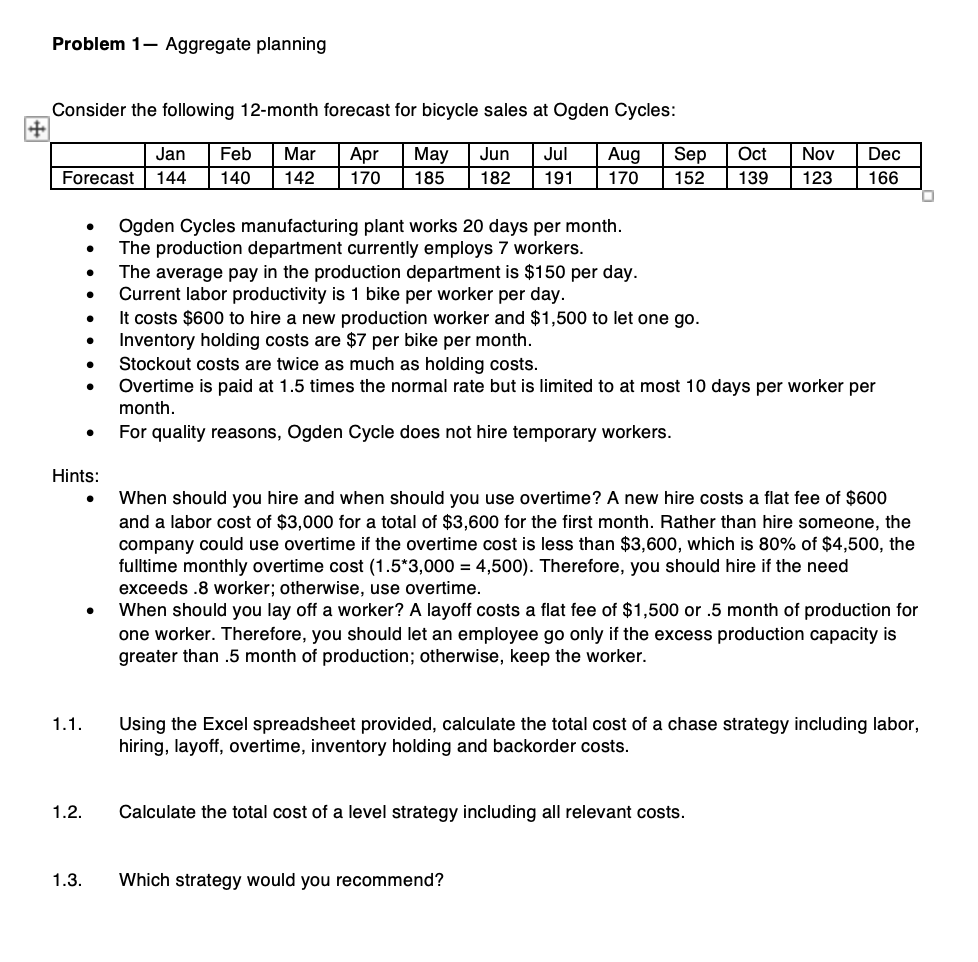

Question: Problem 1- Aggregate planning Consider the following 12-month forecast for bicycle sales at Ogden Cycles: Jan 144 Feb 140 Mar 142 Apr 170 May 185

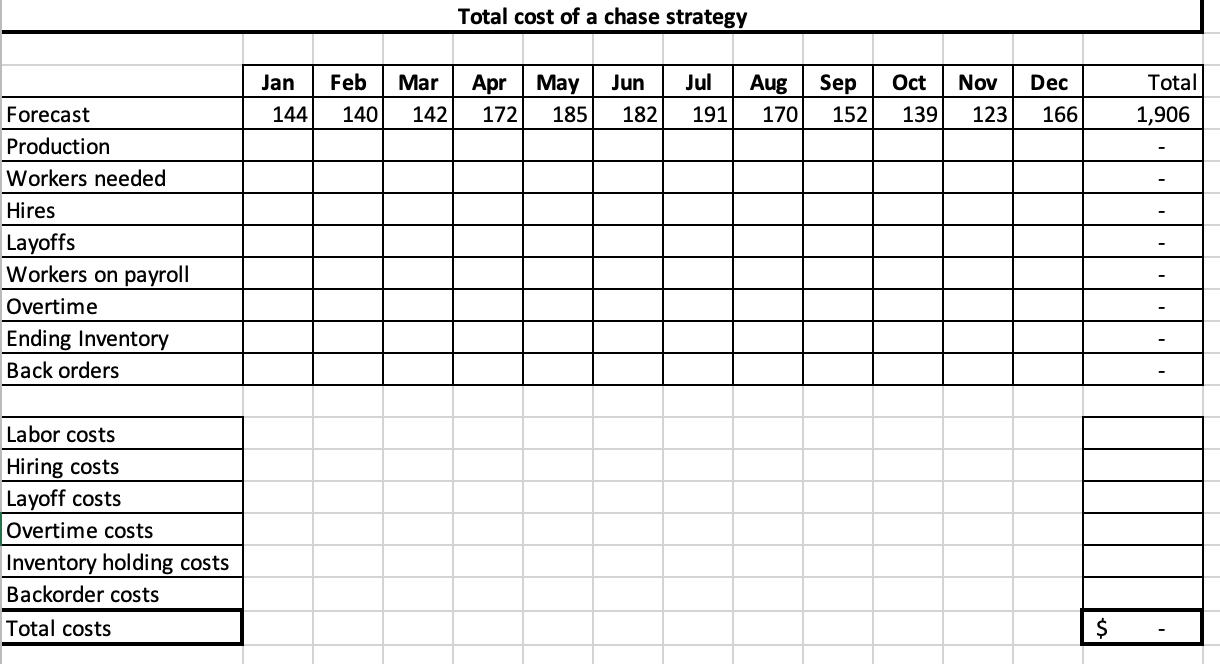

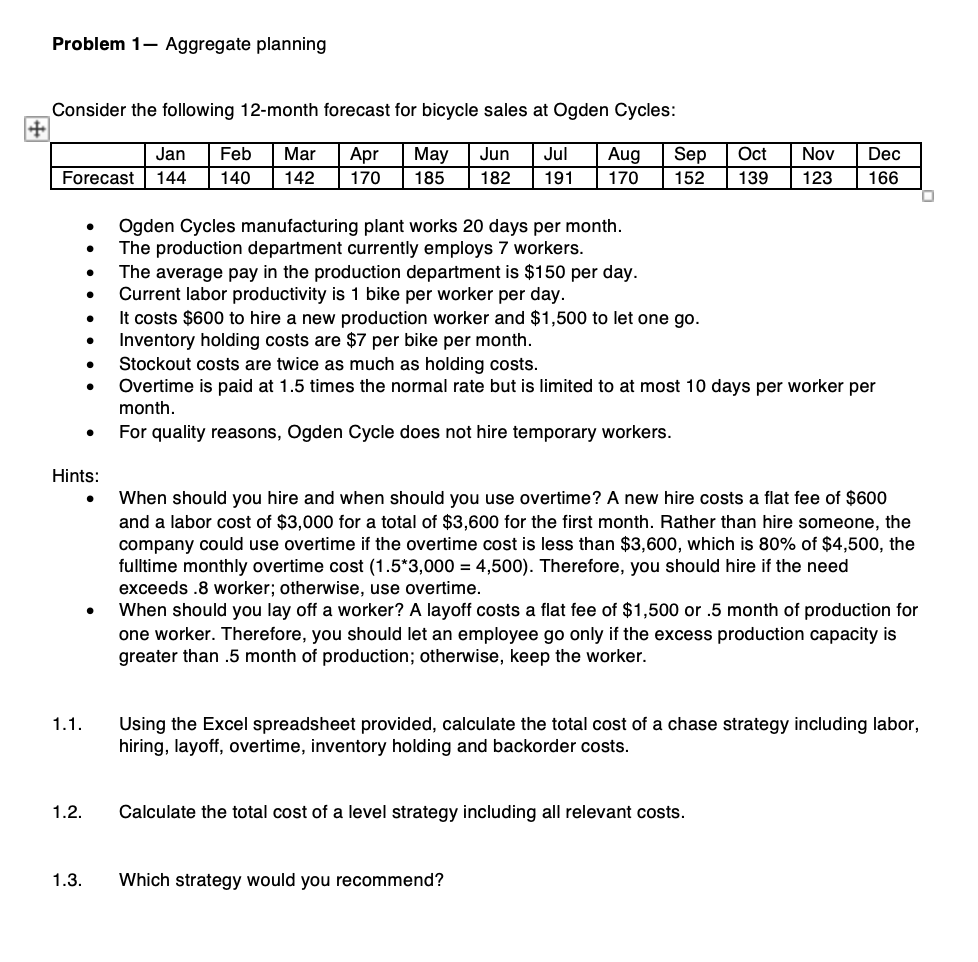

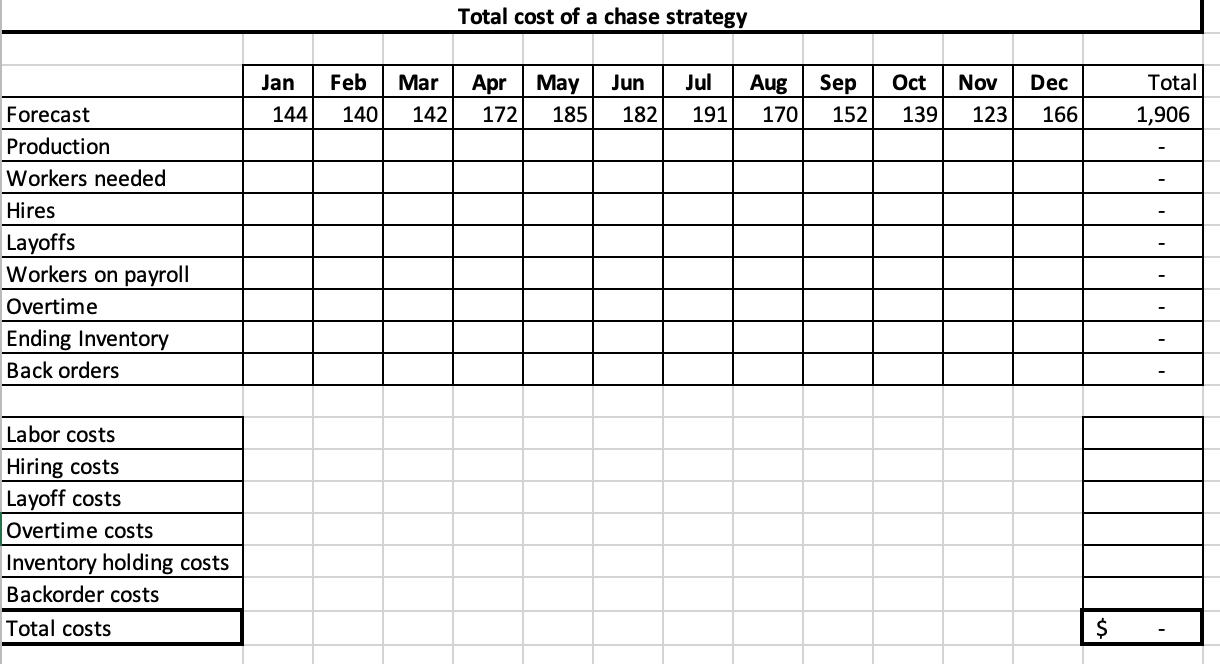

Problem 1- Aggregate planning Consider the following 12-month forecast for bicycle sales at Ogden Cycles: Jan 144 Feb 140 Mar 142 Apr 170 May 185 Jun 182 Jul 191 Aug 170 Sep 152 Oct 139 Nov 123 Dec 166 Forecast Ogden Cycles manufacturing plant works 20 days per month. The production department currently employs 7 workers. The average pay in the production department is $150 per day. Current labor productivity is 1 bike per worker per day. It costs $600 to hire a new production worker and $1,500 to let one go. Inventory holding costs are $7 per bike per month. Stockout costs are twice as much as holding costs. Overtime is paid at 1.5 times the normal rate but is limited to at most 10 days per worker per month. For quality reasons, Ogden Cycle does not hire temporary workers. . . Hints: When should you hire and when should you use overtime? A new hire costs a flat fee of $600 and a labor cost of $3,000 for a total of $3,600 for the first month. Rather than hire someone, the company could use overtime if the overtime cost is less than $3,600, which is 80% of $4,500, the fulltime monthly overtime cost (1.5*3,000 = 4,500). Therefore, you should hire if the need exceeds .8 worker; otherwise, use overtime. When should you lay off a worker? A layoff costs a flat fee of $1,500 or .5 month of production for one worker. Therefore, you should let an employee go only if the excess production capacity is greater than .5 month of production; otherwise, keep the worker. 1.1. Using the Excel spreadsheet provided, calculate the total cost of a chase strategy including labor, hiring, layoff, overtime, inventory holding and backorder costs. 1.2. Calculate the total cost of a level strategy including all relevant costs. 1.3 Which strategy would you recommend? Total cost of a chase strategy Jun Nov Jan 144 Feb 140 Mar 142 Apr 172 May 185 Jul 191 Aug 170 Sep 152 Oct 139 Dec 166 Total 1,906 182 123 Forecast Production Workers needed Hires Layoffs Workers on payroll Overtime Ending Inventory Back orders Labor costs Hiring costs Layoff costs Overtime costs Inventory holding costs Backorder costs Total costs $ Problem 1- Aggregate planning Consider the following 12-month forecast for bicycle sales at Ogden Cycles: Jan 144 Feb 140 Mar 142 Apr 170 May 185 Jun 182 Jul 191 Aug 170 Sep 152 Oct 139 Nov 123 Dec 166 Forecast Ogden Cycles manufacturing plant works 20 days per month. The production department currently employs 7 workers. The average pay in the production department is $150 per day. Current labor productivity is 1 bike per worker per day. It costs $600 to hire a new production worker and $1,500 to let one go. Inventory holding costs are $7 per bike per month. Stockout costs are twice as much as holding costs. Overtime is paid at 1.5 times the normal rate but is limited to at most 10 days per worker per month. For quality reasons, Ogden Cycle does not hire temporary workers. . . Hints: When should you hire and when should you use overtime? A new hire costs a flat fee of $600 and a labor cost of $3,000 for a total of $3,600 for the first month. Rather than hire someone, the company could use overtime if the overtime cost is less than $3,600, which is 80% of $4,500, the fulltime monthly overtime cost (1.5*3,000 = 4,500). Therefore, you should hire if the need exceeds .8 worker; otherwise, use overtime. When should you lay off a worker? A layoff costs a flat fee of $1,500 or .5 month of production for one worker. Therefore, you should let an employee go only if the excess production capacity is greater than .5 month of production; otherwise, keep the worker. 1.1. Using the Excel spreadsheet provided, calculate the total cost of a chase strategy including labor, hiring, layoff, overtime, inventory holding and backorder costs. 1.2. Calculate the total cost of a level strategy including all relevant costs. 1.3 Which strategy would you recommend? Total cost of a chase strategy Jun Nov Jan 144 Feb 140 Mar 142 Apr 172 May 185 Jul 191 Aug 170 Sep 152 Oct 139 Dec 166 Total 1,906 182 123 Forecast Production Workers needed Hires Layoffs Workers on payroll Overtime Ending Inventory Back orders Labor costs Hiring costs Layoff costs Overtime costs Inventory holding costs Backorder costs Total costs $