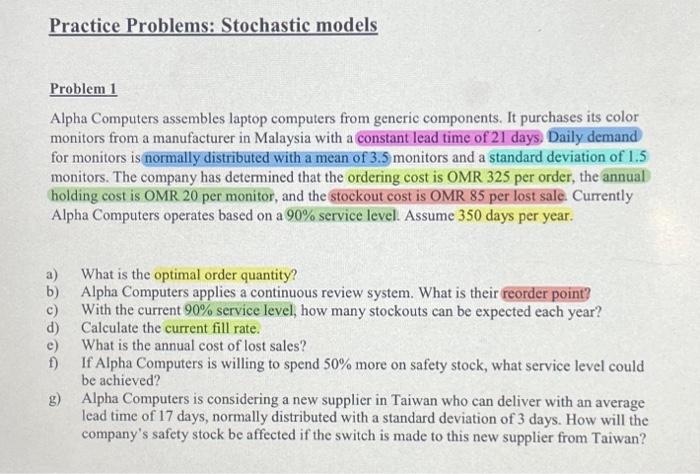

Question: Practice Problems: Stochastic models Problem 1 Alpha Computers assembles laptop computers from generic components. It purchases its color monitors from a manufacturer in Malaysia with

Problem 1 Alpha Computers assembles laptop computers from generic components. It purchases its color monitors from a manufacturer in Malaysia with a constant lead time of 21 days. Daily demand for monitors is normally distributed with a mean of 3.5 monitors and a standard deviation of 1.5 monitors. The company has determined that the ordering cost is OMR 325 per order, the annual holding cost is OMR 20 per monitor, and the stockout cost is OMR 85 per lost sale. Currently Alpha Computers operates based on a 90% service level. Assume 350 days per year. a) What is the optimal order quantity? b) Alpha Computers applies a continuous review system. What is their reorder point? c) With the current 90% service level, how many stockouts can be expected each year? d) Calculate the current fill rate. e) What is the annual cost of lost sales? f) If Alpha Computers is willing to spend 50% more on safety stock, what service level could be achieved? g) Alpha Computers is considering a new supplier in Taiwan who can deliver with an average lead time of 17 days, normally distributed with a standard deviation of 3 days. How will the company's safety stock be affected if the switch is made to this new supplier from Taiwan

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts