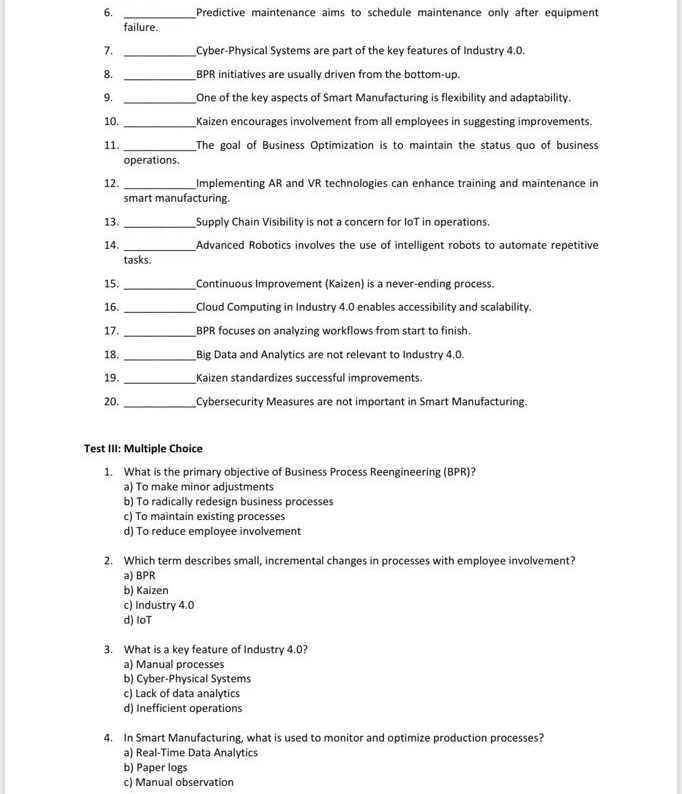

Question: Predictive maintenance aims to schedule maintenance only after equipment failure. Cyber - Physical Systems are part of the key features of Industry 4 . 0

Predictive maintenance aims to schedule maintenance only after equipment failure.

CyberPhysical Systems are part of the key features of Industry

BPR initiatives are usually driven from the bottomup

One of the key aspects of Smart Manufacturing is flexibility and adaptability.

Kaizen encourages involvement from all employees in suggesting improvements.

The goal of Business Optimization is to maintain the status quo of business operations.

Implementing AR and VR technologies can enhance training and maintenance in smart manufacturing.

Supply Chain Visibility is not a concern for loT in operations.

Advanced Robotics involves the use of intelligent robots to automate repetitive tasks.

Continuous Improvement Kaizen is a neverending process.

Cloud Computing in Industry enables accessibility and scalability.

BPR focuses on analyzing workflows from start to finish.

Big Data and Analytics are not relevant to Industry

Kaizen standardizes successful improvements.

Cybersecurity Measures are not important in Smart Manufacturing.

Test III: Multiple Choice

What is the primary objective of Business Process Reengineering BPR

a To make minor adjustments

b To radically redesign business processes

c To maintain existing processes

d To reduce employee involvement

Which term describes small, incremental changes in processes with employee involvement?

a BPR

b Kaizen

c Industry

d loT

What is a key feature of Industry

a Manual processes

b CyberPhysical Systems

c Lack of data analytics

d Inefficient operations

In Smart Manufacturing, what is used to monitor and optimize production processes?

a RealTime Data Analytics

b Paper logs

c Manual observation

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock