Question: Prior to making a polymer solution for coating plastic film, a solvent is pumped into a jacketed, carbon steel, Teflon-lined vessel that is 3 m

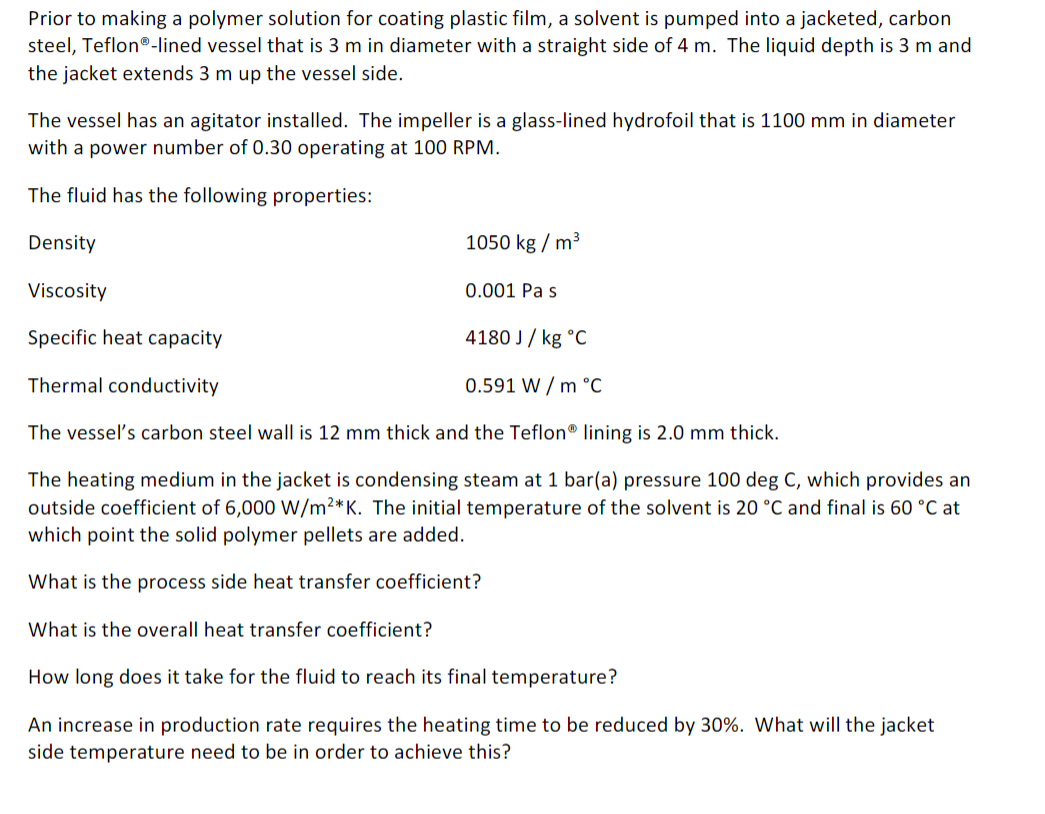

Prior to making a polymer solution for coating plastic film, a solvent is pumped into a jacketed, carbon steel, Teflon-lined vessel that is 3 m in diameter with a straight side of 4 m. The liquid depth is 3 m and the jacket extends 3 m up the vessel side. The vessel has an agitator installed. The impeller is a glass-lined hydrofoil that is 1100 mm in diameter with a power number of 0.30 operating at 100 RPM. The fluid has the following properties: Density 1050 kg / m3 Viscosity 0.001 Pas Specific heat capacity 4180 J/kg C Thermal conductivity 0.591 W/m C The vessel's carbon steel wall is 12 mm thick and the Teflon lining is 2.0 mm thick. The heating medium in the jacket is condensing steam at 1 bar(a) pressure 100 deg C, which provides an outside coefficient of 6,000 W/m2*K. The initial temperature of the solvent is 20 C and final is 60 C at which point the solid polymer pellets are added. What is the process side heat transfer coefficient? What is the overall heat transfer coefficient? How long does it take for the fluid to reach its final temperature? An increase in production rate requires the heating time to be reduced by 30%. What will the jacket side temperature need to be in order to achieve this

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts