Question: Problem 1 (total 12 points, 3 points each) (a) A manufacturer wants to develop a new indirect sensing (soft-sensor) system for product quality inspection. Because

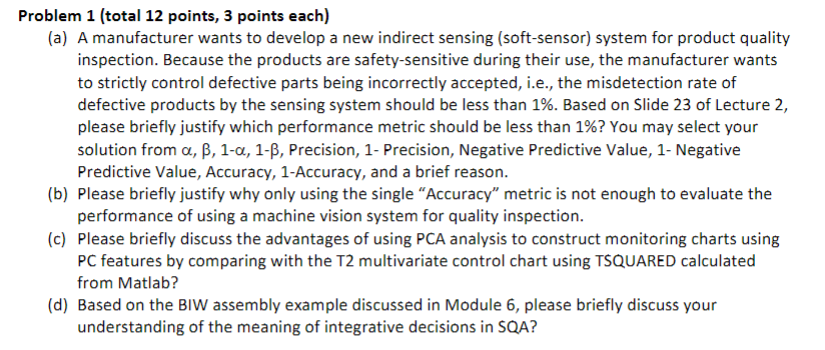

Problem 1 (total 12 points, 3 points each) (a) A manufacturer wants to develop a new indirect sensing (soft-sensor) system for product quality inspection. Because the products are safety-sensitive during their use, the manufacturer wants to strictly control defective parts being incorrectly accepted, i.e., the misdetection rate of defective products by the sensing system should be less than 1%. Based on Slide 23 of Lecture 2, please briefly justify which performance metric should be less than 1% ? You may select your solution from ,,1,1, Precision, 1- Precision, Negative Predictive Value, 1- Negative Predictive Value, Accuracy, 1-Accuracy, and a brief reason. (b) Please briefly justify why only using the single "Accuracy" metric is not enough to evaluate the performance of using a machine vision system for quality inspection. (c) Please briefly discuss the advantages of using PCA analysis to construct monitoring charts using PC features by comparing with the T2 multivariate control chart using TSQUARED calculated from Matlab? (d) Based on the BIW assembly example discussed in Module 6, please briefly discuss your understanding of the meaning of integrative decisions in SQA

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts