Question: PROBLEM 1 . 6 0 pts The End Connector ( Fig . 1 ) is machined on a CNC system using carbide tools. Turning: 1

PROBLEM pts

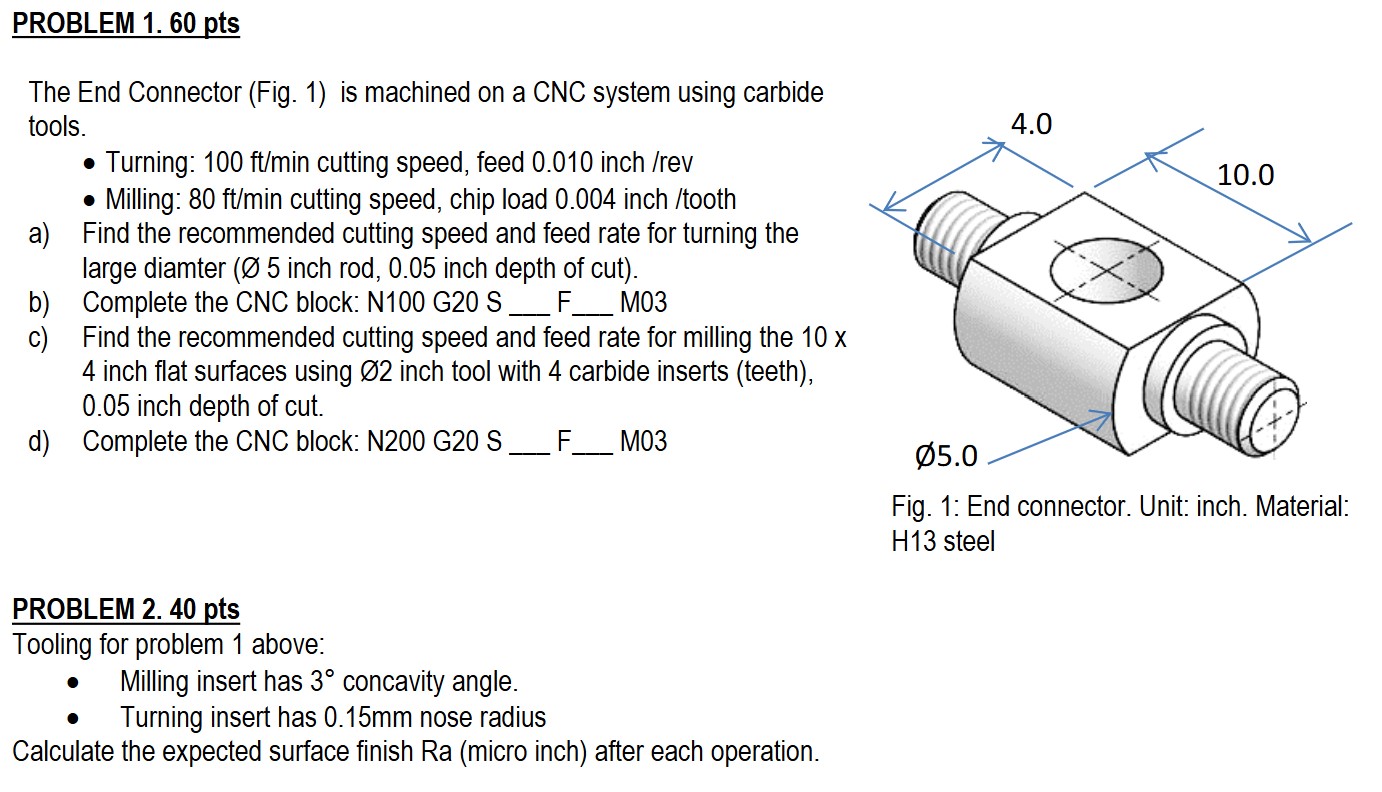

The End Connector Fig is machined on a CNC system using carbide

tools.

Turning: ftmin cutting speed, feed inch rev

Milling: ftmin cutting speed, chip load inch tooth

a Find the recommended cutting speed and feed rate for turning the

large diamter O inch rod, inch depth of cut

b Complete the CNC block: N G S

F

M

c Find the recommended cutting speed and feed rate for milling the x

inch flat surfaces using O inch tool with carbide inserts teeth

inch depth of cut.

d Complete the CNC block: N G S

F

M

Fig. : End connector. Unit: inch. Material:

H steel

PROBLEM pts

Tooling for problem above:

Milling insert has @ concavity angle.

Turning insert has mm nose radius

Calculate the expected surface finish Ra micro inch after each operation.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock