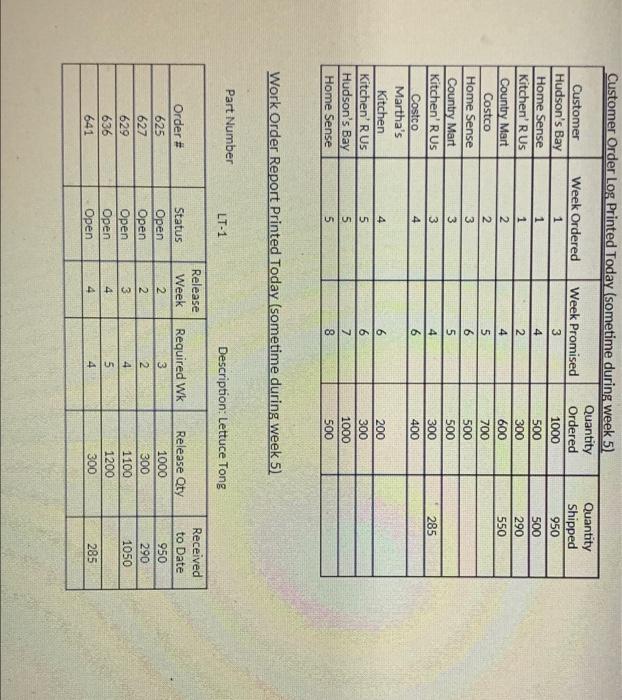

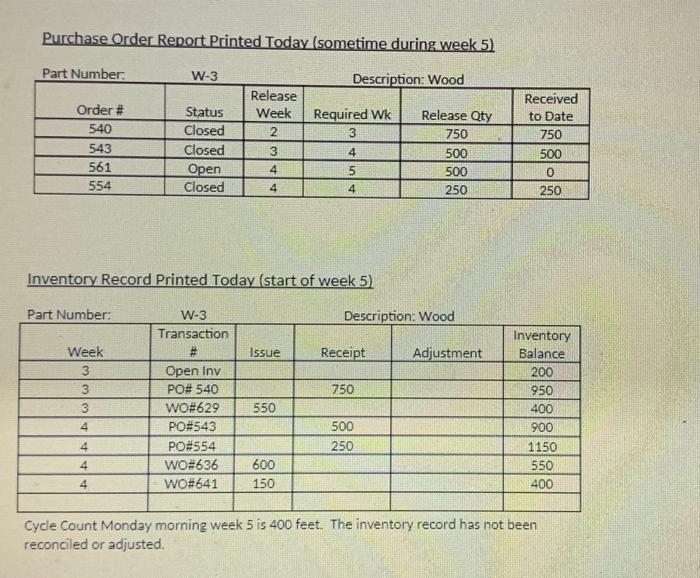

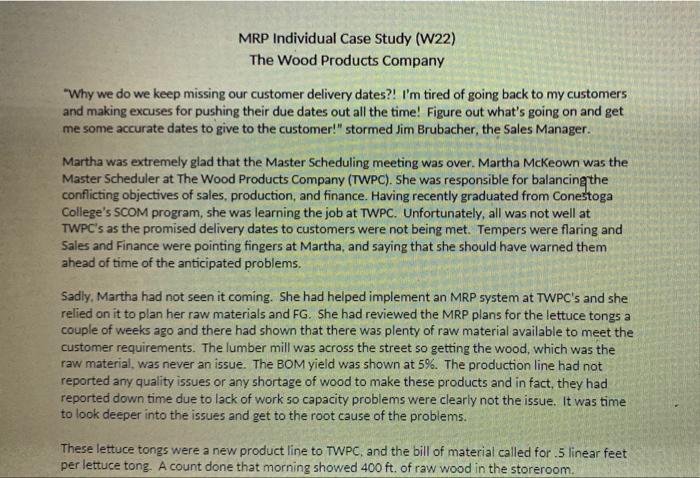

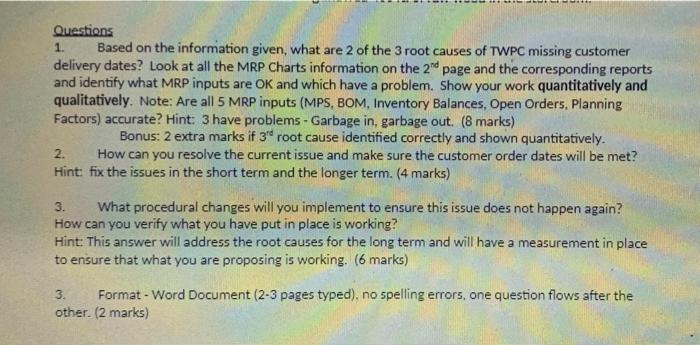

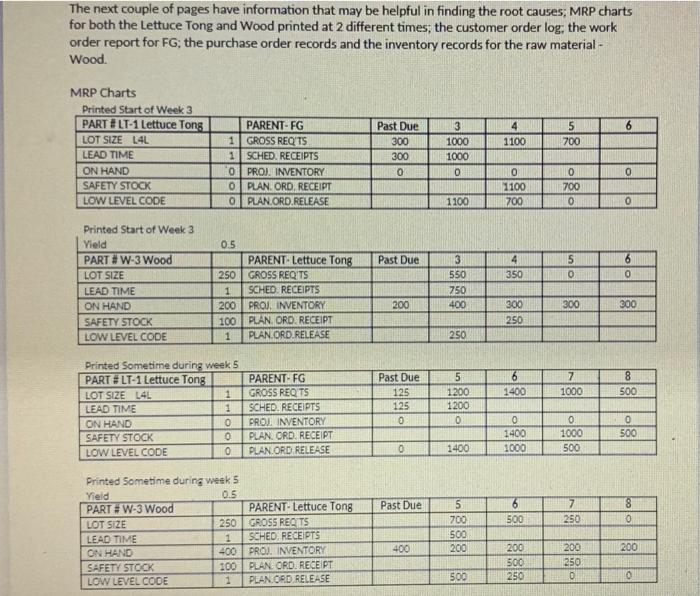

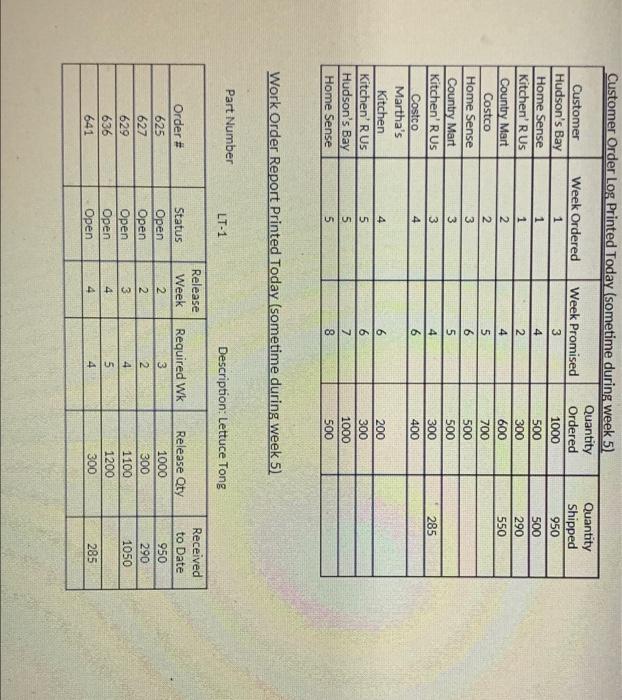

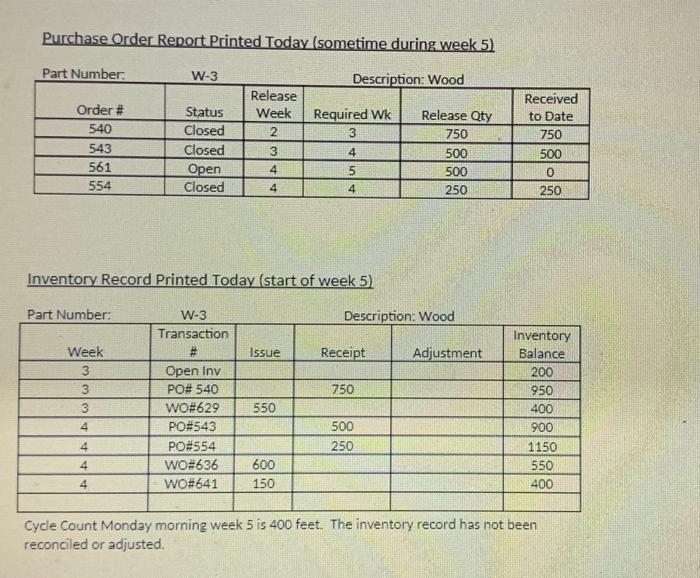

MRP Individual Case Study (W22) The Wood Products Company "Why we do we keep missing our customer delivery dates?! I'm tired of going back to my customers and making excuses for pushing their due dates out all the time! Figure out what's going on and get me some accurate dates to give to the customer!" stormed Jim Brubacher, the Sales Manager. Martha was extremely glad that the Master Scheduling meeting was over. Martha McKeown was the Master Scheduler at The Wood Products Company (TWPC). She was responsible for balancing the conflicting objectives of sales, production, and finance. Having recently graduated from Conestoga College's SCOM program, she was learning the job at TWPC. Unfortunately, all was not well at TWPC's as the promised delivery dates to customers were not being met. Tempers were flaring and Sales and Finance were pointing fingers at Martha, and saying that she should have warned them ahead of time of the anticipated problems. Sadly, Martha had not seen it coming. She had helped implement an MRP system at TWPC's and she relied on it to plan her raw materials and FG. She had reviewed the MRP plans for the lettuce tongs a couple of weeks ago and there had shown that there was plenty of raw material available to meet the customer requirements. The lumber mill was across the street so getting the wood, which was the raw material, was never an issue. The BOM yield was shown at 5%. The production line had not reported any quality issues or any shortage of wood to make these products and in fact, they had reported down time due to lack of work so capacity problems were clearly not the issue. It was time to look deeper into the issues and get to the root cause of the problems. These lettuce tongs were a new product line to TWPC, and the bill of material called for 5 linear feet per lettuce tong. A count done that morning showed 400 ft. of raw wood in the storeroom. Questions 1. Based on the information given, what are 2 of the 3 root causes of TWPC missing customer delivery dates? Look at all the MRP Charts information on the 2nd page and the corresponding reports and identify what MRP inputs are OK and which have a problem. Show your work quantitatively and qualitatively. Note: Are all 5 MRP inputs (MPS, BOM, Inventory Balances, Open Orders, Planning Factors) accurate? Hint: 3 have problems - Garbage in, garbage out. (8 marks) Bonus: 2 extra marks if 3d root cause identified correctly and shown quantitatively. 2. How can you resolve the current issue and make sure the customer order dates will be met? Hint: fix the issues in the short term and the longer term. (4 marks) 3. What procedural changes will you implement to ensure this issue does not happen again? How can you verify what you have put in place is working? Hint: This answer will address the root causes for the long term and will have a measurement in place to ensure that what you are proposing is working. (6 marks) 3. Format - Word Document (2-3 pages typed), no spelling errors, one question flows after the other. (2 marks) The next couple of pages have information that may be helpful in finding the root causes; MRP charts for both the Lettuce Tong and Wood printed at 2 different times, the customer order log: the work order report for FG; the purchase order records and the inventory records for the raw material - Wood. 6 MRP Charts Printed Start of Week 3 PART #LT-1 Lettuce Tons LOT SIZE L4L LEAD TIME ON HAND SAFETY STOCK LOW LEVEL CODE 4 1100 5 700 PARENT-FG 1 GROSS REQ TS 1 SCHED. RECEIPTS O PROJ. INVENTORY 0 | PLAN. ORD, RECEIPT O PLAN.ORD. RELEASE Past Due 300 300 0 3 1000 1000 0 0 0 1100 700 0 700 0 1100 0 Past Due 4 350 5 0 Printed Start of Week 3 Yield PART #W-3 Wood LOT SIZE LEAD TIME ON HAND SAFETY STOCK LOW LEVEL CODE 0.5 PARENT Lettuce Tong 250 GROSS REQITS 1 SCHED. RECEIPTS 200 PROJ, INVENTORY 100 PLAN. ORD. RECEIPT 1 PLAN.ORD RELEASE 3 550 750 400 18|ola 200 300 300 300 250 250 6 1400 7 1000 8 500 Printed Sometime during week 5 PART. LT-1 Lettuce Tong PARENT-FG LOT SIZE L4L 1 GROSS REQ TS LEAD TIME 1 SCHED. RECEIPTS ON HAND 0 PROJ. INVENTORY SAFETY STOCK PLAN. ORD. RECEIPT LOW LEVEL CODE PLAN.ORD RELEASE Past Due 125 125 0 5 1200 1200 0 0 1400 1000 lolo 0 1000 500 0 500 0 1400 Past Due 8 6 500 7 250 Printed Sometime during week 5 Yield 0.5 PART #W-3 Wood PARENT- Lettuce Tong LOT SIZE 250 GROSS REQ TS LEAD TIME 1 SCHED. RECEPTS ON HAND 400 PROJ. INVENTORY SAFETY STOCK 100 PLAN ORD. RECEPT LOW LEVEL CODE 1 PLAN.ORD RELEASE 5 700 500 200 400 200 200 500 250 200 250 0 500 Quantity Shipped 950 500 290 550 Customer Order Log Printed Today (sometime during week 5) Quantity Customer Week Ordered Week Promised Ordered Hudson's Bay 1 3 1000 Home Sense 1 4 500 Kitchen' R Us 1 2 300 Country Mart 2 4 600 Costco 2 5 700 Home Sense 3 6 500 Country Mart 3 5 500 Kitchen' RUS 3 4 300 Costco 4 6 400 Martha's Kitchen 4 6 200 Kitchen' RUS 5 6 300 Hudson's Bay 5 7 1000 Home Sense 5 8 500 285 4 Work Order Report Printed Today (sometime during week 5) Part Number LT-1 Description: Lettuce Tong Required WK 3 Order # 625 627 629 636 641 Status Open Open Open Open Open Release Week 2 2 3 4 Received to Date 950 290 1050 Release Qty 1000 300 1100 1200 300 2 4 5 4 285 Purchase Order Report Printed Today (sometime during week 5) Part Number: W-3 Description: Wood Release Week 2 Received to Date 750 Order # 540 543 561 554 Status Closed Closed Open Closed Required Wk 3 4 3 4 Release Qty 750 500 500 250 500 0 5 4 4 250 Inventory Record Printed Today (start of week 5) Part Number: Description: Wood Issue Week 3 Receipt Adjustment 750 3 3 4 W-3 Transaction # Open Inv PO# 540 WO#629 PO#543 PO#554 WO#636 WO#641 550 Inventory Balance 200 950 400 900 1150 550 400 500 250 4 4 600 150 4 Cycle Count Monday morning week 5 is 400 feet. The inventory record has not been reconciled or adjusted

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock