Question: Problem 1: During a particular week employees worked 360 hours to produce a batch of 132 screens, of which 52 were seconds (meaning that they

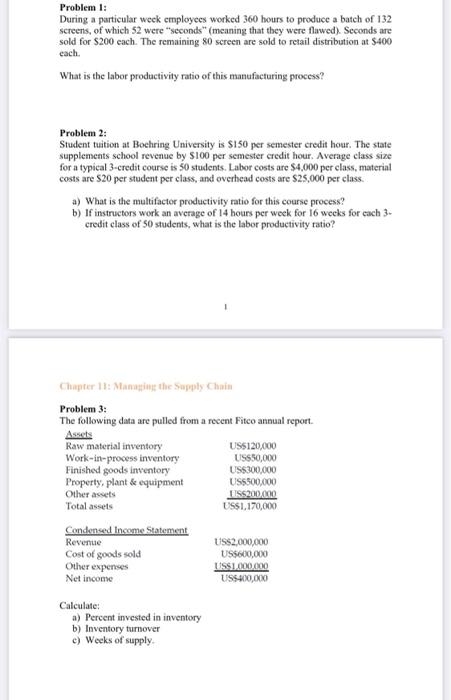

Problem 1: During a particular week employees worked 360 hours to produce a batch of 132 screens, of which 52 were "seconds" (meaning that they were flawed). Seconds are sold for $200 each. The remaining 80 screen are sold to retail distribution at $400 cach. What is the labor productivity ratio of this manufacturing process? Problem 2: Student tuition at Boehring University is $150 per semester credit hour. The state supplements school revenue by $100 per semester credit hour. Average class size for a typical 3-credit course is 50 students. Labor costs are $4.000 per class, material costs are S20 per student per class, and overhead costs are $25,000 per class. a) What is the multifactor productivity ratio for this course process? b) If instructors work an average of 14 hours per week for 16 weeks for each 3. credit class of 50 students, what is the labor productivity ratio? Chapter 11: Managing the Supply Chain Problem 3: The following data are pulled from a recent Fiteo annual report. Assets Raw material inventory US$120,000 Work-in-process inventory US$50,000 Finished goods inventory US$300,000 Property, plant & equipment US$500,000 Other assets TISS200,000 Total assets US$1,170,000 Condensed Income Statement Revenue US$2.000.000 Cost of goods sold US$600,000 Other expenses USS 1.000.000 Net income US$ 200,000 Calculate: a) Percent invested in inventory b) Inventory turnover c) Weeks of supply

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts