Question: pls solve this task as soon as possible! Case Study for New Dispatch Reles Problem 1: Retrieving (1). Airlift follows the IT inventory system as

pls solve this task as soon as possible!

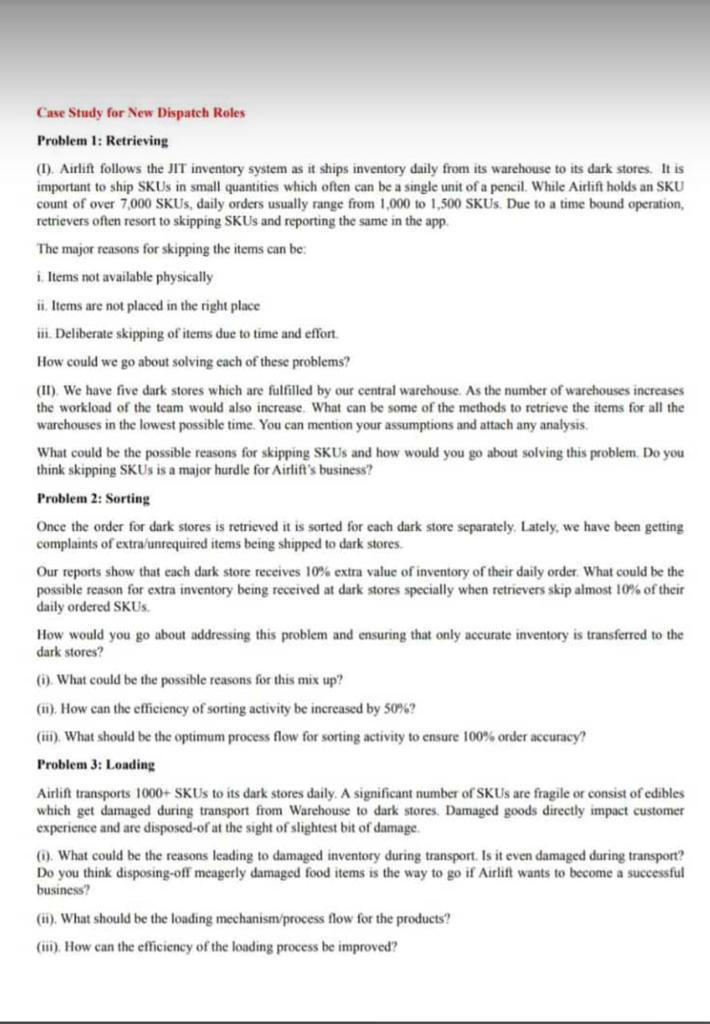

Case Study for New Dispatch Reles Problem 1: Retrieving (1). Airlift follows the IT inventory system as it ships inventory daily from its warehouse to its dark stores. It is important to ship SKUs in small quantities which often can be a single unit of a pencil. While Airlift holds an SKU count of over 7,000 SKUs, daily orders usually range from 1,000 to 1,500 SKUs. Due to a time bound operation, retrievers often resort to skipping SKUs and reporting the same in the app The major reasons for skipping the items can be i. Items not available physically it. Items are not placed in the right place 111. Deliberate skipping of items due to time and effort. How could we go about solving each of these problems? (II). We have five dark stores which are fulfilled by our central warehouse. As the number of warehouses increases the workload of the team would also increase. What can be some of the methods to retrieve the items for all the warehouses in the lowest possible time. You can mention your assumptions and attach any analysis What could be the possible reasons for skipping SKUs and how would you go about solving this problem. Do you think skipping SKUs is a major hurdle for Airlift's business? Problem 2: Sorting Once the order for dark stores is retrieved it is sorted for each dark store separately. Lately, we have been getting complaints of extra/unrequired items being shipped to dark stores Our reports show that each dark store receives 10% extra value of inventory of their daily order. What could be the possible reason for extra inventory being received at dark stores specially when retrievers skip almost 10% of their daily ordered SKUS How would you go about addressing this problem and ensuring that only accurate inventory is transferred to the dark stores? (1). What could be the possible reasons for this mix up? (n). How can the efficiency of sorting activity be increased by 50%? (i). What should be the optimum process flow for sorting activity to ensure 100% order accuracy? Problem 3: Loading Airlift transports 1000+ SKUs to its dark stores daily. A significant number of SKUs are fragile or consist of edibles which get damaged during transport from Warehouse to dark stores. Damaged goods directly impact customer experience and are disposed-of at the sight of slightest bit of damage (1). What could be the reasons leading to damaged inventory during transport. Is it even damaged during transport? Do you think disposing-off meagerly damaged food items is the way to go if Airlift wants to become a successful business? (11). What should be the loading mechanism/process flow for the products? (in). How can the efficiency of the loading process be improved? Case Study for New Dispatch Reles Problem 1: Retrieving (1). Airlift follows the IT inventory system as it ships inventory daily from its warehouse to its dark stores. It is important to ship SKUs in small quantities which often can be a single unit of a pencil. While Airlift holds an SKU count of over 7,000 SKUs, daily orders usually range from 1,000 to 1,500 SKUs. Due to a time bound operation, retrievers often resort to skipping SKUs and reporting the same in the app The major reasons for skipping the items can be i. Items not available physically it. Items are not placed in the right place 111. Deliberate skipping of items due to time and effort. How could we go about solving each of these problems? (II). We have five dark stores which are fulfilled by our central warehouse. As the number of warehouses increases the workload of the team would also increase. What can be some of the methods to retrieve the items for all the warehouses in the lowest possible time. You can mention your assumptions and attach any analysis What could be the possible reasons for skipping SKUs and how would you go about solving this problem. Do you think skipping SKUs is a major hurdle for Airlift's business? Problem 2: Sorting Once the order for dark stores is retrieved it is sorted for each dark store separately. Lately, we have been getting complaints of extra/unrequired items being shipped to dark stores Our reports show that each dark store receives 10% extra value of inventory of their daily order. What could be the possible reason for extra inventory being received at dark stores specially when retrievers skip almost 10% of their daily ordered SKUS How would you go about addressing this problem and ensuring that only accurate inventory is transferred to the dark stores? (1). What could be the possible reasons for this mix up? (n). How can the efficiency of sorting activity be increased by 50%? (i). What should be the optimum process flow for sorting activity to ensure 100% order accuracy? Problem 3: Loading Airlift transports 1000+ SKUs to its dark stores daily. A significant number of SKUs are fragile or consist of edibles which get damaged during transport from Warehouse to dark stores. Damaged goods directly impact customer experience and are disposed-of at the sight of slightest bit of damage (1). What could be the reasons leading to damaged inventory during transport. Is it even damaged during transport? Do you think disposing-off meagerly damaged food items is the way to go if Airlift wants to become a successful business? (11). What should be the loading mechanism/process flow for the products? (in). How can the efficiency of the loading process be improvedStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock