Question: Preventive Maintenance Procedure Assignment Scenario - Based on assignment 1 0 - 2 in Fluid Power Systems A hydraulic system with a water - cooled

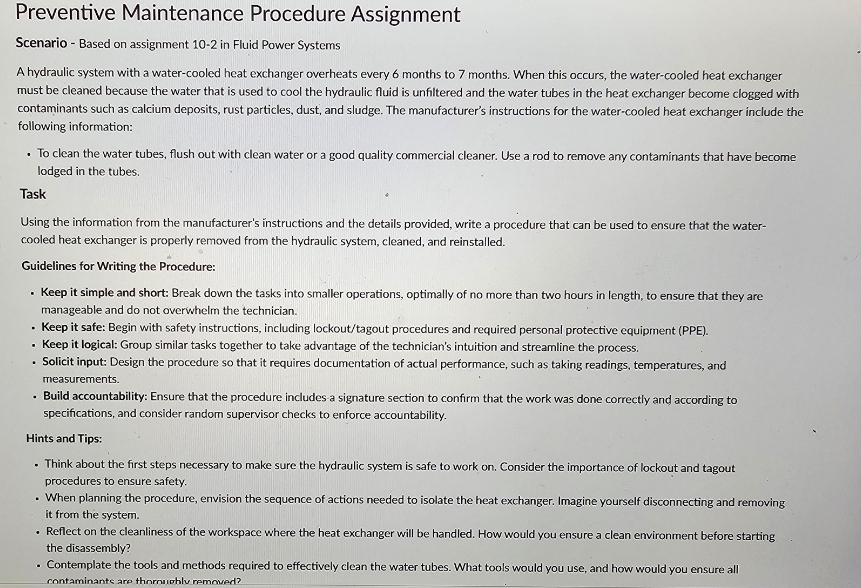

Preventive Maintenance Procedure Assignment

Scenario Based on assignment in Fluid Power Systems

A hydraulic system with a watercooled heat exchanger overheats every months to months. When this occurs, the watercooled heat exchanger must be cleaned because the water that is used to cool the hydraulic fluid is unfiltered and the water tubes in the heat exchanger become clogged with contaminants such as calcium deposits, rust particles, dust, and sludge. The manufacturer's instructions for the watercooled heat exchanger include the following information:

To clean the water tubes, flush out with clean water or a good quality commercial cleaner. Use a rod to remove any contaminants that have become lodged in the tubes.

Task

Using the information from the manufacturer's instructions and the details provided, write a procedure that can be used to ensure that the watercooled heat exchanger is properly removed from the hydraulic system, cleaned, and reinstalled.

Guidelines for Writing the Procedure:

Keep it simple and short: Break down the tasks into smaller operations, optimally of no more than two hours in length, to ensure that they are manageable and do not overwhelm the technician.

Keep it safe: Begin with safety instructions, including lockouttagout procedures and required personal protective equipment PPE

Keep it logical: Group similar tasks together to take advantage of the technician's intuition and streamline the process.

Solicit input: Design the procedure so that it requires documentation of actual performance, such as taking readings, temperatures, and measurements.

Build accountability: Ensure that the procedure includes a signature section to confirm that the work was done correctly and according to specifications, and consider random supervisor checks to enforce accountability.

Hints and Tips:

Think about the first steps necessary to make sure the hydraulic system is safe to work on Consider the importance of lockout and tagout procedures to ensure safety.

When planning the procedure, envision the sequence of actions needed to isolate the heat exchanger. Imagine yourself disconnecting and removing it from the system.

Reflect on the cleanliness of the workspace where the heat exchanger will be handled. How would you ensure a clean environment before starting the disassembly?

Contemplate the tools and methods required to effectively clean the water tubes. What tools would you use, and how would you ensure all

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock