Question: Please view the question below in the image to solve. Please note: The answer will not be $20,150. The Britts & Straggon company manufactures small

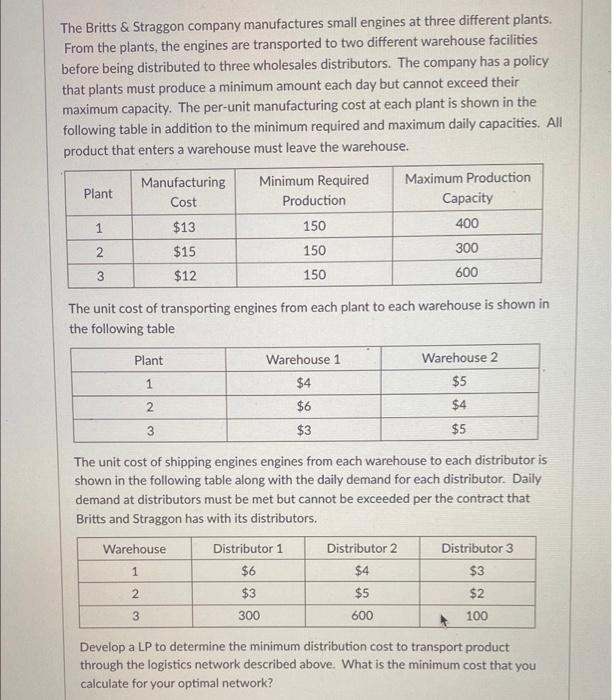

The Britts & Straggon company manufactures small engines at three different plants. From the plants, the engines are transported to two different warehouse facilities before being distributed to three wholesales distributors. The company has a policy that plants must produce a minimum amount each day but cannot exceed their maximum capacity. The per-unit manufacturing cost at each plant is shown in the following table in addition to the minimum required and maximum daily capacities. All product that enters a warehouse must leave the warehouse. Plant Manufacturing Cost Minimum Required Production Maximum Production Capacity 400 1 $13 150 2 300 $15 $12 150 150 3 600 The unit cost of transporting engines from each plant to each warehouse is shown in the following table Plant Warehouse 1 $4 $6 Warehouse 2 $5 1 2 $4 3 $3 $5 The unit cost of shipping engines engines from each warehouse to each distributor is shown in the following table along with the daily demand for each distributor. Daily demand at distributors must be met but cannot be exceeded per the contract that Britts and Straggon has with its distributors. Warehouse Distributor 1 Distributor 2 Distributor 3 $6 $4 $3 $3 $5 $2 300 600 100 1 2 3 Develop a LP to determine the minimum distribution cost to transport product through the logistics network described above. What is the minimum cost that you calculate for your optimal network

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts