Question: please use excel process flow add in to solve and explain the steps Labwork-1 is a group work. Please, read the problem carefully and complete

please use excel process flow add in to solve

and explain the steps

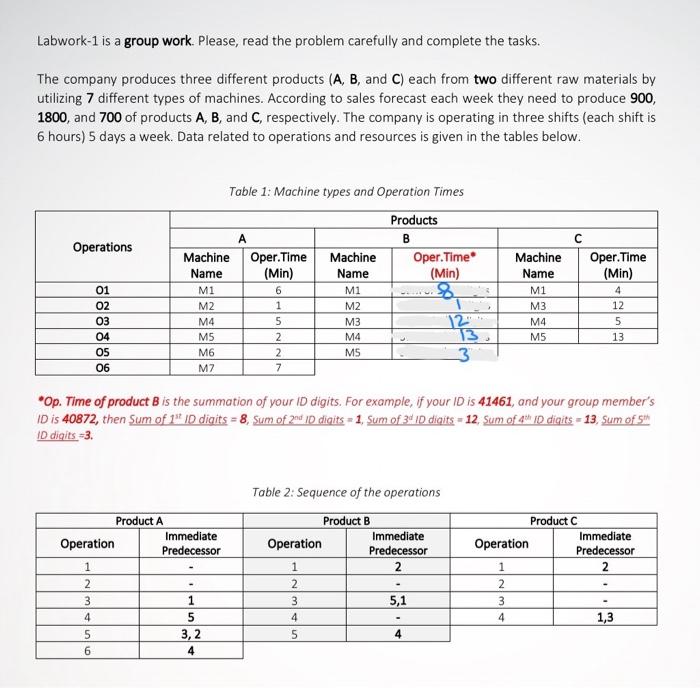

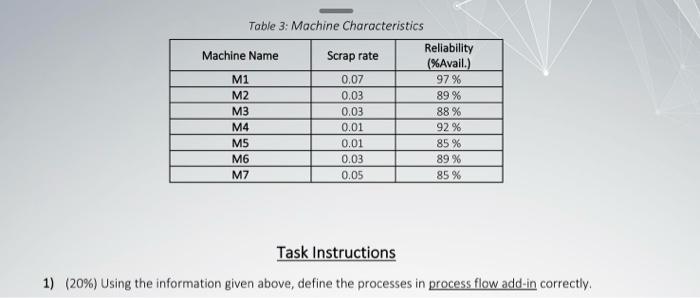

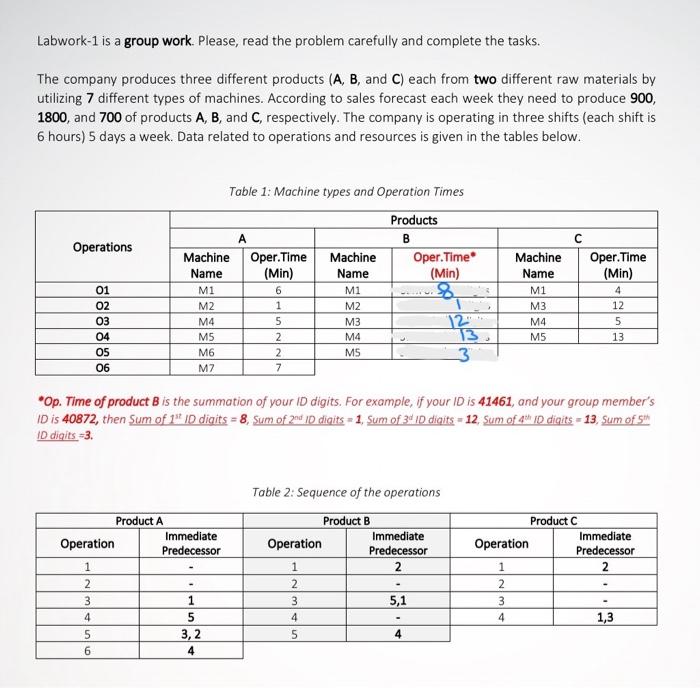

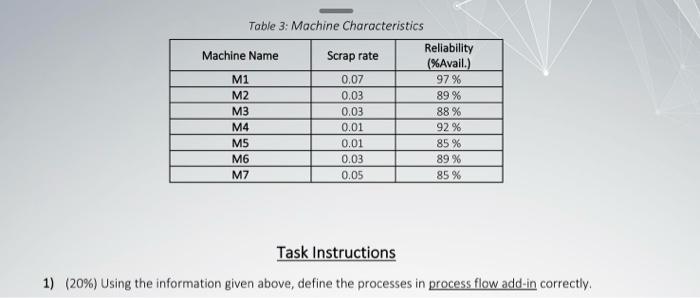

Labwork-1 is a group work. Please, read the problem carefully and complete the tasks. The company produces three different products (A, B, and C) each from two different raw materials by utilizing 7 different types of machines. According to sales forecast each week they need to produce 900, 1800, and 700 of products A, B, and C, respectively. The company is operating in three shifts (each shift is 6 hours) 5 days a week. Data related to operations and resources is given in the tables below. Operations Table 1: Machine types and Operation Times Products A B Machine Oper. Time Machine Oper. Time Name (Min) Name (Min) Mi 6 M1 M2 1 M2 M4 5 M3 12 MS 2 M4 M6 2 MS 3 M7 7 01 02 03 04 OS 06 Machine Name M1 M3 M4 M5 Oper. Time (Min) 4 12 5 13 13 *Op. Time of product B is the summation of your ID digits. For example, if your ID is 41461, and your group member's ID is 40872, then Sum of 1st ID digits = 8. Sum of 2nd ID digits = 1, Sum of 3d ID digits = 12. Sum of 4th 10 digits = 13 Sum of 5th ID digits +3. Product A Immediate Operation Predecessor 1 2 3 1 4 5 5 3,2 6 4 Table 2: Sequence of the operations Product B Operation Immediate Predecessor 1 2 2 3 5,1 4 5 4 Product C Immediate Operation Predecessor 1 2 2 3 4 1,3 - Toble 3: Machine Characteristics Reliability Machine Name Scrap rate (%Avail.) M1 0.07 97 % M2 0.03 89 % M3 0.03 88 % M4 0.01 92 % MS 0.01 85 % M6 0.03 89 % M7 0.05 85 % Task Instructions 1) (20%) Using the information given above, define the processes in process flow add-in correctly. Labwork-1 is a group work. Please, read the problem carefully and complete the tasks. The company produces three different products (A, B, and C) each from two different raw materials by utilizing 7 different types of machines. According to sales forecast each week they need to produce 900, 1800, and 700 of products A, B, and C, respectively. The company is operating in three shifts (each shift is 6 hours) 5 days a week. Data related to operations and resources is given in the tables below. Operations Table 1: Machine types and Operation Times Products A B Machine Oper. Time Machine Oper. Time Name (Min) Name (Min) Mi 6 M1 M2 1 M2 M4 5 M3 12 MS 2 M4 M6 2 MS 3 M7 7 01 02 03 04 OS 06 Machine Name M1 M3 M4 M5 Oper. Time (Min) 4 12 5 13 13 *Op. Time of product B is the summation of your ID digits. For example, if your ID is 41461, and your group member's ID is 40872, then Sum of 1st ID digits = 8. Sum of 2nd ID digits = 1, Sum of 3d ID digits = 12. Sum of 4th 10 digits = 13 Sum of 5th ID digits +3. Product A Immediate Operation Predecessor 1 2 3 1 4 5 5 3,2 6 4 Table 2: Sequence of the operations Product B Operation Immediate Predecessor 1 2 2 3 5,1 4 5 4 Product C Immediate Operation Predecessor 1 2 2 3 4 1,3 - Toble 3: Machine Characteristics Reliability Machine Name Scrap rate (%Avail.) M1 0.07 97 % M2 0.03 89 % M3 0.03 88 % M4 0.01 92 % MS 0.01 85 % M6 0.03 89 % M7 0.05 85 % Task Instructions 1) (20%) Using the information given above, define the processes in process flow add-in correctly Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock