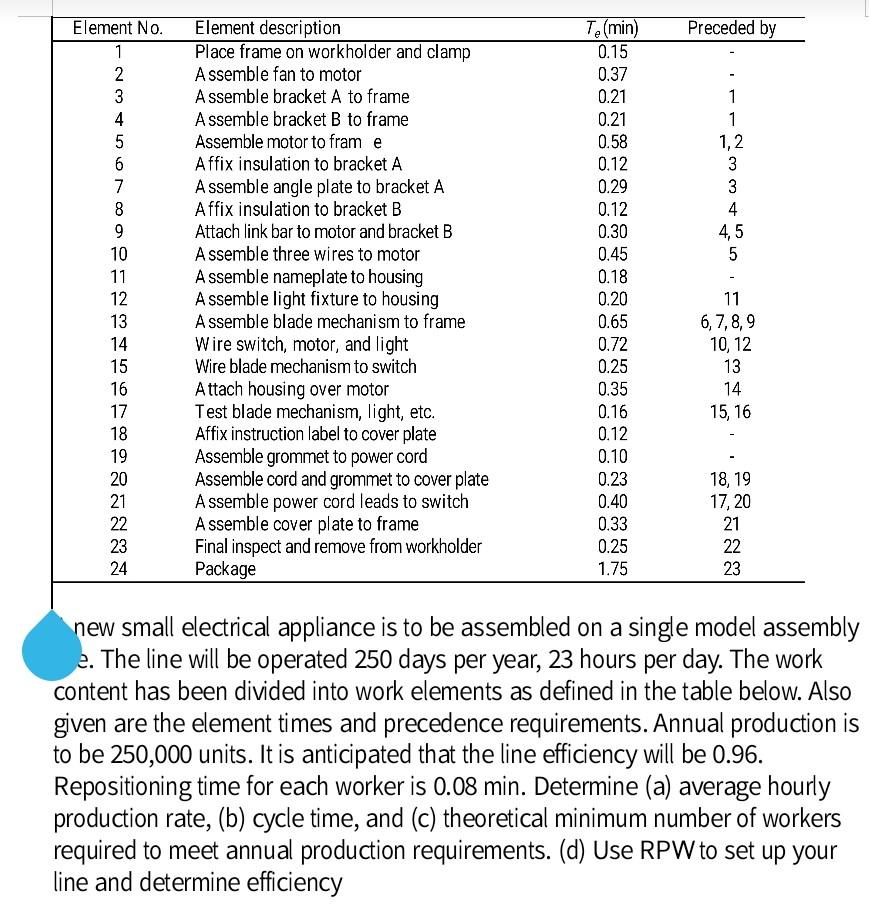

Question: Preceded by Element No. 1 2 3 4 5 6 7 8 9 NON 1 1 1,2 3 3 4 4,5 5 10 11 12

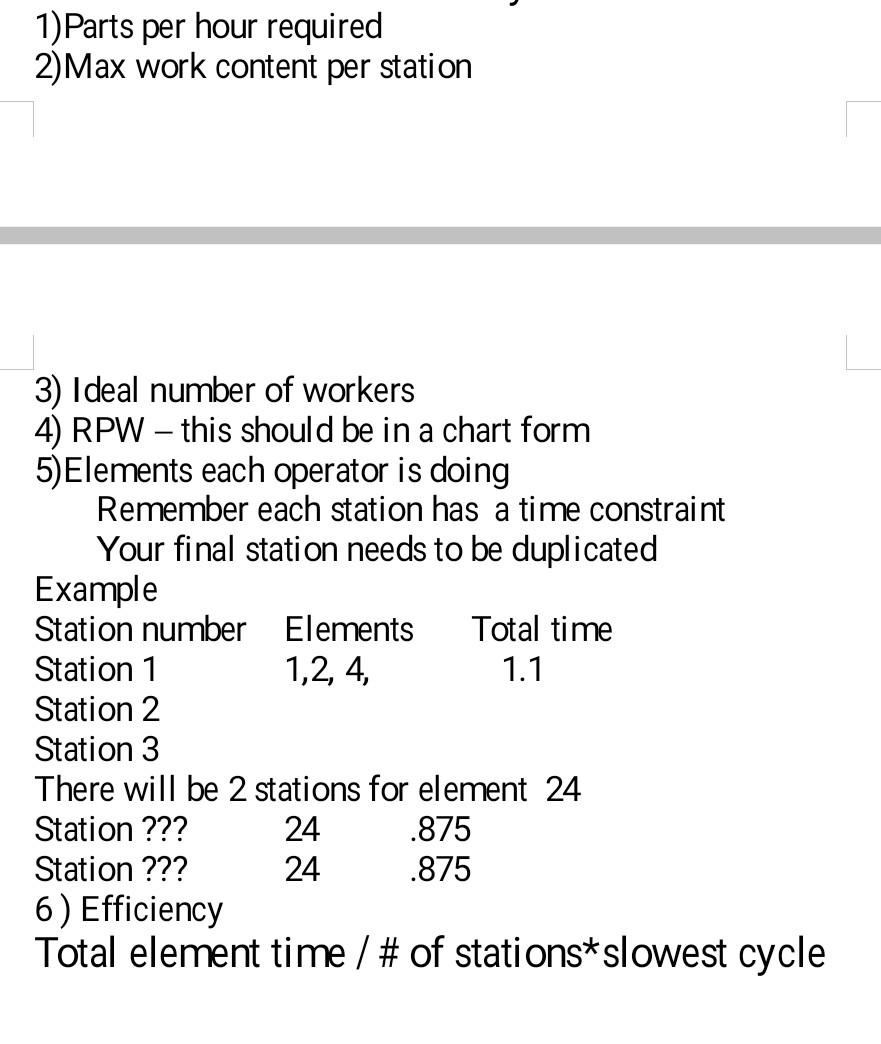

Preceded by Element No. 1 2 3 4 5 6 7 8 9 NON 1 1 1,2 3 3 4 4,5 5 10 11 12 Element description Place frame on workholder and clamp Assemble fan to motor Assemble bracket A to frame Assemble bracket B to frame Assemble motor to frame Affix insulation to bracket A Assemble angle plate to bracket A Affix insulation to bracket B Attach link bar to motor and bracket B Assemble three wires to motor Assemble nameplate to housing Assemble light fixture to housing Assemble blade mechanism to frame Wire switch, motor, and light Wire blade mechanism to switch Attach housing over motor Test blade mechanism, light, etc. Affix instruction label to cover plate Assemble grommet to power cord Assemble cord and grommet to cover plate Assemble power cord leads to switch Assemble cover plate to frame Final inspect and remove from workholder Package Te (min) 0.15 0.37 0.21 0.21 0.58 0.12 0.29 0.12 0.30 0.45 0.18 0.20 0.65 0.72 0.25 0.35 0.16 0.12 0.10 0.23 0.40 0.33 0.25 1.75 11 6,7,8,9 10,12 13 14 15, 16 13 14 15 16 17 18 19 20 21 22 23 24 18, 19 17,20 21 22 23 new small electrical appliance is to be assembled on a single model assembly e. The line will be operated 250 days per year, 23 hours per day. The work content has been divided into work elements as defined in the table below. Also given are the element times and precedence requirements. Annual production is to be 250,000 units. It is anticipated that the line efficiency will be 0.96. Repositioning time for each worker is 0.08 min. Determine (a) average hourly production rate, (b) cycle time, and (c) theoretical minimum number of workers required to meet annual production requirements. (d) Use RPW to set up your line and determine efficiency 1) Parts per hour required 2)Max work content per station 3) Ideal number of workers 4) RPW this should be in a chart form 5)Elements each operator is doing Remember each station has a time constraint Your final station needs to be duplicated Example Station number Elements Total time Station 1 1,2, 4, 1.1 Station 2 Station 3 There will be 2 stations for element 24 Station ??? 24 .875 Station ??? .875 6) Efficiency Total element time / # of stations* slowest cycle 24 Preceded by Element No. 1 2 3 4 5 6 7 8 9 NON 1 1 1,2 3 3 4 4,5 5 10 11 12 Element description Place frame on workholder and clamp Assemble fan to motor Assemble bracket A to frame Assemble bracket B to frame Assemble motor to frame Affix insulation to bracket A Assemble angle plate to bracket A Affix insulation to bracket B Attach link bar to motor and bracket B Assemble three wires to motor Assemble nameplate to housing Assemble light fixture to housing Assemble blade mechanism to frame Wire switch, motor, and light Wire blade mechanism to switch Attach housing over motor Test blade mechanism, light, etc. Affix instruction label to cover plate Assemble grommet to power cord Assemble cord and grommet to cover plate Assemble power cord leads to switch Assemble cover plate to frame Final inspect and remove from workholder Package Te (min) 0.15 0.37 0.21 0.21 0.58 0.12 0.29 0.12 0.30 0.45 0.18 0.20 0.65 0.72 0.25 0.35 0.16 0.12 0.10 0.23 0.40 0.33 0.25 1.75 11 6,7,8,9 10,12 13 14 15, 16 13 14 15 16 17 18 19 20 21 22 23 24 18, 19 17,20 21 22 23 new small electrical appliance is to be assembled on a single model assembly e. The line will be operated 250 days per year, 23 hours per day. The work content has been divided into work elements as defined in the table below. Also given are the element times and precedence requirements. Annual production is to be 250,000 units. It is anticipated that the line efficiency will be 0.96. Repositioning time for each worker is 0.08 min. Determine (a) average hourly production rate, (b) cycle time, and (c) theoretical minimum number of workers required to meet annual production requirements. (d) Use RPW to set up your line and determine efficiency 1) Parts per hour required 2)Max work content per station 3) Ideal number of workers 4) RPW this should be in a chart form 5)Elements each operator is doing Remember each station has a time constraint Your final station needs to be duplicated Example Station number Elements Total time Station 1 1,2, 4, 1.1 Station 2 Station 3 There will be 2 stations for element 24 Station ??? 24 .875 Station ??? .875 6) Efficiency Total element time / # of stations* slowest cycle 24

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts