Question: Problem 1 : Discrete Optimization Zoheib, a current student in Prof. Rios's class, is doing an intern at Texas Instruments and is part of the

Problem : Discrete Optimization

Zoheib, a current student in Prof. Rios's class, is doing an intern at Texas Instruments and is part of the team that is redesigning one of their newest microchips plants. Specifically, there are five main production areas: i Wafer Fabrication Wii Photolithography Piii Etching Eiv Doping D and v Testing and Packaging T

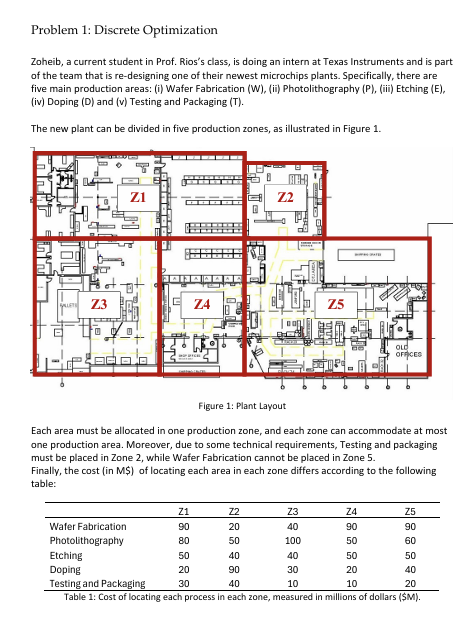

The new plant can be divided in five production zones, as illustrated in Figure

Each area must be allocated in one production zone, and each zone can accommodate at most one production area. Moreover, due to some technical requirements, Testing and packaging must be placed in Zone while Wafer Fabrication cannot be placed in Zone Finally, the cost in M$ of locating each area in each zone differs according to the following table:

begintabularlccccc

hline & Z & Z & Z & Z & Z

hline Wafer Fabrication & & & & &

Photolithography & & & & &

Etching & & & & &

Doping & & & & &

Testing and Packaging & & & & &

hline

endtabular

Table : Cost of locating each process in each zone, measured in millions of dollars $M points Build a discrete optimization model to decide the allocation of areas to production zones so as to minimize the total cost while satisfying the outlined requirements.

points Zoehib is told that, if Wafer Fabrication is located in Zone then Etching must be placed either in Zones or Update your model in part to account for this.

points Zoheib now wants to ensure that, if Wafer Fabrication is not located in Zone then it must be located in Zone Update your model in part to account for this.

points According to some estimates, placing Wafer Fabrication and Photolithography in Zones and independent of specific assignment would involve a reduction of $ mathrmM in the total cost. Update your model in part to account for this.

points Zoheib realized that his current model does not consider the transportation cost of parts within the plant. As a starting point, his boss told him to only worry about flow units going from Wafer Fabrication to Photolithology since these are the most delicate parts that involve the highest cost. To reduce the chances of contamination during the transportation process, the engineering team required that both Wafer Fabrication and Photolithology are located in Zones or Furthermore, based on last year's production in a similar plant, they estimate that M ie units will move from Wafer Fabrication to Photolithology in the next five year which is the planning horizon Finally, Zoheib estimates that the cost of moving one unit from one zone to another is given as in Table X measured in dollars. For example, moving one unit from Zone to Zone costs $ ie cents. Update your model in part to account for the transportation costs in the next five years that will result from the layout.

Table : Transportation cost for moving units from Wafer Fabrication to Photolithology depending on the zones, measured in dollars $

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock