Question: please write the objective + constraint also use excel to solve it using solver. but make sure the length is 12 18 30 45 60

please write the objective + constraint also use excel to solve it using solver. but make sure the length is 12 18 30 45 60

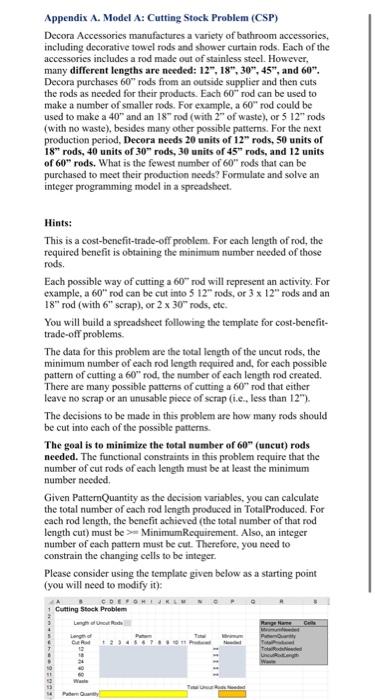

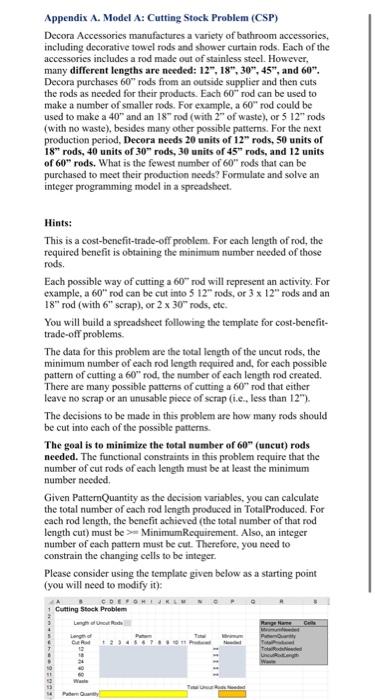

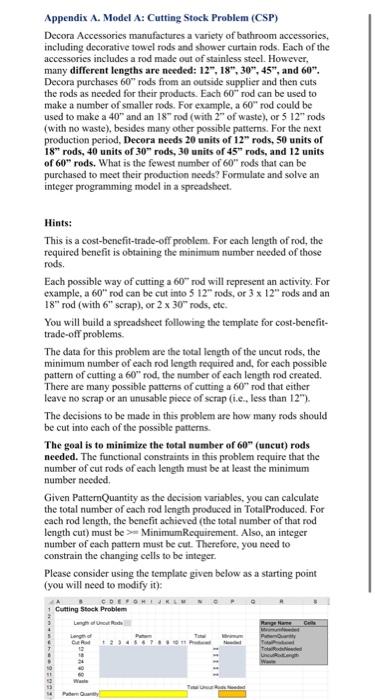

Appendix A. Model A: Cutting Stock Problem (CSP) Decora Accessories manufactures a varicty of bathroom accessories, including decorative towel rods and shower curtain rods. Each of the accessories includes a rod made out of stainless steel. However, many different lengths are needed: 12,18,30,45, and 60. Decora purchases 60 rods from an outside supplier and then cuts the rods as needed for their products. Each 60 rod can be used to make a number of smaller rods. For example, a 60 rod could be used to make a 40 and an 18 rod (with 2 of waste), or 512 rods (with no waste), besides many other possible pattems. For the next production period, Decora needs 20 units of 12" rods, 50 units of 18 rods, 40 units of 30 reds, 30 units of 45 rods, and 12 units of 60 rods. What is the fewest number of 60 rods that can be purchased to meet their production needs? Formulate and solve an integer programming model in a spreadsheet. Hints: This is a cost-benefit-trade-off problem. For each length of rod, the required benefit is obtaining the minimum number needed of those rods. Each possible way of cutting a 60rod will represent an activity. For example, a 60 rod can be cut into 512 rods, or 312 rods and an 18 rod (with 6 scrap), or 230 rods, etc. You will build a spreadsheet following the template for cost-benefittrade-off problems. The data for this problem are the total length of the uncut rods, the minimum number of each rod length required and, for each possible pattern of cutting a 60 rod, the number of each length rod created. There are many possible pattems of cutting a 60 rod that either leave no scrap or an unusable piece of scrap (i.e., less than 12 ). The decisions to be made in this problem are how many rods should be cut inte each of the possible pattems. The goal is to minimize the total number of 60 (uncut) rods needed. The functional constraints in this problem require that the number of cut rods of each length must be at least the minimum number needed. Given PattemQuantity as the decision variables, you can calculate the total number of each rod length produced in TotalProduced. For each rod length, the benefit achieved (the total number of that rod length cut) must be > - MinimumRequirement. Also, an integer number of each pattem must be cut. Therefore, you need to constrain the changing cells to be integer. Please consider using the template given below as a starting point (you will need to modify it): Appendix A. Model A: Cutting Stock Problem (CSP) Decora Accessories manufactures a varicty of bathroom accessories, including decorative towel rods and shower curtain rods. Each of the accessories includes a rod made out of stainless steel. However, many different lengths are needed: 12,18,30,45, and 60. Decora purchases 60 rods from an outside supplier and then cuts the rods as needed for their products. Each 60 rod can be used to make a number of smaller rods. For example, a 60 rod could be used to make a 40 and an 18 rod (with 2 of waste), or 512 rods (with no waste), besides many other possible pattems. For the next production period, Decora needs 20 units of 12" rods, 50 units of 18 rods, 40 units of 30 reds, 30 units of 45 rods, and 12 units of 60 rods. What is the fewest number of 60 rods that can be purchased to meet their production needs? Formulate and solve an integer programming model in a spreadsheet. Hints: This is a cost-benefit-trade-off problem. For each length of rod, the required benefit is obtaining the minimum number needed of those rods. Each possible way of cutting a 60rod will represent an activity. For example, a 60 rod can be cut into 512 rods, or 312 rods and an 18 rod (with 6 scrap), or 230 rods, etc. You will build a spreadsheet following the template for cost-benefittrade-off problems. The data for this problem are the total length of the uncut rods, the minimum number of each rod length required and, for each possible pattern of cutting a 60 rod, the number of each length rod created. There are many possible pattems of cutting a 60 rod that either leave no scrap or an unusable piece of scrap (i.e., less than 12 ). The decisions to be made in this problem are how many rods should be cut inte each of the possible pattems. The goal is to minimize the total number of 60 (uncut) rods needed. The functional constraints in this problem require that the number of cut rods of each length must be at least the minimum number needed. Given PattemQuantity as the decision variables, you can calculate the total number of each rod length produced in TotalProduced. For each rod length, the benefit achieved (the total number of that rod length cut) must be > - MinimumRequirement. Also, an integer number of each pattem must be cut. Therefore, you need to constrain the changing cells to be integer. Please consider using the template given below as a starting point (you will need to modify it)