Question: Please type the answer by computer, so i can see it clearly, thank you!!! Assume you've been offered an internship position following a successful interview.

Please type the answer by computer, so i can see it clearly, thank you!!!

Assume you've been offered an internship position following a successful interview. As an intern, you will be required to research inventory issues and produce a material requirement plan (MRP) for a new product T, whose structure and other pertinent information are as follows:

| Component/Subassembly | Number Required | Lead Time |

| Subassembly A | 3 | 2 weeks |

| Component B | 4 | 2 weeks |

| Subassembly A | Number Required | Lead Time |

| Component B | 2 | 2 weeks |

| Component C | 5 | 1 week |

Subassembly A and Components B and C are purchased from external suppliers.

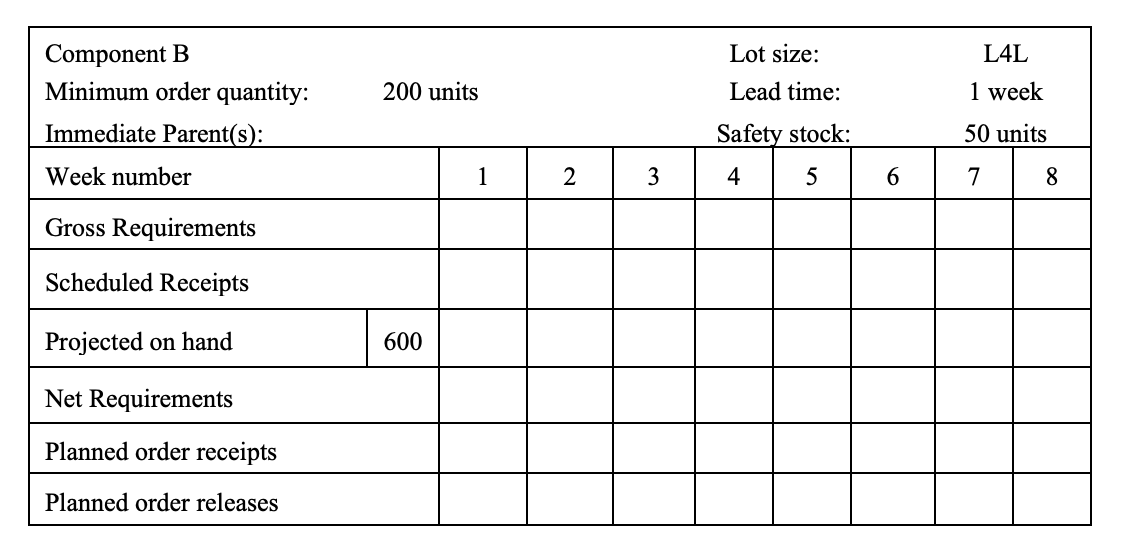

Both Components B and C are also sold to customers. A particular customer of Component B requires 140 units in week 2 and 50 units in week 5 while another customer of Component C needs 300 in week 3 and 200 in week 6. The beginning inventory of Subassembly A is 200 units, the beginning inventories of Components B and C are 600 and 100 units, respectively. There is no inventory of product T.

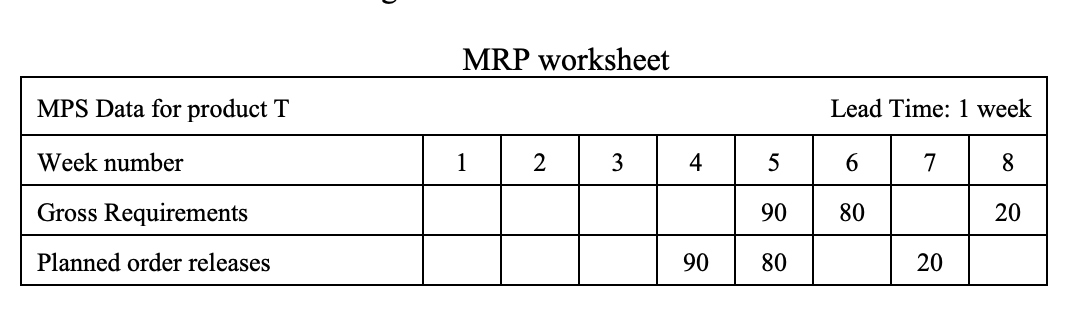

The Master Production Schedule (MPS) data of product T as well as the lot size, lead time, safety stock requirement and minimum order quantity for Subassembly A, Components B and C are shown in the following worksheets.

Based on the data given, answer the following questions. You can use the above MRP worksheets to calculate the material requirements.

Question:

Determine the planned order releases for Subassembly B.

(Please show the calculation step)

| Week number |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Planned order releases | ||||||||||

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts