Question: problem 17 564 PART 3 MANAGING SUPPLY CHAINS two tables give data on capacities, forecasted demand, and shipping costs that have been gathered. For each

problem 17

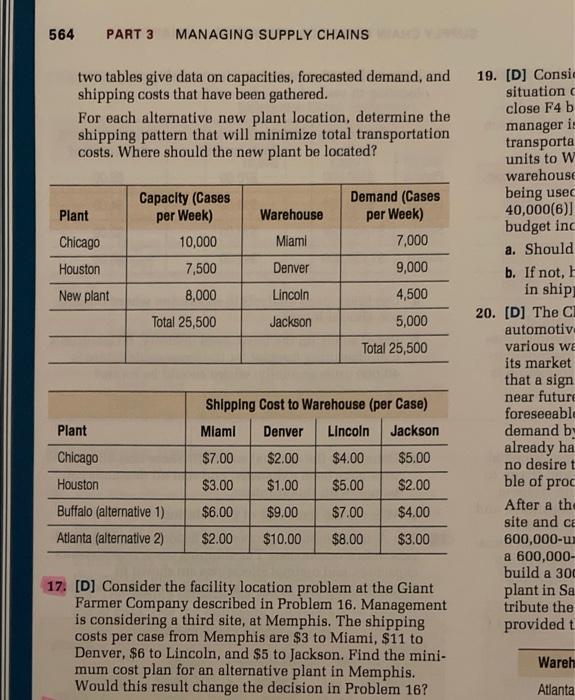

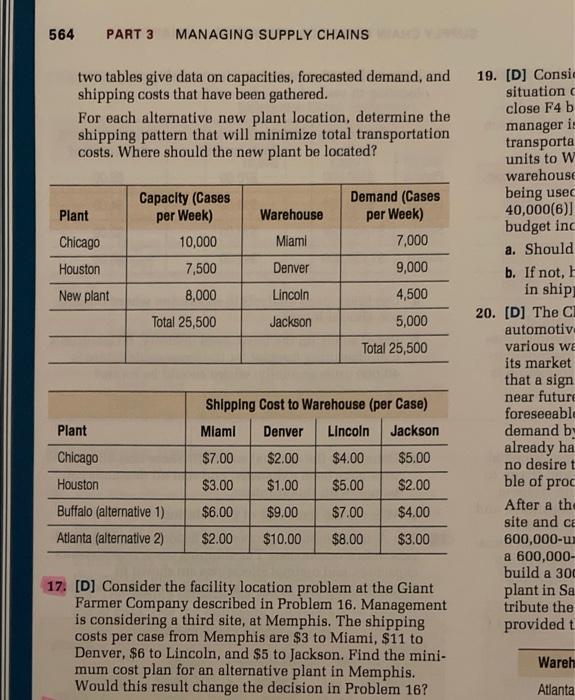

564 PART 3 MANAGING SUPPLY CHAINS two tables give data on capacities, forecasted demand, and shipping costs that have been gathered. For each alternative new plant location, determine the shipping pattern that will minimize total transportation costs. Where should the new plant be located? Plant Warehouse Capacity (Cases per Week) 10,000 7,500 8,000 Demand (Cases per Week) 7,000 Chicago Miami Houston Denver 9,000 4,500 19. [D] Consid situation close F4 b manager is transporta units to W warehouse being used 40,000(6)] budget ind a. Should b. If not, in ship? 20. [D] The C automotiv various we its market that a sign near future foreseeable demand by already ha no desiret New plant Lincoln Total 25,500 Jackson 5,000 Total 25,500 Plant Chicago Shipping Cost to Warehouse (per Case) Miami Denver Lincoln Jackson $7.00 $2.00 $4.00 $5.00 $3.00 $1.00 $5.00 $2.00 $6.00 $9.00 $7.00 $4.00 $2.00 $10.00 $8.00 $3.00 Houston ble of proc Buffalo (alternative 1) Atlanta (alternative 2) After a the site and ce 600,000-u a 600,000- build a 300 plant in Sa tribute the provided t 17. [DJ Consider the facility location problem at the Giant Farmer Company described in Problem 16. Management is considering a third site, at Memphis. The shipping costs per case from Memphis are $3 to Miami, $11 to Denver, $6 to Lincoln, and $5 to Jackson. Find the mini- mum cost plan for an alternative plant in Memphis. Would this result change the decision in Problem 16? Wareh Atlanta

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock