Question: Problem #1 [40 pts] For the shown worm-gear set (figure 1), the designer is proposing to change the type of bearings used for supporting the

![Problem #1 [40 pts] For the shown worm-gear set (figure 1),](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2024/10/66fe501f1f165_68666fe501e75ce8.jpg)

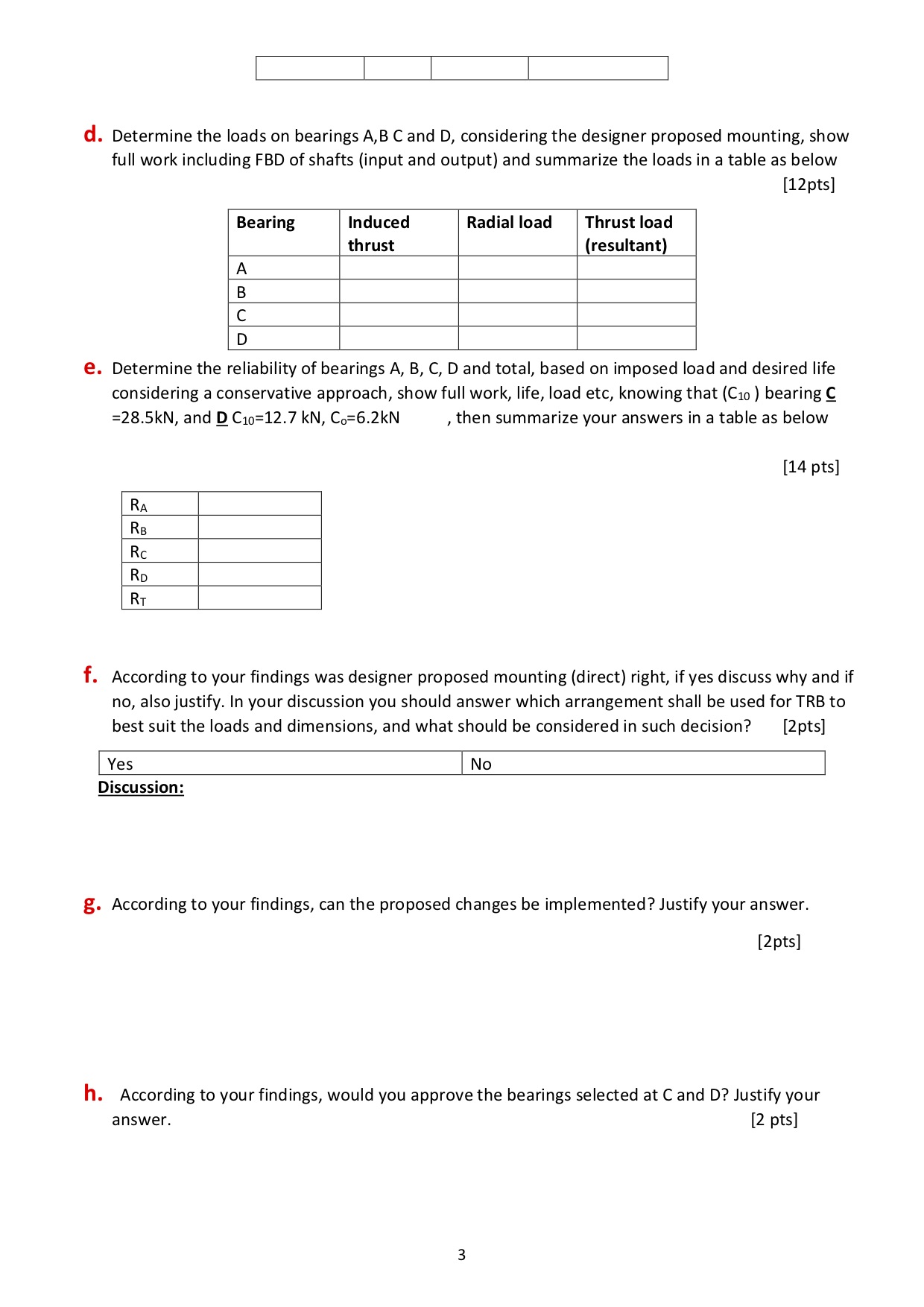

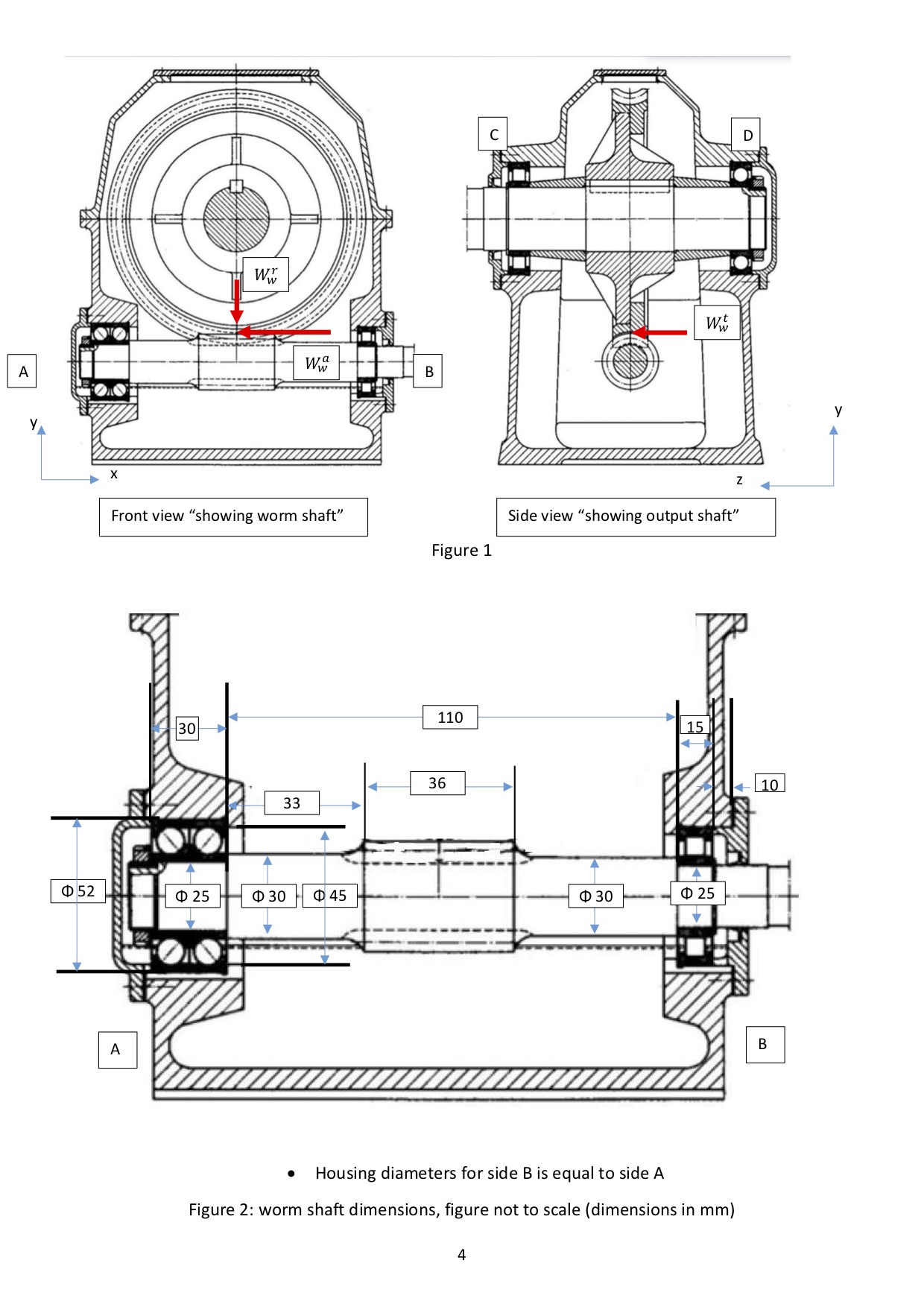

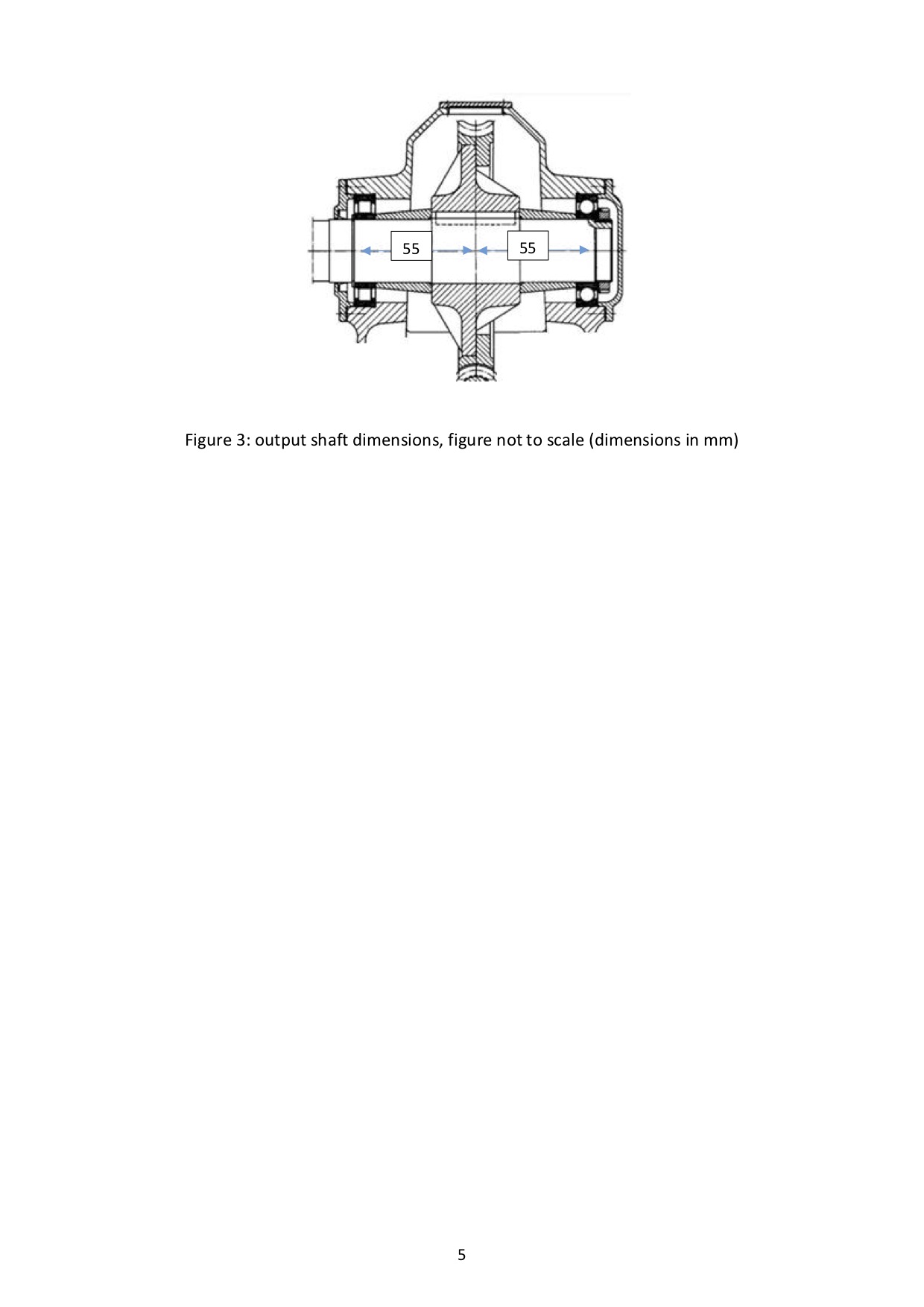

Problem #1 [40 pts] For the shown worm-gear set (figure 1), the designer is proposing to change the type of bearings used for supporting the worm shaft to two identical tapered roller bearings; without changing any of shaft or enclosure dimensions. The commercial worm gear set is used in machine that is fully utilized over 8hr shift. The desired over all reliability of bearings (all four) used on the commercial gearbox is 97%. The following specification (table 1) of the worm-gear set are given to you to perform a review and assess the proposed changes. The designer has suggested to replace the bearings on worm shaft with two identical TRB cone and cup number 33205, he is suggesting to use them in a direct mounting arrangement. Answer the following questions in order to provide a final decision on proposed changes and assessment of the 4 bearings. Table 1 Unit mm symbol dw da mm value 31 120 341 60 2T 17.5 o Deg. mm Deg. Element worm diameter Worm-gear diameter Worm lead angle Worm axial pitch Normal pressure angle Number of starts Number of teeth on gear Input speed Output speed Thrust load (on worm) Radial load (on worm) Tangential load (on worm) n Nw NG 1 60 nw 1800 30 ng Wo rpm rpm N N N 1130 358.6 73 WW W! a. What type of bearings are used in the original design for the worm shaft and the output shaft? present your answers in a table as below [2pt] B C D Bearing Type b. At side A, how is this arrangement called? [2pts] C. For the proposed TRB cone and cup number 33205 (Fig. 11-15, textbook), perform a dimensional assessment to see if space limitation would allow installing the TRB. Do a full assessment in a table as below, not only based on bore size as it is made ready for you. [4pts] Dimension Size Evaluation Available space 25 Bore 25 Satisfactory 2 d. Determine the loads on bearings A, B C and D, considering the designer proposed mounting, show full work including FBD of shafts (input and output) and summarize the loads in a table as below [12pts] Bearing Radial load Induced thrust Thrust load (resultant) A B D e. Determine the reliability of bearings A, B, C, D and total, based on imposed load and desired life considering a conservative approach, show full work, life, load etc, knowing that (C10 ) bearing C =28.5kN, and D C10=12.7 kN, Co=6.2kN then summarize your answers in a table as below (14 pts) RA RB Rc RD RT f. According to your findings was designer proposed mounting (direct) right, if yes discuss why and if no, also justify. In your discussion you should answer which arrangement shall be used for TRB to best suit the loads and dimensions, and what should be considered in such decision? [2pts] No Yes Discussion: g. According to your findings, can the proposed changes be implemented? Justify your answer. [2pts] h. According to your findings, would you approve the bearings selected at C and D? Justify your [2 pts] answer. 3 C D W Winte w A B Z Front view showing worm shaft" Side view "showing output shaft" Figure 1 P 110 30 15 36 + 10 33 0 52 25 30 045 30 25 A B Housing diameters for side B is equal to side A Figure 2: worm shaft dimensions, figure not to scale (dimensions in mm) 4 55 55 Figure 3: output shaft dimensions, figure not to scale (dimensions in mm) 5 Problem #1 [40 pts] For the shown worm-gear set (figure 1), the designer is proposing to change the type of bearings used for supporting the worm shaft to two identical tapered roller bearings; without changing any of shaft or enclosure dimensions. The commercial worm gear set is used in machine that is fully utilized over 8hr shift. The desired over all reliability of bearings (all four) used on the commercial gearbox is 97%. The following specification (table 1) of the worm-gear set are given to you to perform a review and assess the proposed changes. The designer has suggested to replace the bearings on worm shaft with two identical TRB cone and cup number 33205, he is suggesting to use them in a direct mounting arrangement. Answer the following questions in order to provide a final decision on proposed changes and assessment of the 4 bearings. Table 1 Unit mm symbol dw da mm value 31 120 341 60 2T 17.5 o Deg. mm Deg. Element worm diameter Worm-gear diameter Worm lead angle Worm axial pitch Normal pressure angle Number of starts Number of teeth on gear Input speed Output speed Thrust load (on worm) Radial load (on worm) Tangential load (on worm) n Nw NG 1 60 nw 1800 30 ng Wo rpm rpm N N N 1130 358.6 73 WW W! a. What type of bearings are used in the original design for the worm shaft and the output shaft? present your answers in a table as below [2pt] B C D Bearing Type b. At side A, how is this arrangement called? [2pts] C. For the proposed TRB cone and cup number 33205 (Fig. 11-15, textbook), perform a dimensional assessment to see if space limitation would allow installing the TRB. Do a full assessment in a table as below, not only based on bore size as it is made ready for you. [4pts] Dimension Size Evaluation Available space 25 Bore 25 Satisfactory 2 d. Determine the loads on bearings A, B C and D, considering the designer proposed mounting, show full work including FBD of shafts (input and output) and summarize the loads in a table as below [12pts] Bearing Radial load Induced thrust Thrust load (resultant) A B D e. Determine the reliability of bearings A, B, C, D and total, based on imposed load and desired life considering a conservative approach, show full work, life, load etc, knowing that (C10 ) bearing C =28.5kN, and D C10=12.7 kN, Co=6.2kN then summarize your answers in a table as below (14 pts) RA RB Rc RD RT f. According to your findings was designer proposed mounting (direct) right, if yes discuss why and if no, also justify. In your discussion you should answer which arrangement shall be used for TRB to best suit the loads and dimensions, and what should be considered in such decision? [2pts] No Yes Discussion: g. According to your findings, can the proposed changes be implemented? Justify your answer. [2pts] h. According to your findings, would you approve the bearings selected at C and D? Justify your [2 pts] answer. 3 C D W Winte w A B Z Front view showing worm shaft" Side view "showing output shaft" Figure 1 P 110 30 15 36 + 10 33 0 52 25 30 045 30 25 A B Housing diameters for side B is equal to side A Figure 2: worm shaft dimensions, figure not to scale (dimensions in mm) 4 55 55 Figure 3: output shaft dimensions, figure not to scale (dimensions in mm) 5

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts