Question: Problem 1 . A part is manufactured using a 'non - stick' mold, but yield is unacceptably low due to part adhesion to the mold

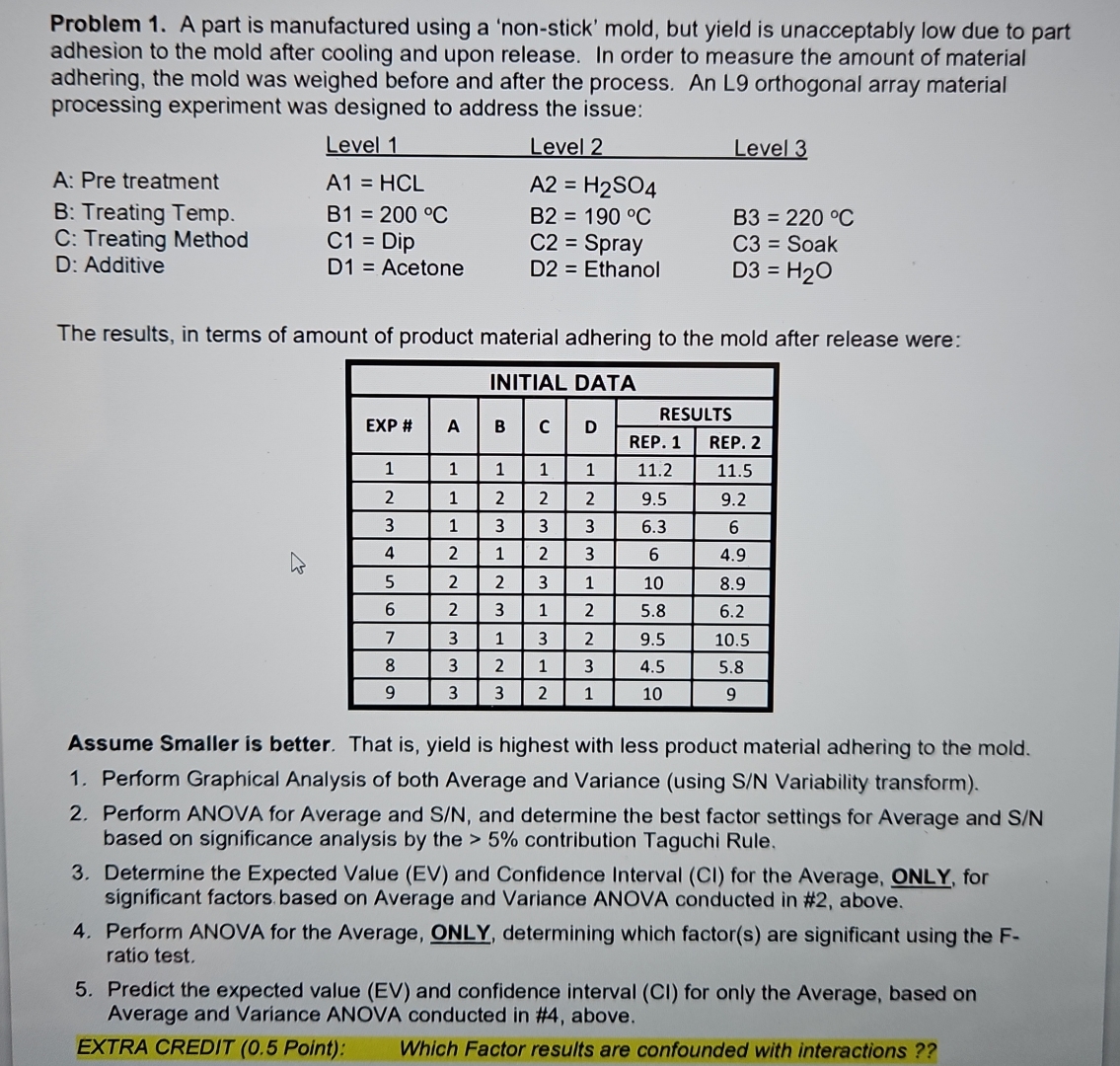

Problem A part is manufactured using a 'nonstick' mold, but yield is unacceptably low due to part adhesion to the mold after cooling and upon release. In order to measure the amount of material adhering, the mold was weighed before and after the process. An L orthogonal array material processing experiment was designed to address the issue:

A: Pre treatment

Level

Level

Level

B: Treating Temp.

C: Treating Method

D: Additive

C Dip

Spray

C Soak

D Acetone

D Ethanol

D

The results, in terms of amount of product material adhering to the mold after release were:

tableINITIAL DATAEXP #ABCDRESULTS,REP. REP.

Assume Smaller is better. That is yield is highest with less product material adhering to the mold.

Perform Graphical Analysis of both Average and Variance using SN Variability transform

Perform ANOVA for Average and and determine the best factor settings for Average and based on significance analysis by the contribution Taguchi Rule,

Determine the Expected Value EV and Confidence Interval CI for the Average, ONLY, for significant factors based on Average and Variance ANOVA conducted in # above.

Perform ANOVA for the Average,

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock